A while ago I started playing around with using the dovetail bits in my Shapeoko4. The use case is making lids for for covering teapots, coffee mugs and the ultimate a 12inch frying pan.

After noticing what happen to a bamboo teapot lid we had which after time due to the heat and moisture, all the glue joints broke down. So I realized 2 things. First, the lid had to be made of a single piece of wood and second the handle had to be attacked with some method that did not rely on glue. After seeing what people were selling on Etsy, I realized that had to be a dovetail.

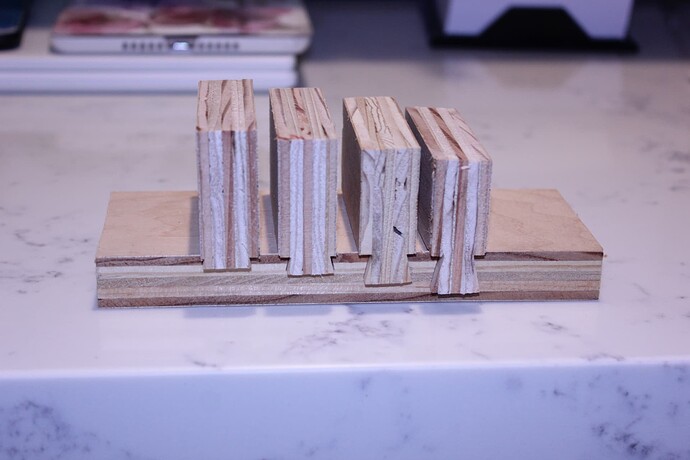

So I started playing around with dovetails. Using some simple calculations, and using carbide create to create the appropriate contours. I did some experimentation on scrap wood.

The lesson learned is that a separate tool had to be created for each dovetail depth as the diameter seen at the surface of your stock will differ.

So here is my first lid

The lid is made of oak and handle of cherry. The dovetail end of the handle was cut using the S4 as were the grooves on the side. The top end was just a roundover bit on a trim router. As the ends of the handle were square, I had to sand the handle to match the curve of the handle with a strip sander.

That was the small one. I’ve made several intermediate size lids, but the large one is this one: It is 13" across

My wife suggested I engrave something to personalize it so I engraved the year. The slot in the middle is a dovetail notch. I put a walnut handle very similar to the one in the photo above in.

One word of caution, add a little more slop in the dovetail. Though I put glue in grove, I probably didn’t need it. I was barely able to put the handle in pounding on it with a 3 pound hammer.

I guess I didn’t take a picture of it the finished lid, if there is interest I can take and post one later also I can see if I can dig up the c2d files though they are very boring, just circles and rectangles. The magic is in the width of the contours and the tool definitions