I don’t have a laser so I may be off base but what about an air deflector on the opposite side of the air assist across from the laser. Nothing very complicated but a piece of sheet metal in the shape of an L with a 135 deg angle. So you have the air assist the laser in the middle and a deflector that is just above the work surface that sends the air up and sideways. Smoke that stains the wood would be deflected maybe towards a vacuum hose.

I can picture in my head what you’re explaining, but I don’t know how well it would work. If I look at @ClayJar ‘s Smokesucker design above is pretty close to what you’re describing I think, except you wanna move it closer to the cut right? His leaves trails also. If I’m engraving I don’t use the air assist, and cutting I’m trying to get the air moving as vertically as possible. On larger lasers the air assist actually comes out of the same hole as the laser. So part of this issue is caused by the air moving horizontally because of the type of laser. Having said that I know even with larger lasers and proper air assist that smoke staining is an issue, so some folks use mask on their work.

I have a 50 watt CO2 laser on the way, with proper air assist, so maybe in a few weeks I’ll be able to share the difference in cut/smoke staining.

Dan

50W MUHAHAHAHAHAHAHAHAHAHAHA

Haha!!! Yes, I do believe everyone needs a laser!!! It’s not always the best tool for the job, but it has its own uniqueness that just doesn’t work as well with anything else. I hadn’t really planned on going bigger, heck I thought about getting a laser for a couple years before getting my XXL, then a couple more before adding the JTech. Now that I see what I can do I’m pretty hooked, I just need to do it faster!

Dan

Woahh… did you sell the Triple to finance such a beast?!

No I sold my soul to Visa, but the Triple is also likely going away. I got hit about a month ago (in my car) while sitting still at a stop light. A good friend at work who probably has 100,000 miles on the street had his bike washout from under him about 2 weeks ago (with a fair amount of damage to his body). I’m 47 years old and have been pretty lucky as far as accidents go, but I’ve got a wife and 7 kids from 8 years old to 23. The roads here suck, and I don’t see driving + texting going away anytime soon. So it’s time to sell unfortunately.

Dan

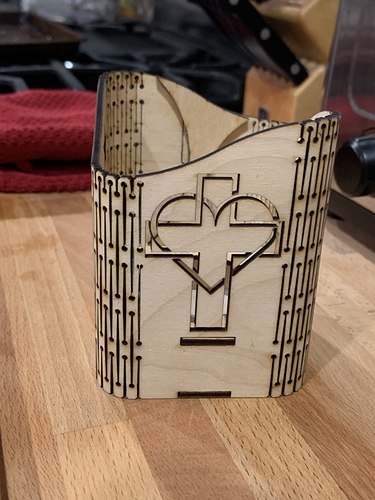

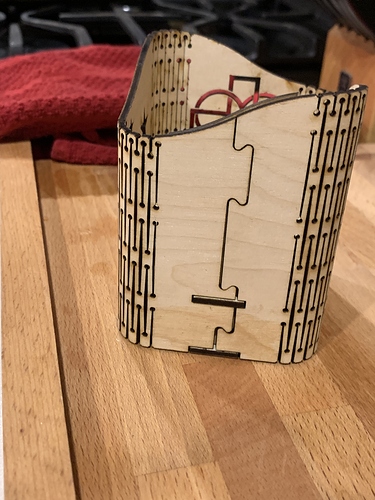

Results now that I’m up and running. 10mm/second (a little over 23in/min), single pass, 3mm ply. Total cut/engrave time a little under 14 minutes, no Xacto cleanup needed. Not my LaserOKO, 50 watt CO2 laser:

Dan

@DanoInTx, that looks pretty clean - how are you finding it in comparison to the JTech? Has it satisfied your expectations / hopes / dreams / upgrade-itis?

It’s fast, very fast in comparison. I still only have 12”x20” of work area and kinda wished I’d spent a couple more $ on a 60 or 80 watt with a larger area, but overall it’s doing everything I ask. The JTech is a nice piece of kit though and I’ll still likely use it for larger engraves. But 14 minutes versus 3 hours to cut the same parts is pretty cool!

Dan

@DanoInTx - would you mind showing us a picture of your shiny new setup? I’d be interested to see how it compares.

At my day job currently, but here’s some pictures from my phone when I first got it running. I’ll try to take some more tonight and maybe a little video:

Dan

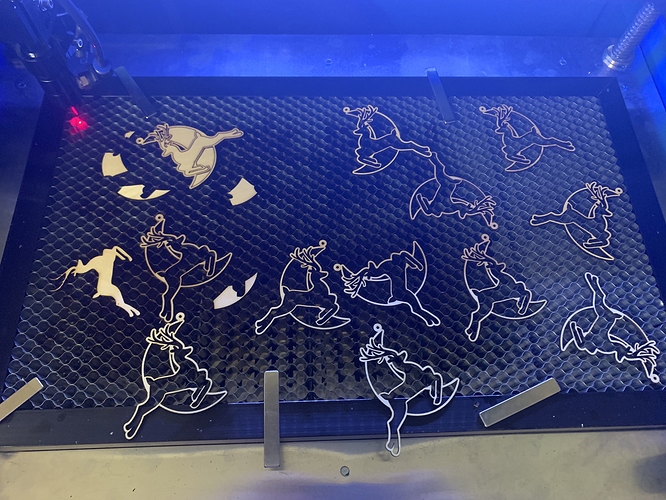

Reindeer Season, getting some parts made for Christmas Art in the Park:

And a little video of my setup. This is cutting 3mm Baltic birch plywood one pass at 11mm/second:

Dan

50 watt CO2 300x500 bed with Ruida controller. It’s from Orion Motor Tech (US shipped, Chinese origin). I bought from EBay which is a few hundred $$ less than same on Amazon. It came with a small air assist compressor, I had a better one. It came with an aquarium pump for cooling, which would never work in North Texas summer, so I bought a CW-5000 chiller (tube temp should be around 18-20C, water in a bucket isn’t gonna work here). The stock 800mm tubes are really overrated 35-40 watt tubes, so I added a 1000mm SPT tube and a 60 watt power supply from LightObject. I added new mirrors all around and a 50.8 mm focal length lens, also from LightObject. Tube output max tested is 53 watts at 18mA, I run it at 16 max for tube life. So at this point I’m probably $3k into it, but it cuts everything I need it to plenty fast so I think it was worth it. It’s a bit of a “kit” in that it took a little tinkering to get just right, but it functioned ok out of the box. To do it all over again I would do it the same except I’d probably shoot for a larger bed, so probably a 60 or 80 watt machine, but only for the bed size those machines come in, the power I’ve got is fine for me. Let me know if you have anymore questions.

Dan

This topic was automatically closed 29 days after the last reply. New replies are no longer allowed.