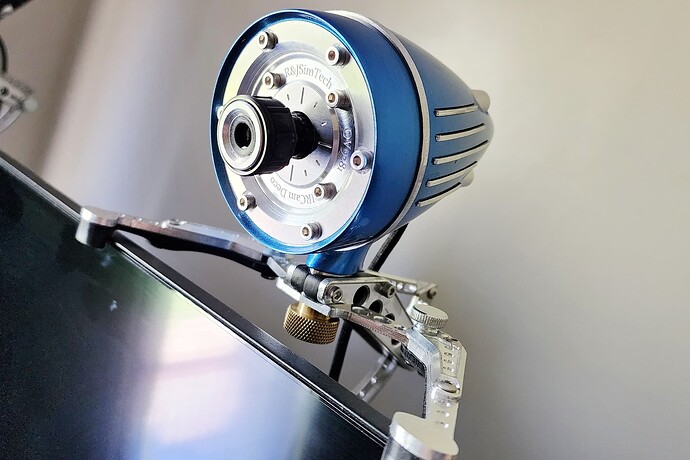

Here’s my first product produced with the shapeoko 5 pro. This is the IRCam Deco, which is an infrared head tracking cam for flight sims. It joins the IRTrackStar, a wireless infrared led clip, that I’ve been selling for a few years. The cnc has allowed me to expand and provide a complete tracking package in-house. You can read more about them on my site: https://rjsimtech.com/

Very Cool! I assume that you are only manufacturing the mounting bracketry on the S5P. Are you also making the faceplate and camera lens housing? I would venture there are better avenues than 4-flip machining that billet teardrop housing and turning your own fasteners. You’ve clearly got a very niche market with trusted suppliers and make a high quality product. Awesome work.

You are correct sir lol All of the aluminum is unpainted so you see the bits that are milled on the 5pro. Everything else is printed on a Elegoo Saturn 3 Ultra at 12k xy resolution with 50 micron layer heights. So extremely smooth. It’s a resin printer, not an FDM printer, so no layer lines. And I use an abs-like resin that’s very durable.

All the metal pieces are cut from a 6x8 plate of 3mm 6061 aluminum. I just use painters tape and super glue for work holding, and tabs on each part to prevent breakaway. Then touch up with my dremel to smooth off the tab marks. With the exception of the ‘Deco lines’ on the side of the main body, those are cut from 1.5mm 6061 AL. But all the cuts are non-flip 2d cuts. I use a 1/8" flat end mill for most of the cuts. The chamfers are done with a 1/4" chamfering mill, and the inset portion of the face plate that has the text engraved in it is milled out with a 1/4" flat mill. I also use the 1/4" chamfer mill for the engraving using the vcarve toolpath in carbide create.

I also brush the back side of the parts using 180, 240, and 320 grit sandpaper. Since I’m not flipping the parts and the backs are just flat, the brushing gives them some character. I setup a jig so I can keep the brush markers linear.

The 3d printed parts just get a coat of black primer for a matte black finish. No sanding needed since the printers I use are extremely high res. For the painted options, I do sand them up to 4000 grit before and after priming. I airbrush the paint with no sanding. Then a coat of polyurethane applied with a sponge brush, followed by a light sanding, then a final coat of poly.

The webcam is a OV9281 by Arducam. But since I’m making these as an infrared head tracking cam, I also have to print the parts to make the infrared filter cap. It uses a 6mm by 6mm optical glass infrared filter at 940nm pass through. The cap just slides on and off to make focusing the lens easier, as well as to use it for face tracking which uses an algorithm to track the user’s eyes rather than the ir leds from the head mounted clip.

Oh and the aluminum cylinders on the back of the tear drop are just aluminum bolt spacers. I don’t mill those.

Very cool process. Here I thought the housing was anodized aluminum, and that the plastic/rubber feet were also milled. The engraving on the faceplate is a very nice touch. When building my laser enclosure I did some research on the filtration of light waves, but had no luck sourcing reputable material. You must have a background in aeronautics to have developed a webcam system specifically for flight simulations. It’s amazing how available technology is these days, but I cannot find basic American made textiles. Props again, you’ve got quite the creative mind.

Thanks man, I appreciate it. I’m actually an industrial designer, but I grew up in Wichita KS, which is the air capital of the world, so I’m always able to go fly whenever I want. No pilots license, just know a lot of people with planes lol

A laser engraver is next on my list of toys for the shop. For the material, you’ll need to identify the wavelength of light that your laser produces, then search for panels with coatings for optical block filtering at that wavelength. I order every single component for both my cam and led clip on Amazon. Well, with the exception of the m12 lens mounts, I order those from Ali express because they’re a Chinese standard size that I can’t find in the US for less than $10 per mount, and since the size of the mount is standard in China, I can get a bag of 100 of them for $12. Including shipping lol

For reference, here’s my two main competitors for head tracking cams… Performance wise, my cam is an improvement over both due to the ir filter that I designed, but most of the performance comes from the IRTrackStar, which is the head mounted led clip portion of the system. That clip works with any infrared head tracking saytem, so it can even be used with these two here. However, in terms of build quality, it’s not even close lol Trackir cam/clip combo is $175, and the Delan Cam 1 and clip is $98. My cam and clip combo runs $233. The fact that I can turn a profit and make $30/hr building them, and this my competition, and the price is as close as it is, tells me they’re either not trying, or they’re robbing people lol

Therein lies my problem. I try not to purchase chinese stuff, especially for safety reasons. While their optical glass will be fine for you to obtain the signatures of the LEDs used, I wouldn’t trust the glass or plastic amazon sells to protect my retinas. I purchased my “safety glass” from JTech lasers. While they don’t make the material, they do vet the material by performing tests with their own calibrated meters in house.

The headgear with 3 points of reference is pretty smart! Perfect to map movements by calculating the change in angle, and the lower reference point being offset forward assists in accuracy for pitch. Mounted to an existing headset is also quite ingenious!

Oh the optical glass filters are made in the US. The only Chinese component is the webcam and m12 lens. Mainly because options for webcam sensors made in the US are extremely limited, and none of the options would work for what I needed, factoring in frame rate, infrared sensitivity, etc. But the metal and hardware are all American, as is the glass filter. I had initially ordered a Chinese plastic infrared filter and it didn’t filter much of anything. With the filter I use, the only thing the camera sees is the 3 leds. Everything else is pitch black.

Thanks for sharing.

My current head tracker mount:

Minimalist to say the least.

You’ve inspired me to up my game!

Haha Go big or go home ![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.