I recently had the need to cut some copper sheet metal, so I decided to build a vacuum table to hold down the sheet material instead of using any double-sided tape.

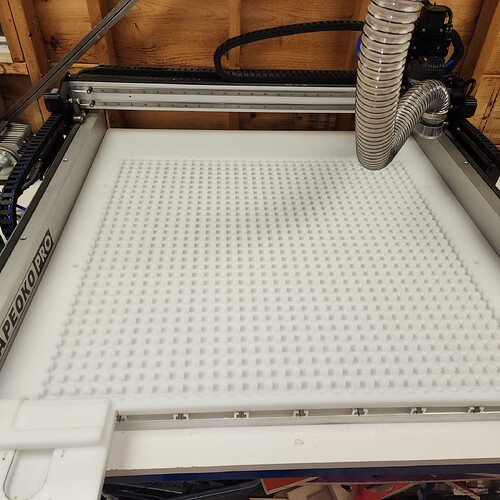

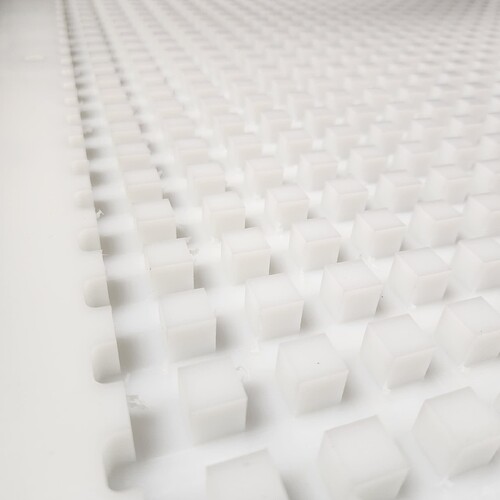

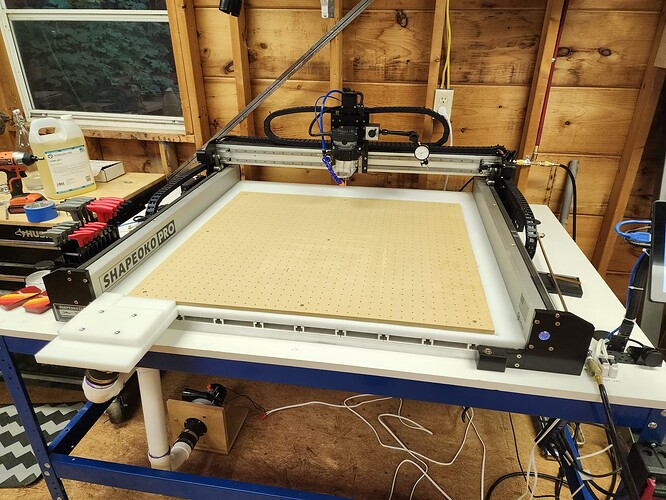

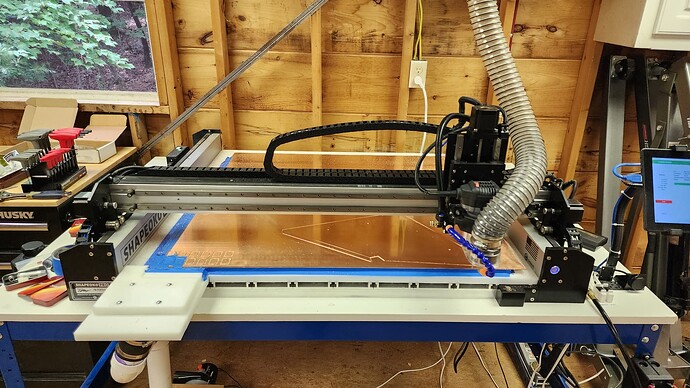

I took a 48"x48" piece of 3/4" HDPE from McMaster, and I cut it down to 40"x48" to fit into the machine bed on top of the tee tracks with the MDF slats removed. I then cut some channels into the material and shifted the material up to cut the vacuum hose attachment on the 8"x8" part sticking out at the bottom.

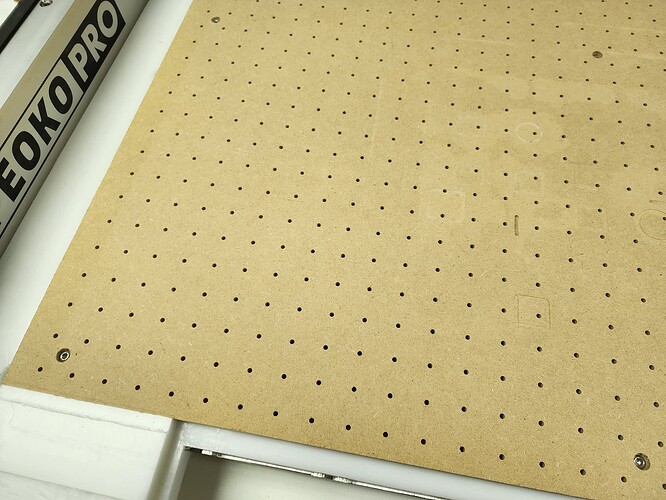

The HDPE sheet is bolted to the tee tracks with the same holes used to hold the MDF slats. I then bolted a 1/2" MDF sheet on top of the vacuum table and did a skim pass to flatten it before drilling a bunch of 1/8" holes for the vacuum.

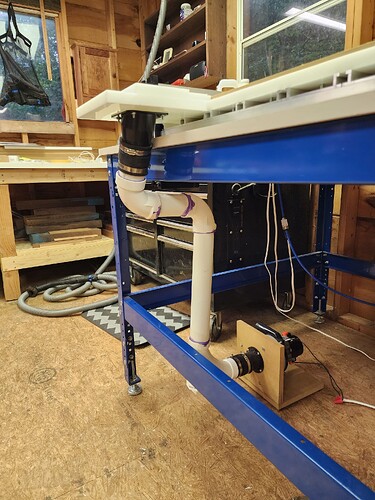

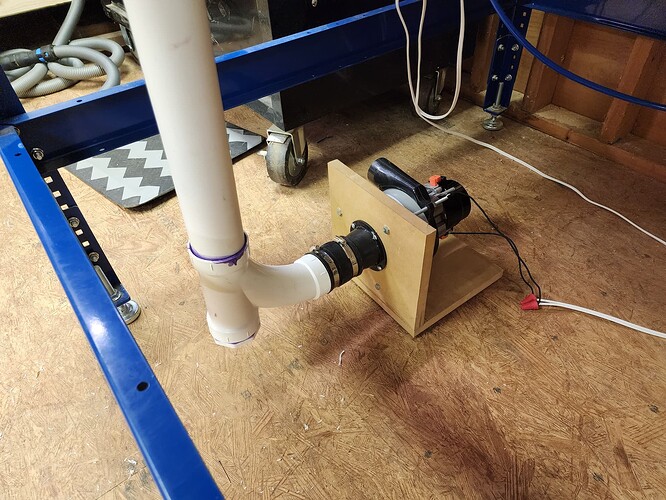

The vacuum is provided by a whole-house central vacuum motor under the table.

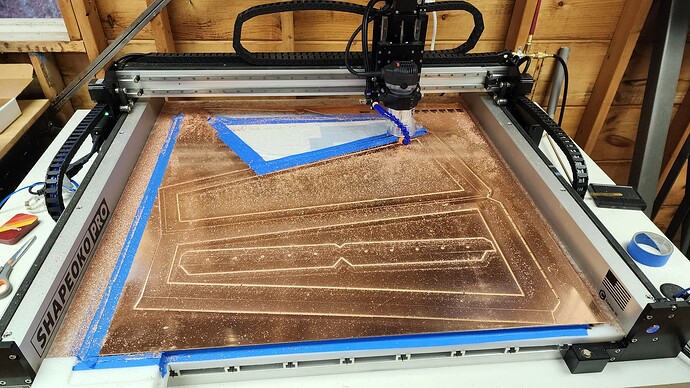

Here it is cutting 0.0625" C110 half-hard copper alloy.

Why I chose this design:

The piece of MDF on top of the vacuum table is 35"x33", which is the maximum area that I can cut up to the front of the table plus 1/2" all the way around that can be cut by the 1" McFly cutter when I skim the board. Since this spoil board is completely flat, I can load a sheet up to 40"x40 and then turn it around to cut parts on the top of the material that is outside of the cutting area. I did the skim cut with the vacuum on before I drilled the holes so the table would be flat when it was deformed by the vacuum, and I measured this to be no more than 0.010" deviation across the table with a dial indicator. The vacuum table is attached to the tee tracks with the same holes used for the MDF slats, so I can remove it and put the slats back if needed.

Things I would do differently:

I cut the channels in the 3/4" HDPE to 1/2" depth, but I should have gone only 1/4" deep to make the vacuum table more rigid. When I screwed it down to the tee track, tightening the bolts too much causes the vacuum table to bow at spots, since the bolts span the gap where the MDF slat used to be.

I made a mistake and mounted the MDF board 1/2" too high, and I can’t skim the top, so I will have to modify the plastic piece that I glued down to cover the vacuum hose connection at the bottom.

The thickness of the vacuum table on the tee tracks causes the dust boot to hit the edge of it when I am probing the height of the tool, and I have to take the dust boot off and put it back on after it measures the height. I should have removed the tee tracks and bolted the vacuum table to the horizontal frame members, and tapped some holes in the vacuum table to attach the tee tracks on to the top of it if I wanted to put the MDF slats back without having to remove the vacuum table.

Let me know what you think!