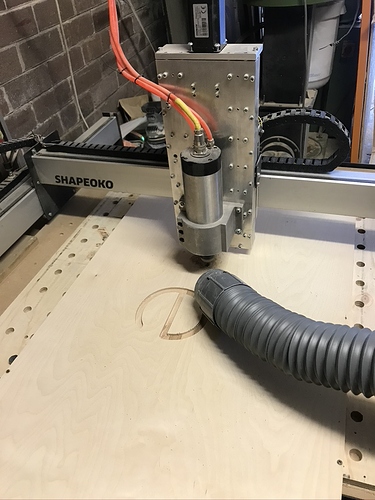

I have an XXL with a Chinese 2.2KW water-cooled spindle with ER20 collets. I have built a new Z-axis for it because the stock one was woefully inadequate. (nursed the stock Z-axis along so I could cut the parts for the new Z.)

The new Z-axis if fantastic! I no-longer worry about tool paths that need to raise and lower the bit repeatedly. I upgraded the steppers on Z and X to ones with more torque. Definitely recommended… I ordered linear rails for the X-axis too. Should be another big step forward in reliability like the Z-axis has been. (after I ordered them I saw Shapeoko have gone down this path for the pro model too.) I find the ER20 very useful. A lot of my tooling is half inch. It just feels more solid to me. I recently printed a drag-knife for cutting cardboard using my Shapeoko; the 1/2" shaft butting against the shoulder of the ER20 collet is study enough for cutting even quite thick cardboard. It would not have been remotely possible with a smaller collet.

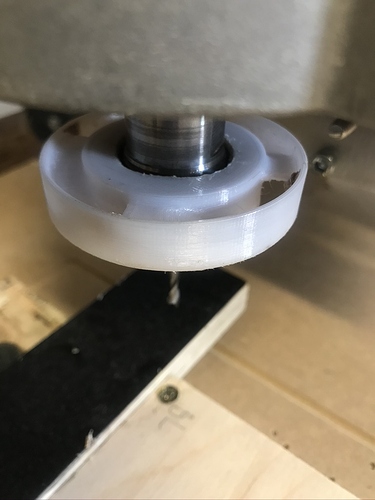

The other upgrade I heartily recommend is a small 3d printed fan attached to the spindle. It blasts a hurricane of air down the cutter into the trench the cutter has just made. It blows the swarf out so well. It’s made my machine much more reliable, especially when I use down-cut or compression bits.