What a wasteboard. I will drill and tap the table next week. But first the blocks and finish tramming…

Align everything is painful for me without the right tools and consecutive trial and error is my only way. I can tell i have made a few mistakes but i will live with them for a while.

Did i say i do not like tramming?

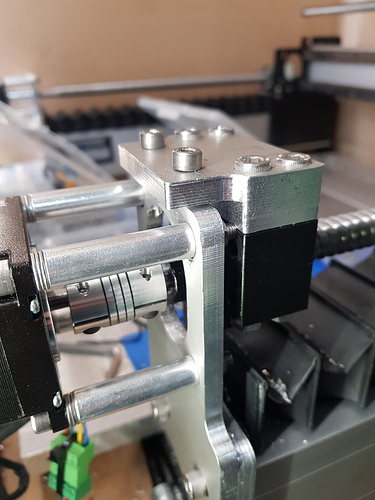

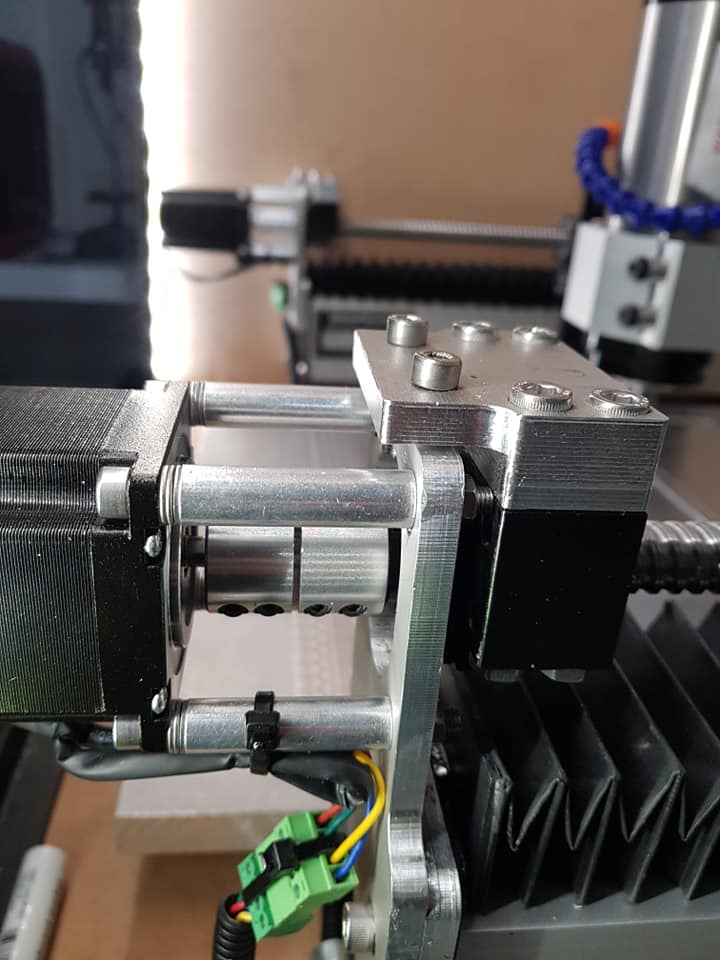

That machine looks really good. Like how you have customized the standard side plates to fit linear rails.

Question; what are the specs on those stepper motors and what is maximum feedrate on the machine now? Also is that SFU1605/1610 ballscrews?

In some ways, this makes me think of drag racing. The cars have an outer shell of one type of car, but there is almost nothing from that car left when it leaves the line! Aside from the “Shapeoko” label and the initial arms, what is actually still a Shapeoko? Did you update the control board as well?

Technically, it’s all a Shapeoko. @WillAdams can point to the official reference.

Alignment with rails can be very “fun”

For tramming just use a Z bar in the spindle, give it an 8" swing to cover a 16" diameter circle and you’ll be able to dial in the tram in no time pretty accurately.

Looks like you have flopped the y-axis plates to give more rear area work.

Your pic’s are helpful. I am looking at the same linear slides.

If you would, keep the updates coming on how you feel this improves or hinders.

@diegocolonnello

I am curious and hope you don’t mind but I have a question about your choice of the “ball-screw” drive.

Did you consider a helical cut gear on a gear track, or a rack and pinion gear? If so, what were the factors in your choice?

I can not remember ever seeing a ball-screw drive where the screw shaft didn’t end up with a bow or bend. Seem’s with those steppers you are set to run with a good bit of force and I wonder how long before one of the rods bend…

You see…I never knew about “the rules”. My post clearly is answered by Rule #10 and I’ve have a whole other thread dedicated to Rule #3

(You will be surprised by the accuracy of the machine, you will never get bored watching the machine work)

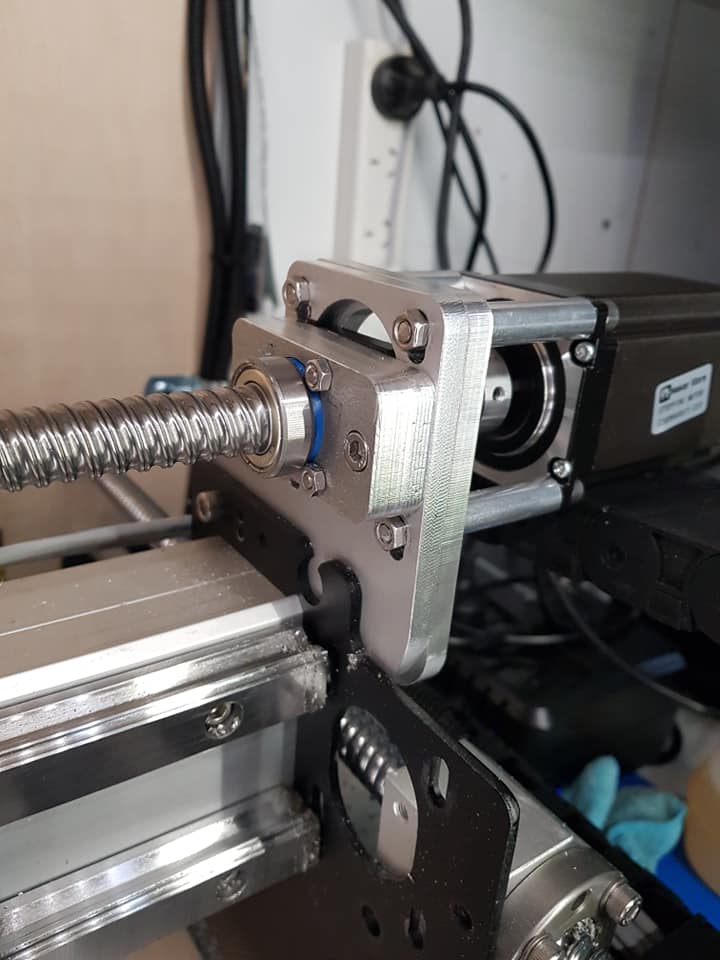

somehow the thing about the basllscrews not supported is a thing causing nightmares to more than one person, look, the machine is only 600mm x 600mm the overhang is allways less than 450mm, they are so thick that bending or like someone said, whiplash is not possible, and, is a 10 mm per turn so they spin slow and the axis move fast enough…

Anyways, i am installing the bearing block this weekend so everybody is happy and have good dreams!!! hahahaha

By the way, i saw this today:

can you imagine my machine with ATC?

yes i have a model of the machine on Fusion 360 and did part of the changes there, that was one of them, gave me a bit of clearance on y axis

might be happening today

YES of course it is a SHAPEOKO

What’s the issue? An FF/FK bearing block might be easier to install with foolproof alignment with your end plate design.

Made my own x axis bearing block. By the way, my M4 tap decided to live inside the X axis bearing block forever… and also, the block attacked me when i was drilling small 4mm holes on the drill press… ![]() one of those days…

one of those days…

The Frog Tape is so appropriate.

I can tell you I have made some parts with embedded tap pieces as well. I prefer to, mostly out of stupidity and desperation, break a reverse carbide drill bit on top of the tap just for good measure. Then struggle with some vice grips before attempting to grind everything down to flat then finally throwing it in the trash before starting over.

“By the way, my M4 tap decided to live inside the X axis bearing block forever… and also, the block attacked me when i was drilling small 4mm holes on the drill press… ![]() one of those days…”

one of those days…”

I occasionally cut or poke my self in the shop. When I do so I immediately stop and wash the area and bandage with Neosporin. I cannot afford to get an infection. I have a full industrial first aid kit sitting by the 1st of 3 extinguishers in the shop. I am a long way from a hospital and/or ambulance. Do yourself a favor when hurt, treat yourself immediately.

This reminds me of a famous UK comedy.

I’ve had the same broom for 20 years.This old broom’s had 17 new heads and 14 new handles in its time.