When I was looking it seemed like the US Xometry delivered to the EU as well though?

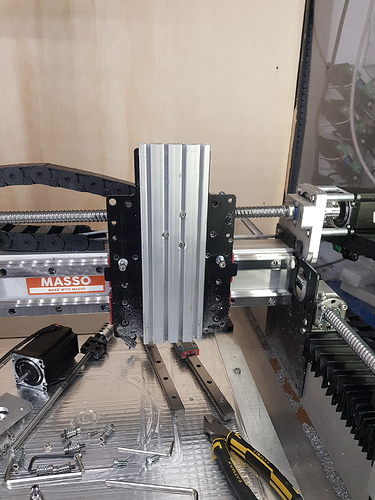

Original Black X axis Plate goes out!!!

Gone…

New one installed!!!

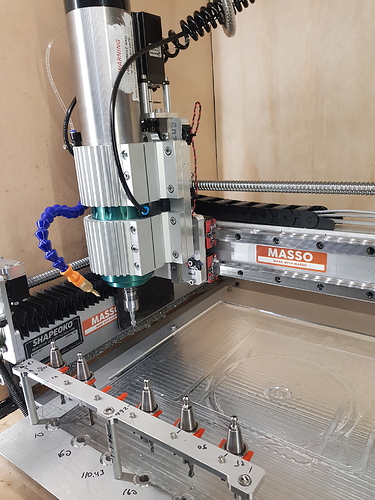

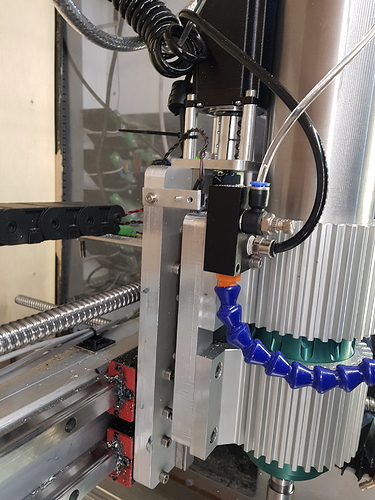

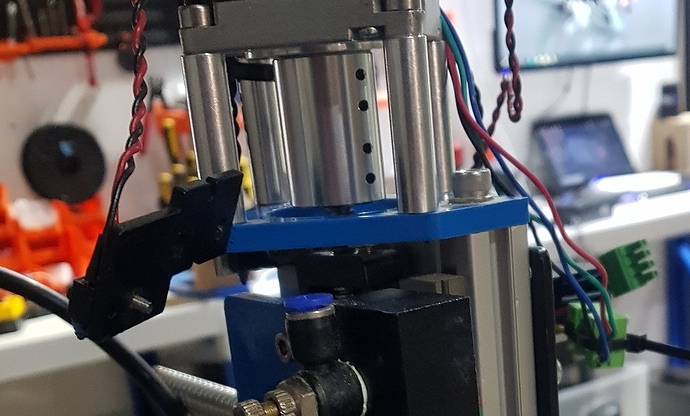

The blue Z motor plate GONE, also rotated the motor 45 deg to gain some clearance for the spindle.

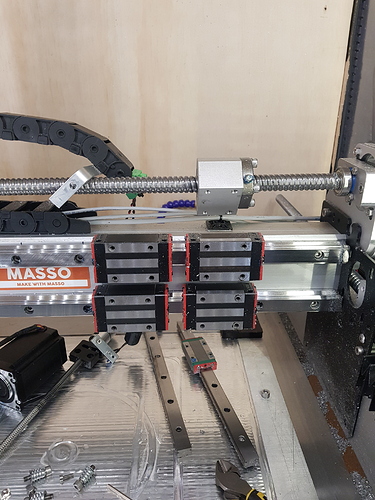

With all this changes i managed to remove some spacers i had between the spindle mounts and the Z plate, i shaved more than 20mm space between spindle and the frame, also Gained X 50mm x axis movement because the new X plate is narrower…

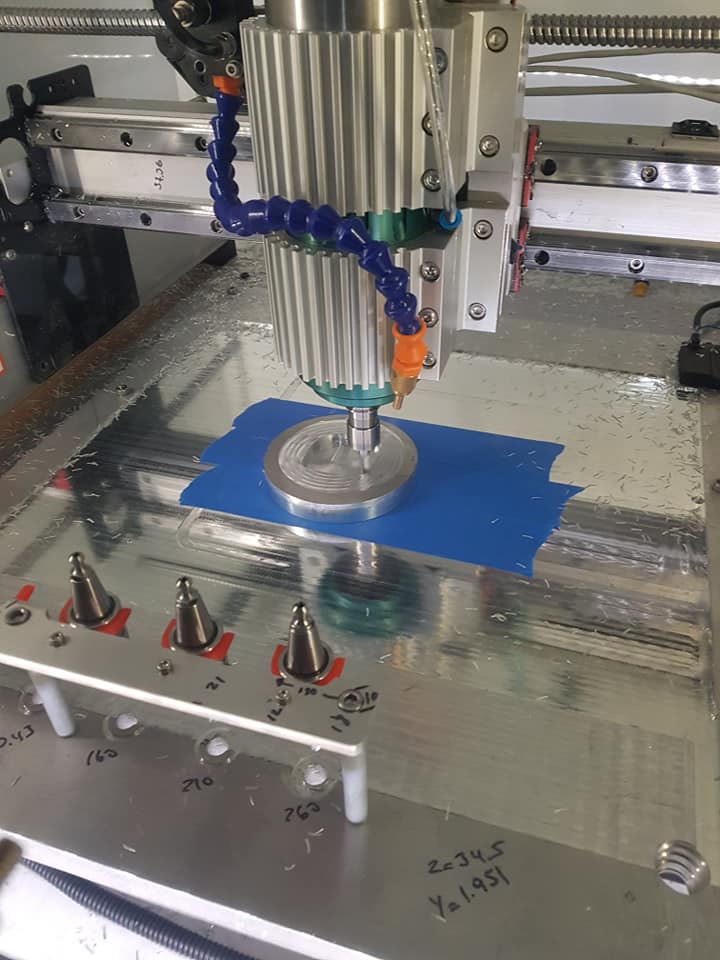

I was chasing the source for some shatter i had in some toolpaths, everythime it resonated it left a wavy mark on the finish…

Seems like the Machine is happier with the spindle a lot closer to the frame, And the new Xplate is stronger than the Black original…

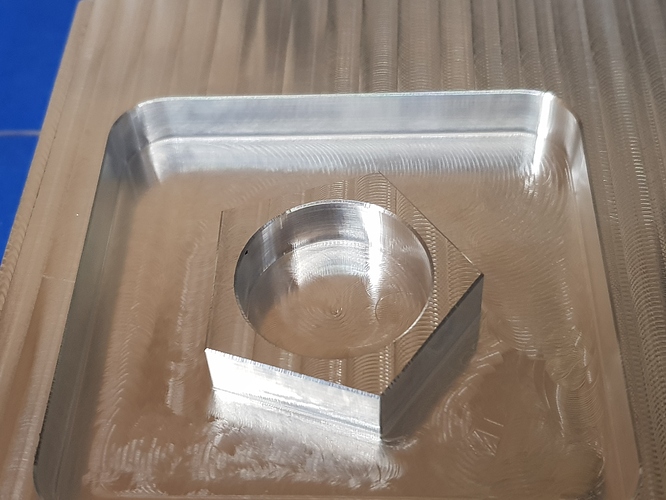

This is a test cut after adjusting all the travels, Tool positions ETC

I can now report, NO more resonance… smooth sailing all around… And bigger work area

Just realized i forgot to tram!!!

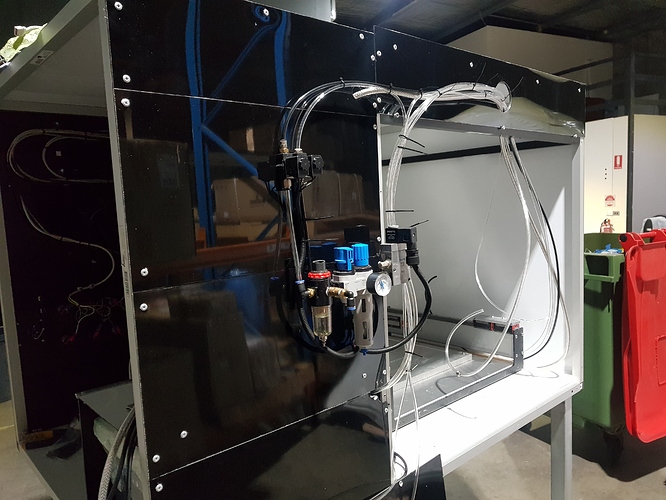

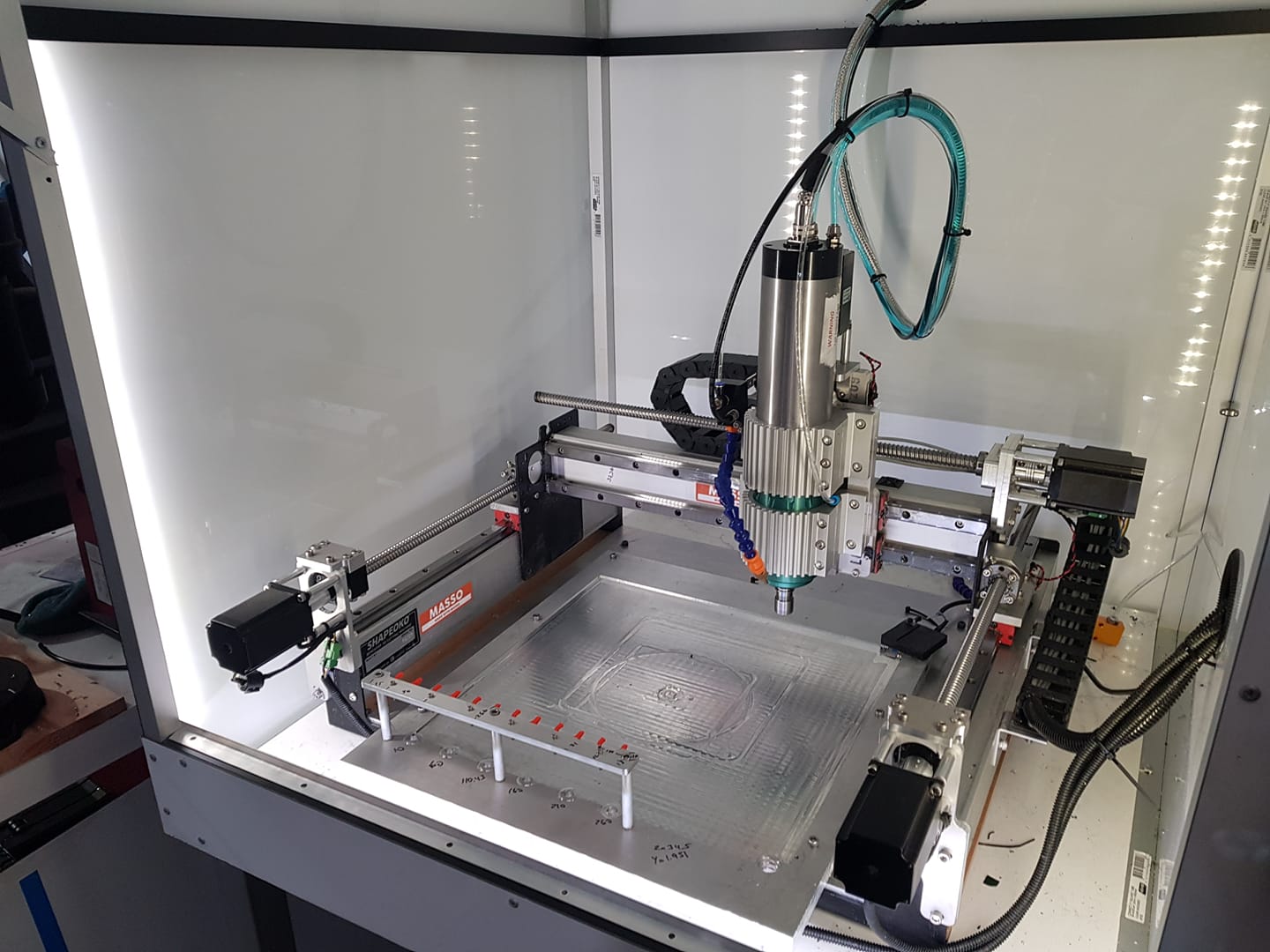

Started working on my new enclosure, a proper place to operate my machine and install all my equipment, electronics and pneumatic elements properly, sadly i haven’t found a way to surve the alu panels so it can have a better aesthetic appearance…

Steel base with lockable caster wheels and on top, engineers stone to ensure it is straight and level…

the top enclosure is a fame of aluminium sheeted with aluminium Plastic composite panels…

i will continue tomorrow… if my hand lets me…

On friday i fell backwards after loosing my balance and landed on my hand… this will maybe slow things down… i can’t even hold a screwdriver… i stuffed something on my wrist!!!

It took me a second or two to realize that this mysterious dome-shaped white thing was not inside your enclosure

Also, I dig your “garage” space!

Get well soon, we can’t get enough of your crazy mods.

Random suggestion: veneer? DIY Perks on YouTube recently made a really nice Aluminium + wood table with some veneer on the outside and it looked really nice.

Or just paint…

You’ll be better off using that area underneath to collect all the chips. That’s what I’m going to do to my enclosure. I’m sick of the chips build up around the machine and the constant need to vacuum them. Other than that, the enclosure looks great. What tube size did you use?

Rx Results are back, No broken bones… only soft tissue trauma.

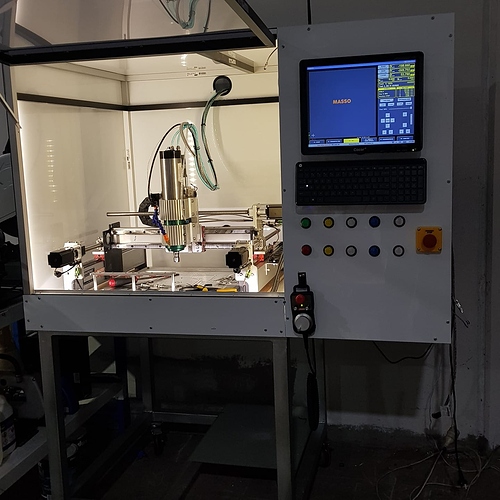

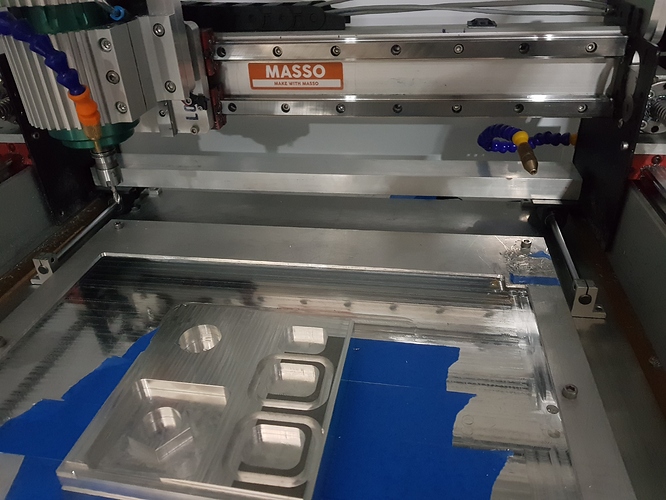

This is my Fugly enclosure!!! looks like a big Oven… found no way to bend the panels to nice curves, so this is it…

What will you do if you keep giving your Shapeoko steroids, and one day you come in to find the extrusions are huge, leveling feet are still tiny, ballscrews have shrunk, and every time you send a program you get an all caps response like “COME ON BRO! DOUBLE THAT DOC!! GET SOME!!!”

what will you do then?

This is a crazy amount of work to do in a couple of days…

Too much goes on this things… ended up super tired and i haven’t finished… long day tomorrow

This thing is absolutely incredible! Awesome work! It definitely gives me inspiration and helps newer users like myself see what is possible with a little (or a lot!) of modification!

So what are you going to call your “Shapeoko”? There is not much left of the original Shapeoko so you need to give your machine a name.

So here are a few suggestions

Frankenoko

The Beast

RoidRage

Cut yourself a nice sign to put on the back wall of your enclosure.

I have no idea… i saw a video of a Datron Neo and understood i can go faster. i started doing some test…

Sounds like an air raid siren, it must be a warning for awesomeness.

That’s some crazy speed for a shapeoko!!!

Courtesy of all the linear guide-rails & ballscrews

That sounds pretty good, especially for that cut speed in Aluminium.