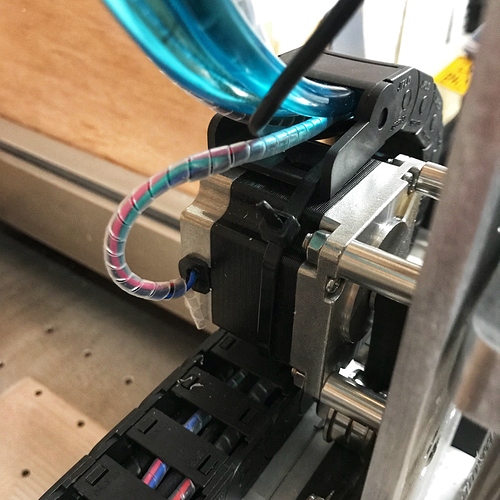

For the X axis, I used about 6" of tape on the left side, this holds down the section that doesn’t move so much. I then used a tie clip to attach it to the motor The motor is supported with 4 screws on my Z and everyone else’s, so seemed like a good place to go from. I did rotate my motor by 90 degrees so the wire didn’t get smushed.

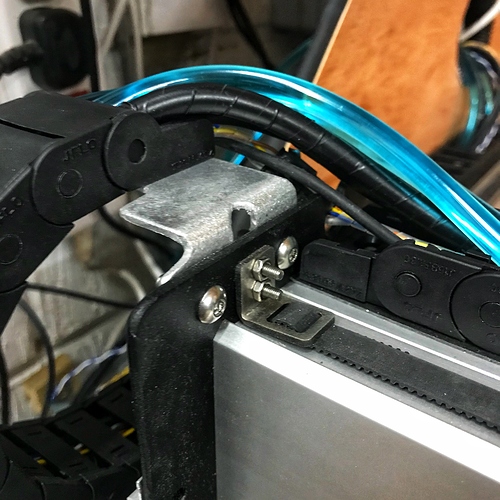

For the Y axis, I took the same approach with tape to begin art the very back then hand made a bracket, which can be seen here. This one is made from 2mm aluminium and I have a cnc design for a replacement coming shortly. It mounts to the stock holes in the frame. Here are pics of the hand made bracket.