I’m new to cnc and just purchased my first machine. I purchased a Shapeoko XXL. I got in used from a local guy that was moving and could not take it with him. I have completed a couple of test projects and I’m quickly learning . I do have one problem with the machine. I cannot get the toolhead to move all of the way forward and to the front left. I have tried the “rapid jog” feature and the “manual jog” feature. When I try to jog it to the front left it only goes to the center middle. I have just positioned my project in the back right for now and it works fine. I have loaded projects using the settings for both Shapeoko 3 and Shapeoko XXL with the same results.

I feel like I’m missing a setting or something that is causing this to happen. Any help would be appreciated.

In the software, be sure to set it to Shapeoko XXL - you’re getting the dimensions for the small machine.

Thanks Mike. I tried that. I tired it set on XXL and 3 with the same results.

Just double-checking the obvious, no offense : you did click on “Send config data” after setting “Shapeoko3 XXL” in the Setup sub-menu, right ?

Can you try re-sending the XXL config, then “Open Log”, go the MDI console, type “$$”, and copy/paste here the list of $xxx parameters being displayed ?

Julien thank you for your reply. In the job setup menu I have the option of Ok and Cancel, if Im looking in the right place. I do not see “send config data”. If I’m not looking in the right place can you let me know where to find the correct menu.

The send configuration is in Carbide Motion: https://docs.carbide3d.com/support/carbideupdater/#carbide-motion-v4

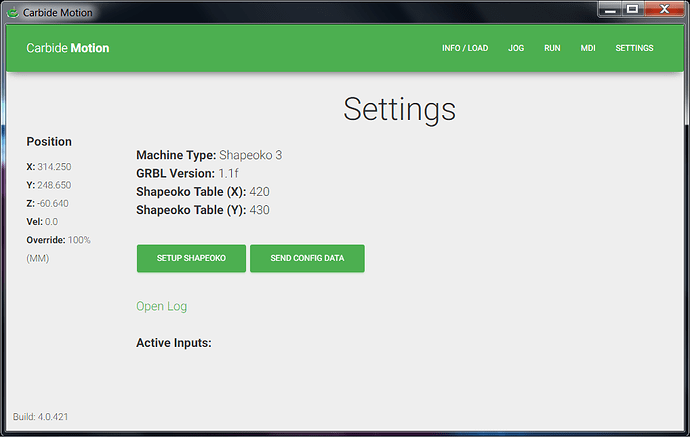

Oh, I think you were referring to Carbide Create “Shapeoko” settings, actually what Mike was mentioning is the Carbide Motion “Settings” page:

That’s where you need to select Shapeoko3 XXL and do Send Config Data

Yep that is probably my issue. I will go in tonight and set it up. Thank you guys for your help. Ill let you know it it works. Thanks again.

Thank you guys for the help. It fixed the problem. Being new I’m sure I’ll need a lot more help.

New or old we all need help! Welcome.

I recently bought some Stls for my machine and I can’t even figure out how to change them all for my machine to make it work.

I’m a hands on individual who learns from seeing and doing it. Your tutorials move to fast for my brain to grasp it!

Not saying that I am illiterate but, I am not the brightest bulb in the world either!

STLs are stereolithography files — 3D triangular meshes which represent 3D shapes — they’re not really editable (though you can load them into for example Microsoft 3D Builder and modify them to some extent).

You’ll need a 3rd party 3D CAM tool which will import STLs to make them into G-Code — options include:

- MeshCAM from http://www.grzsoftware.com/

- Freemill

- pyCAM

The former is the easiest, but is an additional purchase.

I would suggest starting with “Design and Make” — there are a number of free 3D models and that will at least get you started. I did a basic tutorial on this at:

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.