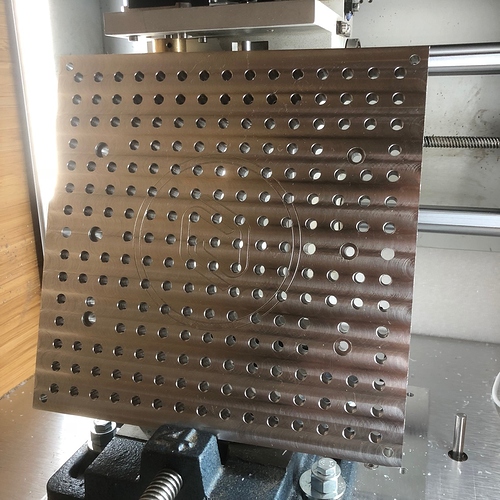

Just wanted to share some of the things I’ve been making for my nomad.

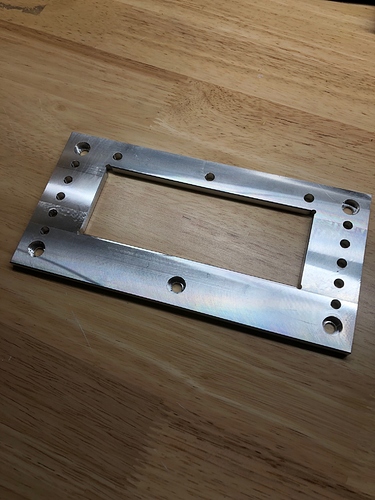

I wanted a metric threaded table, these are M6 x 1 threaded, 0.5’’ hole to hole. They have reamed holes for the nomad vise and flip jig. Those 4 holes at each corner was just for me, they are 3/16 reamed holes for locating diamond/round pins I use for my pallet setups.

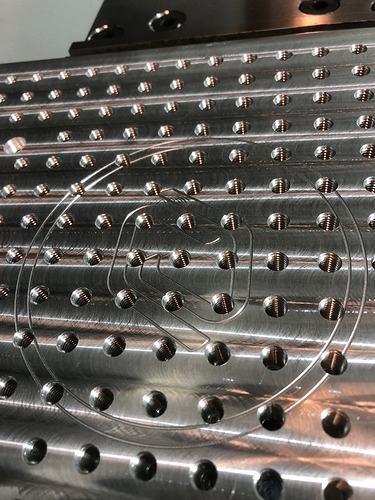

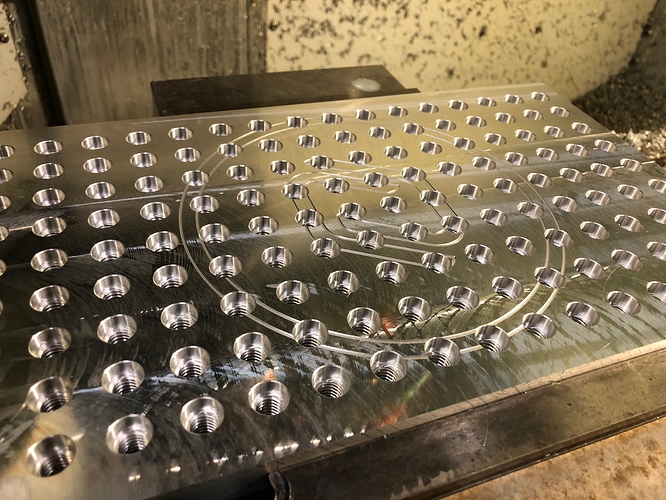

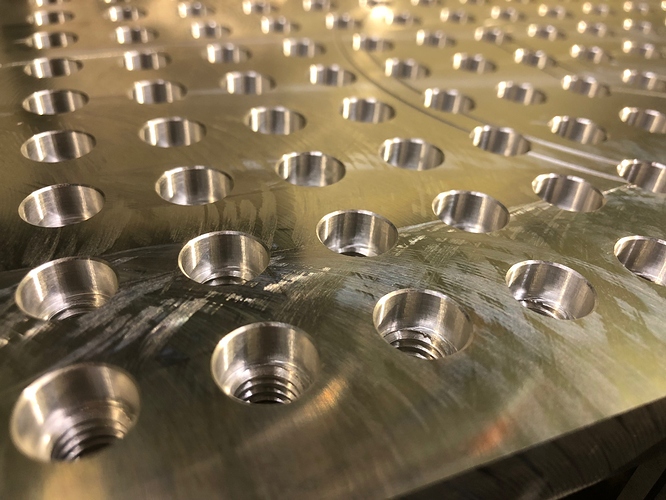

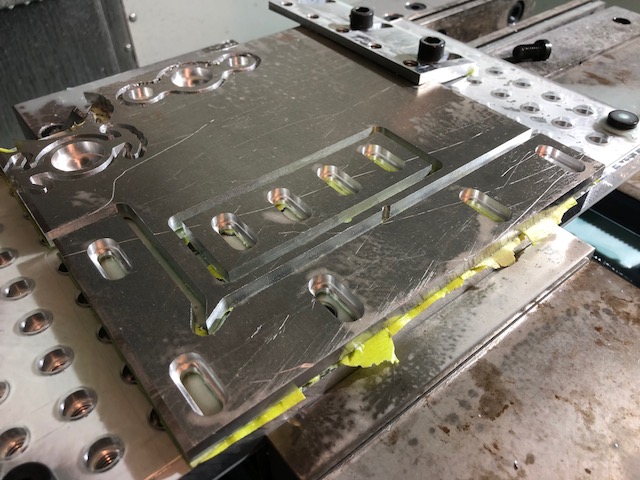

The above was v.1, I’ve recently thought about adding these dowel pin holes at the top of the thread, for more modular fixture work holding (Like Saunders Machine Works) Here is one I did for a much bigger fixture plate this one is 12’’ x 8’’ x0.625’’ thick. 3/8’’ dowel pins, with 3/8-16 threaded holes, 0.75 hole to hole centers. I have been recently thinking of doing this for my nomad table, but with 1/4’’ dowel pins and M6 x 1 threaded holes. Might have to go thicker than 0.5’’.

I never got a chance to snag those low profile vises so I had to make due with the 2’’ screwless vise. I didn’t like how I had to pull out the dial test indicator each time to line up the vise to the spindle. So I made this adapter plate so I could just bolt it to the plate, and just drop the vise in. The 3x mitee bite clamps secure the vise and keep it snug.

I have some other fixturing things on the way that I’ve been designing so I hope to have them done soon. If anyone is interested in any of these things, I could probably make a few extras. Just reach out to me and let me know. I’m an Industrial Design Engineering student and I’ve finally convinced the director at school to let me use the HAAS Super Mini Mill 2. I have to thank Carbide3D for making these little desktop machines because it was because of the things I made and learned on the nomad which convinced him that I was capable of not crashing their expensive machines, haha. This age of personal manufacturing has been nothing short of amazing, and I’m grateful Carbide is such a great company. Everything I learned on the Nomad translated to the HAAS.

I update my instagram more often if you’re interested it’s @chrislee.design