Sorry so long just trying to give ya the info best i know how. I am a green here so trying to learn, but i am stumped as to what I have done!! Sure its something simple. I have a shapeoko 3XXL, with the latest carbide create and carbide motion versions.

Now I am just doing something simple to learn.

Put in tool then hit resume, it goes to bitsetter does its thing comes back to front center then i use probe successful. Then download file and turn on hit start. 1st toolpath starts cutting words no issues. Then if i have a 2nd line of words no worries it cuts. PROBELM is when it gets done with last letter it raises alittle and stays there dont move.

It is time for last toolpath cutting the sign(square) out. I just put a 1/4 tool in this toolpath. It never tells me tool change. it just stays put. cant do anything but shut it down…

Thanks for your help JD…

Please post the file and G-Code in question and we’ll do our best to puzzle this out with you.

woodshop.c2d (168.6 KB)

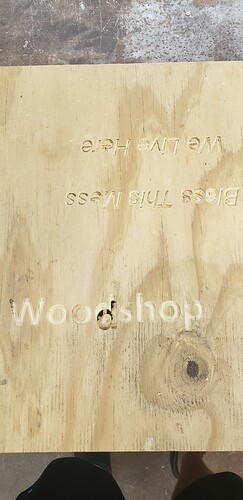

this was just a test to see it i could do something . cut out of scrap piece plywood … maybe this will help IDK if i gave you the correct attachment…

Thanks JD

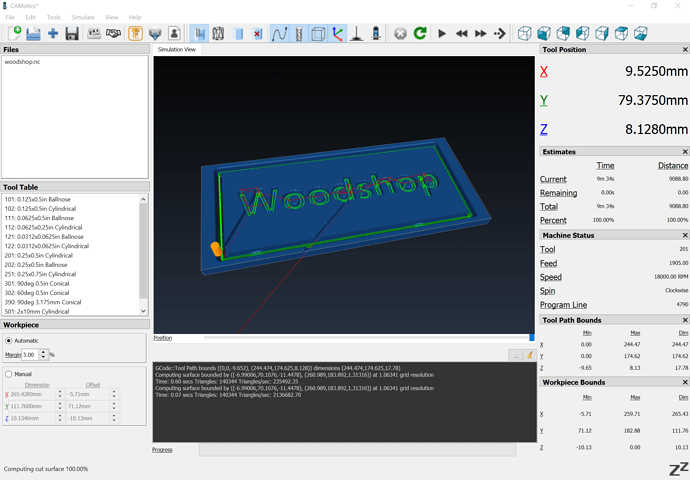

Not seeing that in the preview:

Could you post an image of the cut piece?

I’d suggest checking your machine mechanically per the checklist:

and see how it works out the second time.

This is the other side. The words up top was 2 toolpaths. It did same thing went up and stayed there. Never gave option to change tool

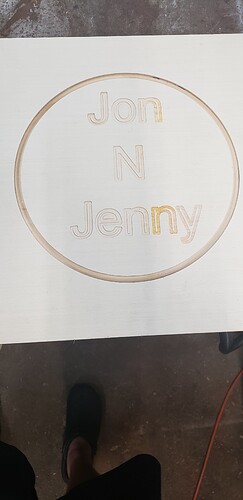

This one was 4 toolpaths. Stopped gave me option to change tool did bitsetter and all. It was a learning oops didn’t go deep enough… Lol… however this was done on a POS computer that came with it. . The other jobs was done on new puter I started using. Could some parameter be off somewhere? Setting, clicked box etc…

First concern is were the parameters for machine type/Z-axis type set correction?

If so, are things sound mechanically?

I’d try a very basic test cut in some stable and inexpensive material (say MDF) and test one aspect of the cut at a time to work out how things are interacting.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.