I was told this was a lever for a windshield washer fluid pump. The customer said they have broken 4 of the plastic versions…no idea how. This came to me through the owner of a race car shop, which is also the manufacturing manager where I work. I asked if there needed to be any weight reduction cutouts, and was told no. So a quick draw in Fusion and off we go…

I made some test cuts to get some idea on feeds and speeds and to calibrate steps if needed. I ended up finding out I had some bad wheels on my gantry and replaced them. After that, my calibration was perfect and started off with 0.1DOC, 0.05WOC at 30IPM, lowest setting on my Carbide 3D router using a 2 flute SpeTool aluminum cutter.

That worked fine for a while until I got my first chip weld…oof. I dropped it back to 0.050 DOC and finished her off.

It was very satisfying when the flip side broke through and matched up.

and yet again another evidence that a chipload of 0.001" (which is almost perfectly what these settings result in, after taking chip thinning into account) is a magical number for aluminium

Very well done, that’s a much more complex piece than many people’s first aluminium parts (myself included)

Now max out those RPMs! ![]()

nice outcome!

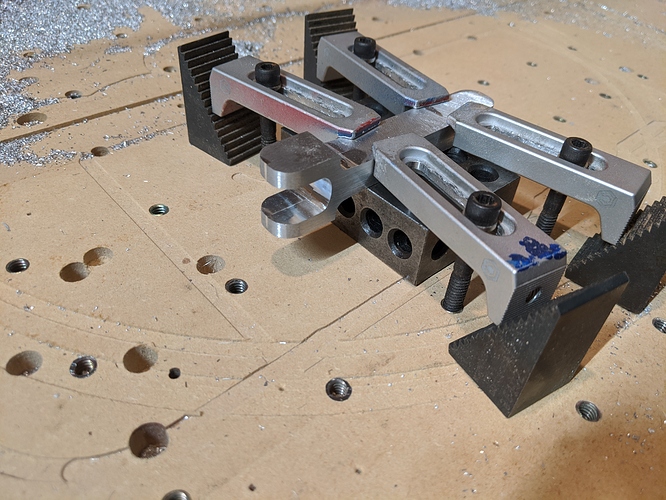

how did you locate the part on the 123 block?

I only had the two holes. I “indicated” the edge of each end with the edge of the 1/4" bit and 0.001 feeler gauge. Then walked over to the center from there.

Where did you get the black riser block?

They came with a set of clamps from Harbor Freight.

https://www.harborfreight.com/42-piece-machinist-clamping-kit-90752.html

Neat that those are back in stock — for a while only the Imperial (58-piece) set was.

I found out that this lever is for the pump used in a local Ford dealership for the windshield fluid. Not on a car, but to the pump they use to put the fluid into cars.

Neat!