One of my first posts in this community was in 2017, showing my use of the Nomad 883 to do small (~2") wooden tags (keychains). I am still at it; making the most of the 1.25" circle I have on these pieces, with inlays of various wood species without staining. I can’t do the big stuff with the Nomad but do have fun with ‘my miniatures’. Recent display I made from a door/cabinet manufacturer scraps. Annotations made on the photograph.

Nicely done! They look very well made

How are you cutting the pockets and plugs for the inlays? At first I was thinking laser attacment, but probably not on a Nomad. So probably a narrow vee bit?

Yes, please share - I’m just starting to explore how to do inlays with a shapeoko 3

Having trouble with my inlays.

What settings and bit do you use?

I had a small design to use inlays like this, but it wastes so much of the inlayed wood. I ended up just using the laser to decorate it.

@tinkereratheart Your tags are mighty purty, though! ![]()

Based on replies to my recent post, I will describe how I do my small inlays with references to a couple of recent .c2d files included in this new post. Toolpaths have been saved in these files. My process has evolved since I first touched the Nomad 883 in 2016, using Carbide Create in its 300’s version, all made available in my public library. With limited engagement with CNC experts, my methods evolved based on what worked for me and are likely not best practices or even standard practices - so take this information as such.

I use four primary end mills for my bases (BA) and inlays (INS) – for keychains and tags to coasters and family crests:

1 – a small 0.015”, (0.38mm) 2 flute cutter I buy from Oliver Tool Company on eBay (5 for <$20 + shipping: (5) - 0.38mm (.0150") Micro Carbide 2 flute endmills Kyocera K24501500.15M, | eBay). This cutter allows me to make my smallest inlays with corners rounded to a 0.008” radius. Its max cut depth is 0.045” to 0.050 depending on the cutter available when I order. I cut at 6500 RPM, 0.009”/pass, and 12 IPM. More aggressive cutting will break (has broken) this cutter in my hardwood. My standard inlay depth is 0.044”, to limit passes to four, to get close to the max cut depth of this cutter (4×0.009”) while minimizing CNC milling time. This is my approximation for a 1/64 endmill – which can create some artifacts with acute-angled corners but easily managed with its much lower price as compared to my checks on a real 1/64 cutter.

2 – Carbide 3D’s #122 1/32; generally using default settings

3 – Carbide 3D’s #112 1/16; generally using default settings

4 – Carbide 3D’s #102 1/8; generally using default settings

My process choices (visible in the attached .c2d files), kinda in sequence:

I have learned how to rapidly fix sharp corners, to get a 0.008” radius when needed. I don’t use the fillet all command because it distorts the vector coming into the corner. I depend on the corner tool and will modify nodes and convert curved vectors to poly-lines to get this tool to work efficiently and exactly where I want it. I love how Carbide 3D has designed/evolved the Boolean functions and I use them frequently. Processes to round corners quickly and efficiently, for the inlay work as I do it, is a separate topic.

I don’t use the 1/4” cutters, using thin hardwood strips 8.25” long (to span the wasteboard with ‘extra’ on each end), 1.75” wide (or less) and typically 0.25” to 0.080” thick. I don’t mess with collet changes; I stay with the 1/8” collet.

My wooden tags (keychains) bases (BA) are just under 2” long (allowing for the kerf from a 1/16 cutout to consistently give me 4 items from an 8.25” x 0.25” strip). See attached file as examples.

I use double sticky tape (xfasten.com; woodworking tape, 1” wide) for my hold down; I cut to within 0.004” of wood depth on the BA and within 0.003” on the INS (generally). Cut pieces stay together and remain attached to the wasteboard, but do pop-out easily or with some Exacto blade coaching.

I use the paper method of finding initial Z zero and the bit setter for subsequent cutter changes. I use the plastic/slick cover from the double sticky tape; this gives me a consistent means to “feel Z zero” and have found it more consistent than the automated BitZero probe. But I do use the BitZero 1/8” probe shaft, rather than a cutter, because it gives a more consistent measure of Z zero (considering wood grain and a good flat bottom on the shaft – compared to an end mill with flutes).

My INS design is an exact duplicate of my BA design – EXCEPT it is a L-R mirror image. I create the toolpaths for both the BA and INS in the same file, different groups because I don’t do them at the same time; this allows me to confirm, if needed, that my designs are exact duplicates at any time by flipping (mirror-back) the INS and checking alignment to the BA design.

I am frequently asked why I don’t use a Vee bit to chamfer my INS part. This is my rationalization: 1) I have more cleanup to do if I use a Vee-bit. I have two more cut lines that produce wood fuzzies to cleanup, 2) As long as my INS is 2” or smaller the normal process of cleaning away the fuzzies (see the next bullet below) will ‘break the lines/edges’ on the INS enough to get an easy fit, 3) it takes more time, another tool change, and 4) it puts additional/unnecessary stress on the smallest elements in the INS – that is, I can easily damage the INS in these small dimensions just due to wood grain variations. So the benefit of a chamfer with a Vee-bit do not outweigh the costs.

I mill the BA and remove the fuzzies in three cleaning steps depending on how the wood cuts. If a lot of surface fuzzies, I first use 320 grit sandpaper to gently remove fibers on the top edge of the cuts (with the carbide 3d up cut bits some of this is expected, and is acceptable). I then use a soft toothbrush and brush first with the grain and then perpendicular to the grain. Finally, for stubborn debris, I use an Exacto #11 to tease out fibers on the cut edges and in the bottom of the pockets. Goal is to minimize damage to the top of the pocket edges in the BA.

I mill the INS and remove the fuzzies but unlike the BA I start with the #11 Exacto blade to remove fibers along the top-side edges the INS and the top-side cut-out edge. I will then carefully use the soft bristle toothbrush to clean edges and corner pockets; fine inlays, like the O’Fish are only 0.020” wide, while standing 0.044” tall and require careful cleaning because it is easy to damage fragile elements with lateral sweeping motions…while courser inlays, like in the Paw-Heart file can be easily cleaned with more aggressive brushing.

I will sometimes use a small sewing needle (or canned air) to dig out debris hiding in text or small pocket corners (on BA and INS) especially the letters S, H, R, E, B, N, etc. It is no surprise that debris left in a pocket, in small designs, will impact results.

The O’Fish file is one of my most detailed designs, and depends heavily on the 0.015” end mill (I referred to as #14 in my tool library) while the Paw-Heart file was designed around the use of the 1/32 – to be fast and easy. Sometimes my text is so fine that only the 0.015” can do the pocket cut…but whenever possible I use the 1/32 to cut as much of the pocket as I can and then use the 0.015” as a contour on the perimeter. The 1/16 can also speed up milling if there is enough material to remove that it overcomes the cost of a cutter change. Carbide Create Pro lets me do rest machining for the corners but I have found I can do a contour nearly as fast. By staying in the ~1/64, 1/32, 1/16 series I can easily enlarge by a factor of 2 to re-use a keychain design in a larger (coaster for example) size.

Once both BA and INS are clean I do a dry check. This lets me confirm the fit and find visual points of reference that I will use when I am ready to glue. I know I have a good fit when the INS sits on, and will not slide on, the BA. I do not attempt to check the fit by pressing the INS into the BA at this point. It is possible to wedge the INS into the BA, even with finger pressure, or with a less than parallel seating – and the design can be broken by trying to get it apart.

The O’Fish file deliberately leaves elements of the design ‘exposed on the edges’ so I can view the fit. The Paw-Heart file uses a more generic approach to cutting out the INS. The requirement is to clearly see points of reference to help confirm a good fit for the INS in the BA. Every design is a bit different for me.

Initially I did not glue the INS into the BA; there is a tight friction fit and I finish my work with three coats of oil-based rubbing varnish that seems to seal-in the inlay well. When I began selling the tags, I started to glue the INS in, just to be sure. Over 7+ years I have never had an inlay come out of a keychain or coaster. I spread a thin layer of PVA glue (low viscosity better; brand doesn’t seem critical) on a smooth surface and then place the INS into the glue-film as if it were an ink pad. This puts a thin layer of glue on the surface of the INS, what will be inserted into the pockets on the BA. I take great care to keep glue off the side walls of the INS which will create uneven friction and crush wood edges that will create imperfections. But I do try to get all of the INS with some glue (the dot on a “lower case i” can be a challenge – sometimes requiring extraordinary measures).

I use strong lighting and magnification (i.e., reading glasses) to place two to three points of the INS, with a light layer of glue, in perfect alignment with the BA. I have to do this quickly because the thin layer of glue will dry/be absorbed into the wood quickly. When I feel the fit, I press with my fingers and usually feel the INS beginning to enter the BA pockets. It is important to NOT press one side all the way in, the INS needs to go into the BA evenly (as level as possible)…even a slight angle on the INS will crush edges on the opposite side when pressed in (because trigonometry).

I then use vice grips with thin pieces of plywood, to prevent marring the BA and to spread forces across the surface of the INS, and ‘walk around’ the INS pushing it into the BA until it is evenly ‘inserted’ (maybe 15-20 seconds); there can be a small gap between the INS and the BA, sometimes there is no gap. Rarely do I see glue along the INS boundary with the BA. This only requires monkey squeezes when all is going well.

Because the glue can expand as it cures, I keep the vice grips locked for a minimum of an hour – when I am doing large batches I will sometimes move these single clamped pieces into a stack and use a larger dedicated clamp.

Once glue is adequately cured, I have some choices on removing the backing on the INS that sits above the top of the BA surface. I have tried milling, belt sanding, and hand sanding. Generally the thickness of the INS backing, that has to be removed, is only about 0.030” (starting with a 0.080” piece with a 0.044” design depth). I can hand sand that, in walnut or cherry, in about 1 minute. I can do it on a belt sander, but it can get hot quickly and can cause damage. Care must be taken on a belt sander to not ‘snipe’ the surface of the BA. Milling requires careful/level remounting in the CNC and slow speeds to avoid tearing the INS, especially at corners; I use the CNC when I am doing coasters, large areas of INS, or especially tough woods to sand down (i.e., Maple). I find I can hand sand my keychain sized inlays in a couple of minutes, less time than setting up the CNC and with more control than a belt sander. I start with 80 grit until I see the BA come through, then I move to 120 to complete and ensure all is level, and then I finish with 220 on all surfaces before finishing with three coats of varnish.

If you have read this far and find this interesting and have a small design you’d like to see, let me know and I will try ‘making one for you’ and send it to you, if postage is reasonable, at no cost. As I said in the beginning my process evolved in relative isolation – so my only claim is that it works for me.

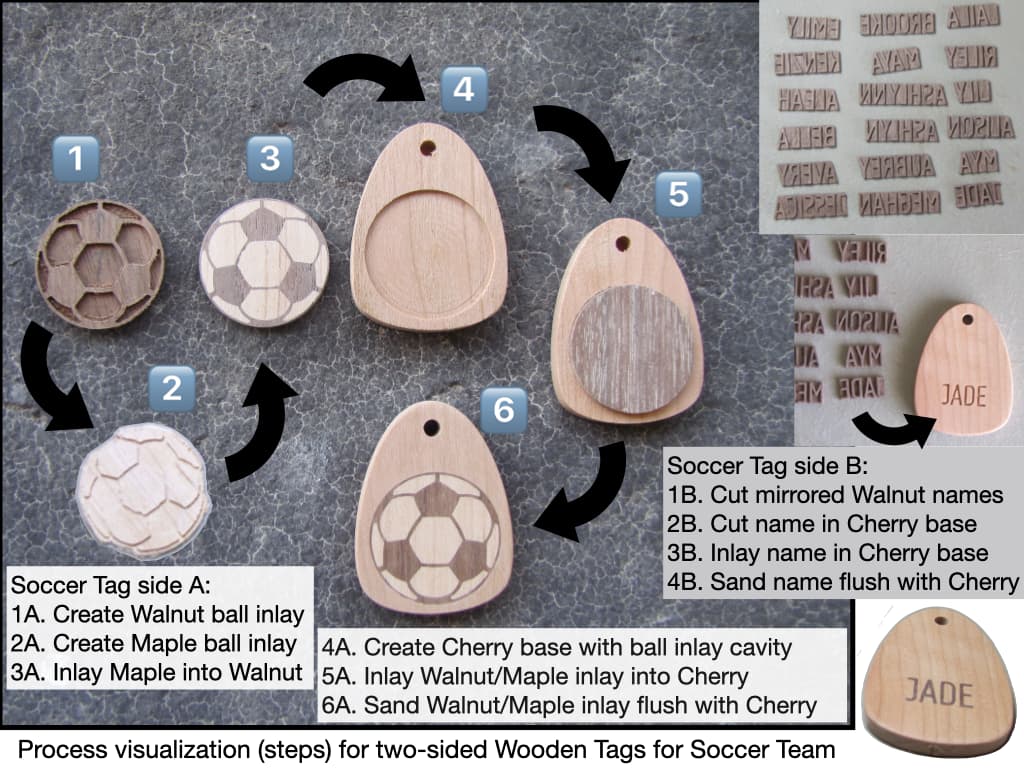

A recent picture I used to illustrate the inlay process for a customer:

Paw-Heart.c2d (972 KB)

O fish.c2d (2.4 MB)

@CurtisRandall

@ScottsdaleSteve

@erict

@bcwoodcarver

@CrookedWoodTex

That’s an amazing tribute to your artistry and technical prowess. I’m hoping your potential customers appreciate your dedication.

![]()

HEY TINKERER: That is what I call a great write-up of the processes. It was fun just reading down through that. Also, looking at your Tags, they also look great!

Nice work! Congrats!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.