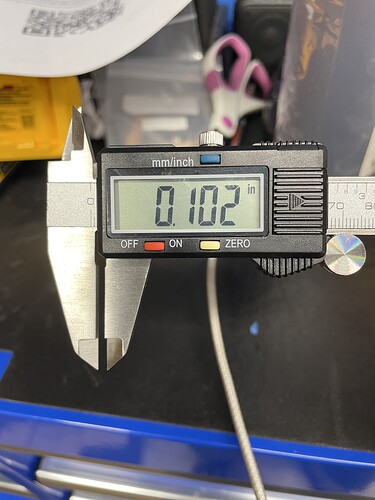

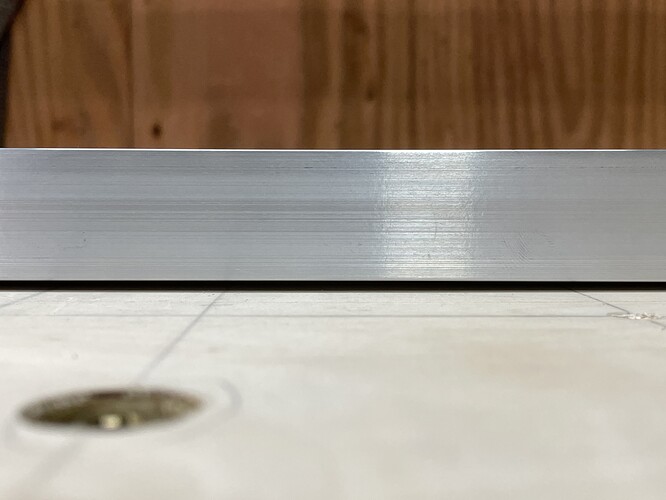

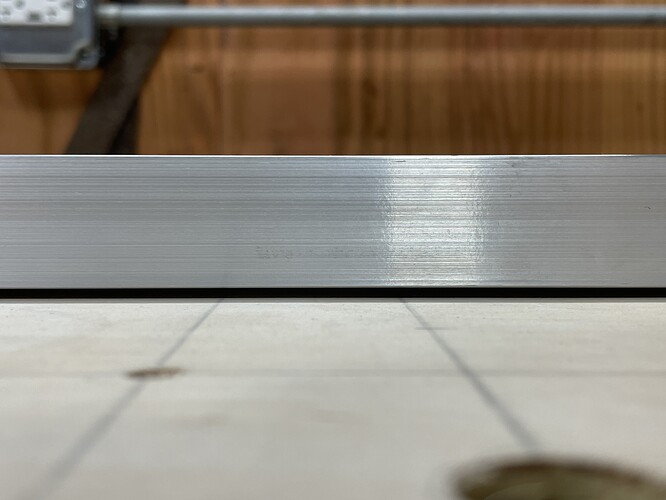

Ok so as the title says I need help in regards to the table I built for my machine. I am wondering if I need to redo it because I am getting quite a bit of flex in the mounting rails. I have measured the gaps between my table top and the bottom of the rails to be about .102 and .108. And I am unsure about shimming it to take the flex out of the rails. I’m up for taking any suggestions on what I should do to rectify this. I have posted a number of pictures below that show what I am dealing with.

Your wood table is likely not perfectly flat. I think the general suggestion is putting some dense rubber mat, or maybe some extruded polystyrene sheets (might be a static issue tho) under it, to evenly support it. Once you tram your surface you will have a flat working surface.

I used Harbor Freight Anti-Fatigue Mat sections under my SO5 Pro:

https://www.harborfreight.com/4-piece-anti-fatigue-foam-mat-set-94635.html

takes up the unevenness of the wooden table surface and dampens noise and vibration.

Thank you very much for the advice. I found a full package of Matt squares like the harbor freight

Ones and I will use them tomorrow. Hope this works and I can get my machine up and running tomorrow.

Any concerns about the mats compressing more in the area where the gantry normally rests and then having that lead to an uneven surface?

I bought some but have not put them under my Pro yet as I wasn’t sure if the hybrid tables really benefitted from them.

Not that I’ve seen — the mats compress and take up irregularities from both the underside of the machine and the surface of the table.

What seems to be working for me → I picked up a VersaTex 36" x 60" recycled rubber floor mat (Item# 9M-110-36C-5) for my SO5 2x4 table from Amazon for relatively cheap. Doesn’t compress much at all, but seems to buffer well.

To this, I anchored my squared 2x4 table through the mat to my table. No movement - locked in.

Interesting. So you you bolted the 5 Pro to the table through the mat.

Yep. Have 3x Home Depot Husky 62" tables interlocked in a U shape, with the SO5 taking one of them. Near zero movement no matter how hard I jog the unit. In my case, I was concerned that rear of 2x4 bed overhung the table by 1" - so bolt down gave me peace of mind to negate any chance of shifting.

Another thing I did was Loctite blue all bolts except the waste board center bolts. Seems prudent given the inherent vibrations involved in fabrication…

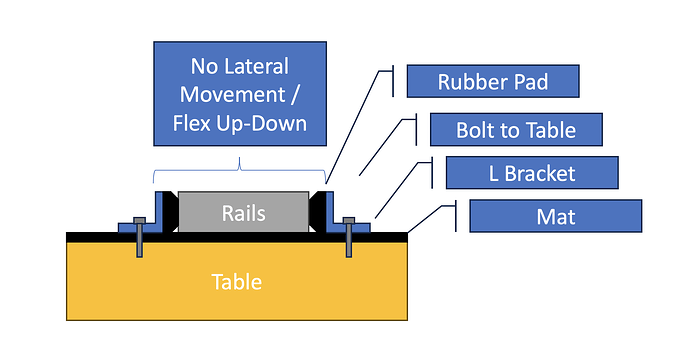

Please note that the official recommendation here is to not fasten the machine to anything, unless one knows that it is flatter than the machine structure — if you’re concerned about movement, block it in from the sides w/ some suitably padded blocks or angles.

Secured using L brackets with rubber blocks to prevent lateral movement. Should have been clear there…

You are defeating the purpose of the rubber by bolting the machine down.

Let me clarify further with a picture…

Arguably the same could be achieved with drilled holes and rubber gaskets, but I didn’t want to void warranty by drilling rails…

I see, the machine is not actually bolted to the table.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.