Looking to replace the wasteboard on our Shapeoko 3xxl. What are the recommendations?

Buy a chunk of MDF from a home center (if need be, have it cut to size — if you trust them to make accurate cuts), take home, pull current baseplate, clamp together, use the existing baseplate as a template to cut the new one.

For notes on dimensions see:

Thank you. Is there any upgrade setups with more hold down options?

I have an SO3 XXL. I use a threaded spoilboard with 1/4-20 tee nuts. I also use cam clamps to secure my work. I purposely make my spoilboard small enough so the entire surface can be surfaced and not leave a ridge at the back and/or sides. I will include my .c2d file for making a threaded spoilboard.

I almost always use bottom of material and hardly ever cut into my spoilboard. It is a change of habit at first bit it works well for me.

optomized_spoilboard_v7_cc_03162025.c2d (628 KB)

Additionally I use a long L clamp which stays on my spoilboard most of the time. Inside the file are also some cam clamps.

long_L_bracket.c2d (296 KB)

Here is my rationale for making an optomized spoilboard for my SO3 XXL.

spoilboard_considerations.pdf (1.3 MB)

See:

and

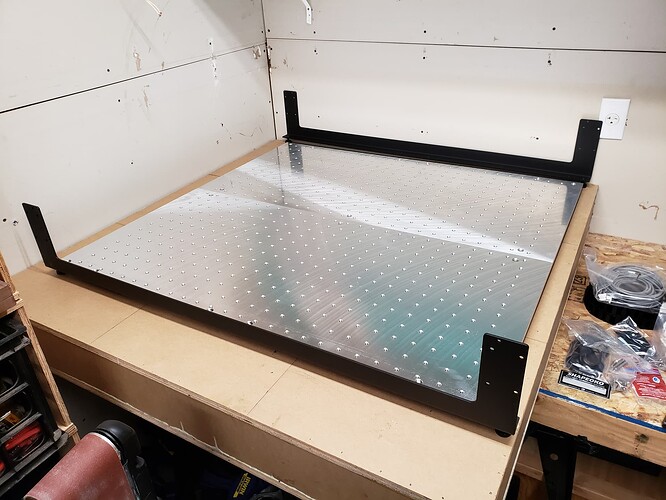

I went totally overboard with a 1/2" aluminum plate with 1/4-20 threaded holes every 1.50" from Ohio Diesel Parts. It normally comes drilled and tapped for 5/16-18 fasteners, but I already had a whole setup with 18-8 stainless 1/4-20 SHCS from 0.75in to 4.5in in 1/4" increments, so they made mine with 1/4-20 threaded holes.

For larger things, I use the Incra Build-It clamps but I tossed their long T-bolt and knob and use the SHCS.

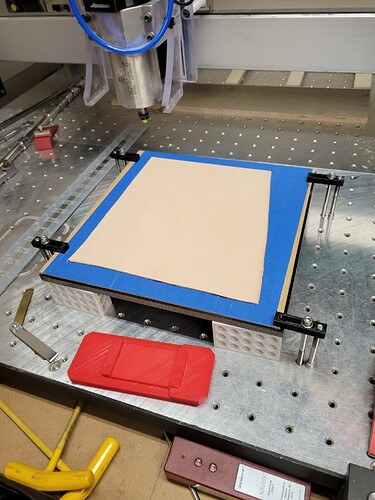

For smaller things, I use Thorlabs CL-5A clamps. You can get them one at a time or 5 packs. I have ~10 or 15 of them, I can’t remember.

And for some other things, I use Thorlabs CL-3 clamps. These come threaded 1/4-20 (CL-3) or M6x1.0 (CL-3/M). They are nice because you can use them directly on the bed, or use a set of screws to clamp something really tall. The pic below was to show the height I could clamp if needed. The support screw (on the right, with the head down) is 1/2" shorter than the one on the left that provides the clamping force.

I also 3D printed some 1-2-3 blocks until I could buy enough metal ones. I bought really cheap ones, since I am mostly doing wood, and the 0.001" they are off is fine for now.

Here are all of the Thorlabs table clamps if anyone is interested.

Thank you everyone. These are all great.

Wow that is a cool setup. You spent some time designing and implementing that setup. ![]()

Thanks! Yeah, it was an evolution of baby steps to get where I am now. I had a pre-order SO3 with the original flat Z-axis router mounting plate that was pretty flexible, and the DeWalt router.

Then I upgraded to the more rigid Z-axis mounting plate when that was offered, and that helped a lot.

Then I put in 1/4-20 threaded inserts in my MFD wasteboard and bought a bunch of the Incra clamps and SHCS.

Then I bought the SuperPID speed controller for the router, and that was awesome to be able to run at slower RPMs for some material, and have it automatically keep the RPMs stable when cutting.

Then the SO3 XXL was announced, and I started planning. I planned on using some T-slot plates from Misumi (HFSQN4-15250) and fasten them to the original MDF wasteboard.

Then someone posted that ODP was making those threaded plates, so I jumped on it.

I figured I was going to go all-in on this one, so I bought the original Beaver HDZ and an 80mm 1.5KW ER-11 spindle as well as the Suck-It dust shoe with the 2-1/2" hose attachment.

That was not big enough, so I used the mounting hardware, and designed a new shoe that used a 4" hose to get more airflow through the shoe and catch more wood chips and dust. I should re-design it and add a bit more clearance for the 80mm spindle, and make the hole in the shield a bit bigger.

The other clamps just kind of happened when I would need a smaller clamp, and just couldn’t see spending $$$ for the Mitee-Bite products. Not to say they are not worth their cost, but for me cutting 90% wood, there were other options for less money that served my purpose just fine.

This topic was automatically closed after 30 days. New replies are no longer allowed.