Wow, really? Was that new or did you buy from someone? If you buy it direct from Mechatron’s shop it seems to be 850EUR for the spindle alone!

remove the VAT tax…

Without VAT, it’s ~730 EUR, which is 1200 AUD, a lot more expensive than what you paid.

not understanding your logic

You say you paid 850 AUD (Australian Dollars).

The prices I can find are 850 EUR, including 16% VAT.

850 * (1/1.16) = 732 EUR without VAT.

1 EUR is 1.65 AUD, so 732 EUR is 1208 AUD, which is the retail price of a 2.2kW watercooled Mechatron spindle without VAT.

when have i said i bought my Spindle from Mechatron?

Spindle and VFD from an australian supplier

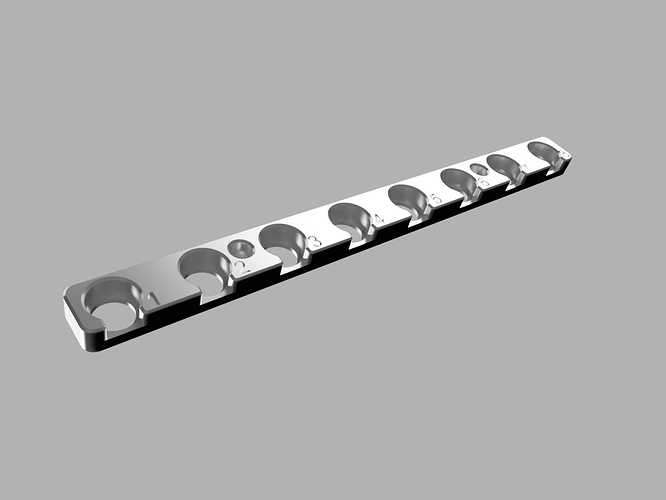

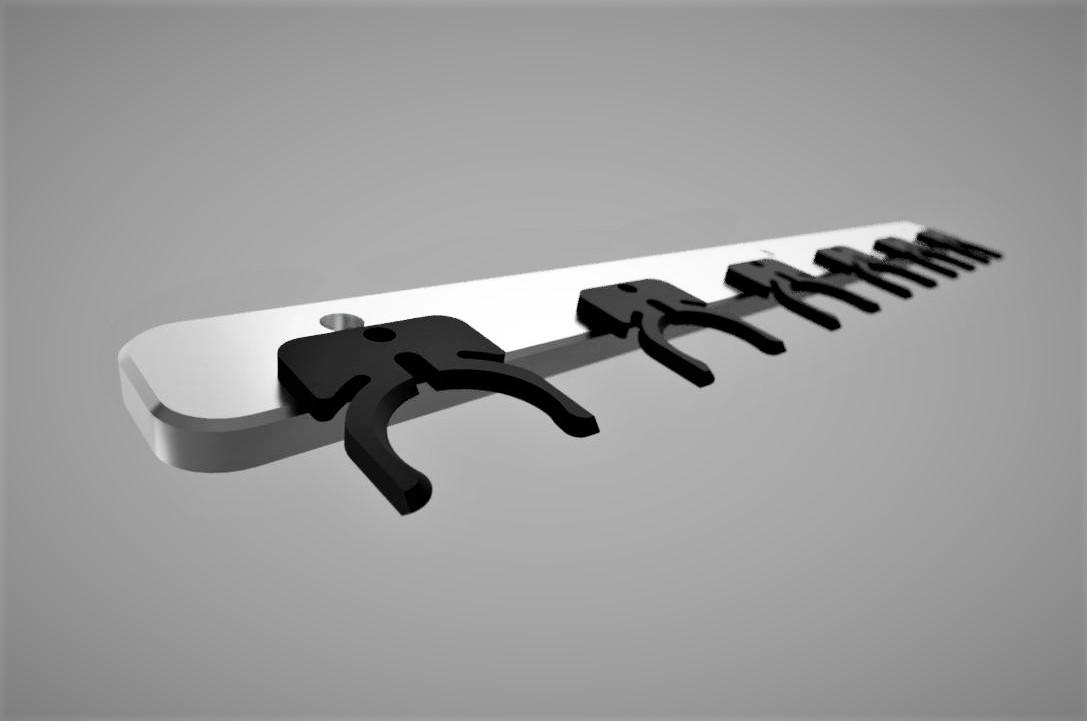

ATC adaptor from Mechatron…

Ahhh, that explains it. I just assumed you were using a Mechatron spindle with a Mechatron ATC.

otherwise i would have purchased an ATC Spindle at from them the first place

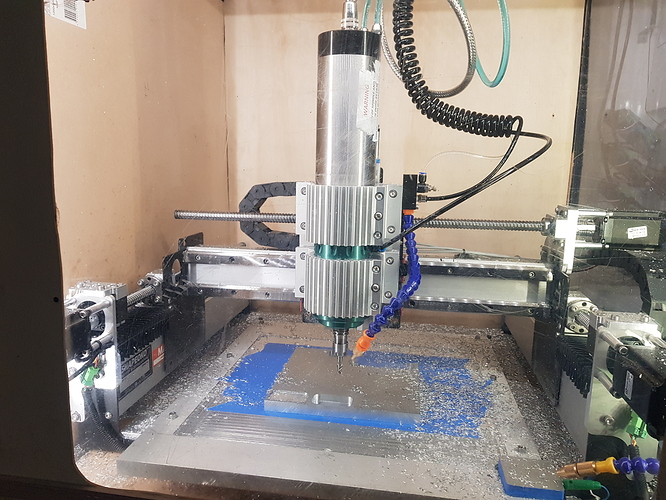

installation started and some test has been made to confirm the adapter works…

On a CNC group in Facebook a guy decided to troll me in German, and said the product was not a good idea and the pulling force of the adaptor was not enough… so i installed the adaptor and decided to run the same type of cut i did yesterday when i machined the new Z bracket… so far, success!!! same performance and i can now sleep nicely, i will do more tomorrow and hopefully start having auto Tool Changes…

Beware!!! it looks huge installed on the shapeoko, because it is not installed in a MILL format machine!!!

the complete assembly feels solid, but i suspected the black original steel plate on the z axis remains from the original shapeoko assy, was not rigid enough, so tomorrow i will make a new one (thick and beefy) to improve the performance, another thing i have to do is a bearing block for the z axis, all the weight this thing has is being carried by the stepper…

What’s the total weight of the spindle assembly? Do you have any issues with it back driving the ballscrew when the stepper isn’t powered? A small gas charged strut might be pretty cool to offset the weight, just like some of the big machines do it.

Have you given any thought to replacing the base with epoxy granite? You could also fill the Y rails with the stuff too.

@diegocolonnello I forgot to ask, would you mind sharing the reference of the bellows you used on that machine?

the complete thing is about 10 kg, the thing doesn’t even move when not powered, even if i pull it down, i have been thinking about doing something to compensate the weight, bur so far i have been lucky and does not seem necesary

a friend just gave me a cut of engineering stone, 900 square i will use it as the base for my new enclosure.

my Y and X extrusions are already filled with sand…

Julien, this bellows where stored on a friend’s workshop. he gave me a complete length and i ended using like 2% on this machine…so i have no idea about part number or model or manufacturer … i have seen them on Alibaba but never got to order them… do you need some?

this are for 20mm rails… i can post detail photos later.

These guys are the ones I’ve been eyeing up.

Be interested to know if anyone has bought anything from them.

This needs a video!!!

I remember doing some searching on Ali and concluding “yeah there’s like a 50% chance that I get it wrong somehow and it won’t fit after waiting for 5 weeks”, so I gave up. If you are willing to sell me some length of those for the three axis of my SO3 (I have no idea what bellow length that would mean) that would put that idea back onto the table. I’ll PM you, thanks!