So I picked up some keyhole bits I’d like to use on the backs of some of my work to hang on the wall. Was hoping someone more versed in gcode than I could help me out. Basically I want a program to drop z say -.25”, then run y .75”, then back y out to starting position and z up. Seems simple but I haven’t tried doing any gcode editing or programing yet on this machine. Can someone lend a hand? Thank you

I would like to say that you should run a straight bit first to clear the path, then switch to the keyhole bit.

Check out this video by Mark Lindsay. It explains very clearly what you need to do to set up a keyhole tool path. While you’re there, subscribe because he has EXCELLENT videos. He does Vectric products but a lot of his information is applicable to other software.

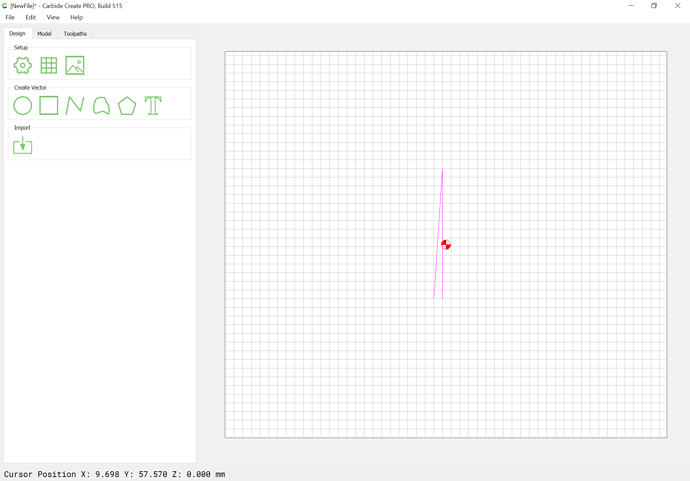

Simplest way to do this is to create a 3-node polyline:

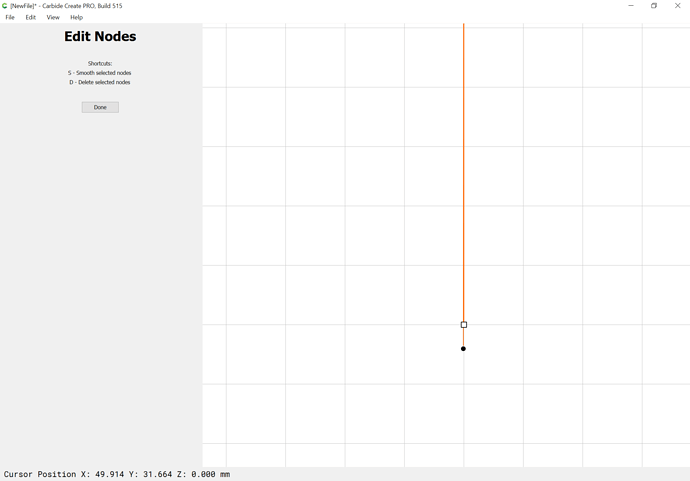

Then drag the two bottom nodes to be in-line:

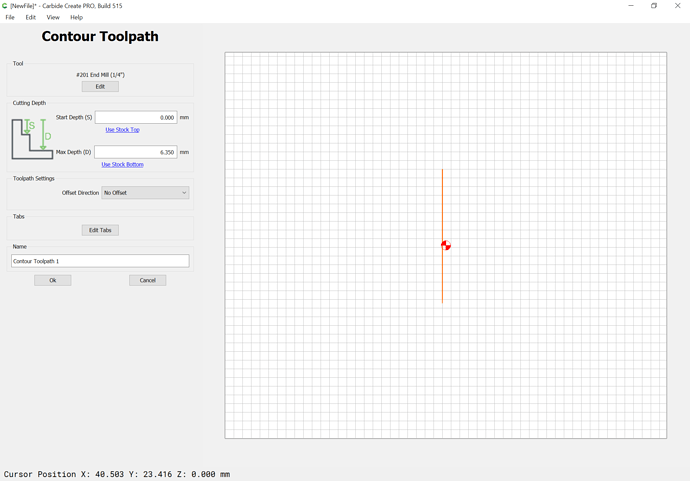

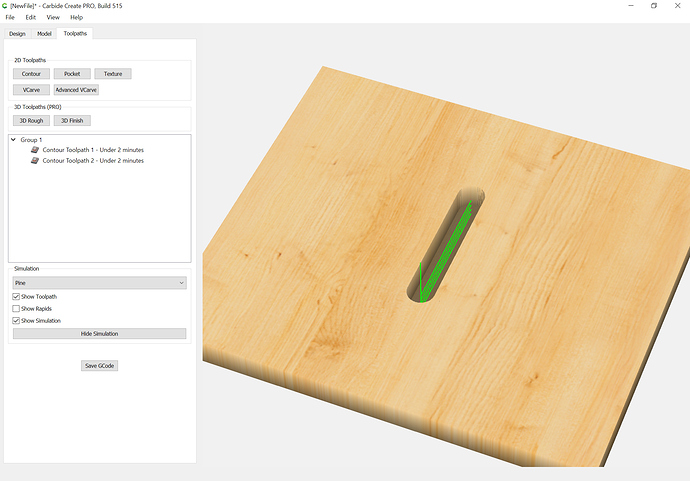

Then assign a pair of no offset contour toolpaths to the appropriate depth:

First one should be with a square endmill the same width as the shaft of the keyhole bit, second should be using the keyhole endmill and should have a depth per pass deep enough to make the cut in a single pass:

This was handwritten and untested, but I’d try it this way.

Send your endmill at the location of the hole and the gcode uses a G92 to temporarily set that as your XYZ zero. I guess you could just use relative mode as well.

Also, do you have a source for a “low profile” keyhole bit. Most I’ve seen and used have a 3/8" or 1/4" head. You’d probably want to plunge deeper than 1/4".

G90 G94

G20

G92X0Y0Z0 ;temporarily set current location as XYZ zero

G0Z0.2

M3S16000

G4P0.25

G1Z-0.100F20.0

G0Z0.1

G1Z-0.200F20.0

G0Z0.1

G1Z-0.25F20.0

G0Z0.1

G1Z-0.25F20.0

G1Y0.25F60.0

Y0

Y0.5

Y0

Y0.75

Y0

Y1

Y0

G0Z0.2

M30This topic was automatically closed after 30 days. New replies are no longer allowed.