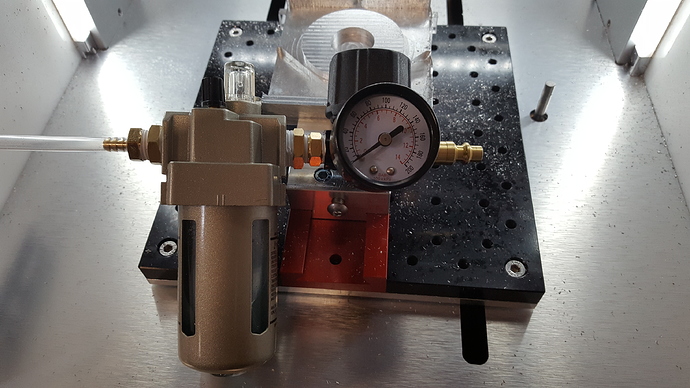

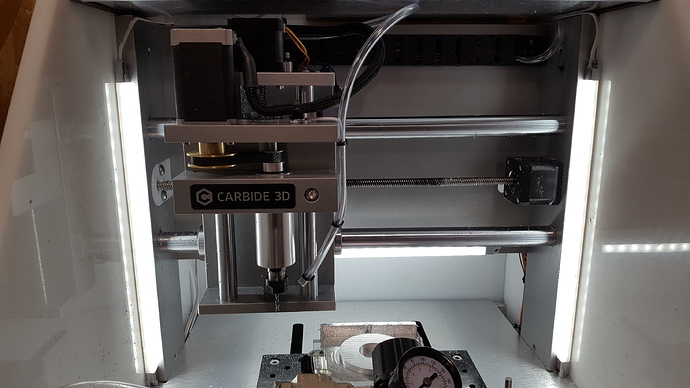

I have one of the standard, line lock style ones from Amazon for my SO3 XXL, but it was too bulky to fit the mixer block on the Z carriage and in the enclosure. So I put my brain to figuring out what I can do on a small budget and with readily available parts. I wanted to keep the independent air pressure and coolant flow of a mixer. Thankfully Harbor Freight has an inline oiler for air tools… could it work for coolant? YUP! I got their $12 oiler, a $5 regulator, a few fittings, then headed to Lowe’s for 1/8" ID tubing and brass fitting. So around $20 later I have an adjustable mister I can hook up to the compressor. I will design something a little more elegant to mount the tubing, and a way to mount the the oiler/regulator on the side panel, but a slightly longer bolt, a coat hanger, and a few zip ties later and it’s fully functional as a proof of concept. Around 15 psi of pressure should work well too clear chips and I can adjust the flow to a very light mist. It seems to need fairly constant, ever so slight adjustments over an hour or so, which is fine because the reservoir lasts around that long.

Nice, I think you have a smart solution. I see a small line next to your spindle, is this the new line you are using? Are you planning on adding a nozzle at the end to concentrate the flow? Is there a valve to turn off the air/coolant flow between the regulator and the spindle so you don’t have to mess with the regulator? Do you think the constant flow albeit at low pressure will make your compressor run almost continuously?

One thing I forgot to mention is that the oiler has a bubble at the top that you can see the coolant dripping into the air stream from. It is actually quite nice as it gives a very visual representation of the coolant flow.

The 1/8" ID clear poly tubing is what I am using. I have thought about a nozzle, but at 15 PSI it blows more than hard enough to clear chips easily. When I squeeze the tubing flat it does get more velocity, but at the expense of less area that it is hitting. I don’t think a nozzle is necessary, but I might get more velocity with less CFM and make my compressor turn on less. But I kinda like the slightly larger opening since it hits more area. This will definitely be an area I play with. I’m sure I can 3D print some iterations for nozzles on my resin printer and play around with it. Maybe even try a fan style nozzle.

I don’t have a valve in line after the mister/regulator yet. Honestly once mounted on the side of the enclosure, it’s super easy to get to. Also, I wanted to keep it to very easily found pieces at common stores, and I don’t think either Harbor Freight nor Lowes had a 1/8" ball valve. When I need to refill the reservoir, I quickly unplug the supply air hose, and the reservoir has a plastic bolt you can remove and fill it. Another cool feature.

At 15 PSI there is plenty of velocity for sure. My compressor is an older Kobalt 30 gallon, 155 PSI model. I have two 50ft reels, and the runs to get to them, so there is a bit of built-in volume in the system. It kicks on every 15-20 minutes or so. Since it is already high velocity at the spindle, I think a nozzle will mostly be to keep the higher velocity with less CFM, thus making the compressor kick on less.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.