Removing that much wood just takes time. I looked at my settings just to see if a 1/4 bit with a much higher depth per pass would be faster (it was not). So the McFly is your best way to do this, but there is still hope to speed things up.

My thoughts if I was doing this…

(1) Carbide Motion has a feature that lets you adjust the feed rate (10% to 200%). You can use that feature along with what your ears and eyes are telling you to change the feed rate as needed. I would suggest starting with a slightly more aggressive feed rate of 80ipm, and when the job starts use Carbide Motion to (initially) decrease the feed rate to 50% so you’ll start at a VERY consertive speed of 40ipm. But your effective range of speed could be from 8ipm all the way up to 160ipm.

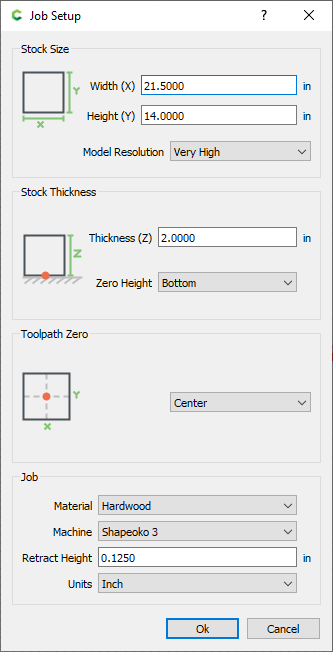

(2) In Carbide Create I would set the Zero Height to be “Bottom”, since the ending thickness is your most important stat. Experience tells me that the reality is that wood is not (exactly) 2" thick, and doing this makes up for whatever variation there is.

(3) However, because of my “Bottom” setting I would know that the very first pass will NOT be taking off exactly .02 of material, could be more, could be less. So while I would be adjusting the speed during that first pass, I would know that the 2nd pass would need it’s own adjustments as it will be taking off exactly .02 inches. The tuning during that 2nd pass should be the same for the remaining 38 passes.

(4) Dust collection, you are about to make a lot of dust. Keep on eye on everything, and use the “Pause” feature in Carbide Motion if you need to. I use it that when something looks off and I want time to think, evaluate, clean up, etc.

(5) Work Holding, very important. I would use a lot of clamps, I would make sure they all stay under 1.225 inches from the bottom of my material. The wood is going to change on your during this operation, whatever internal stresses there are in the wood are going to change, removing that much material I would just expect it to warp a little (or a lot). I would NOT trust double-sided tape to hold that material for that long under these conditions.

(6) Don’t hesitate if you instincts are telling you to hit the kill switch. This job is very easy to start over after remeasuring the (new) thickness and altering the stock thickness in Carbide Motion. You may even want to kill the job and flip the wood over to mill off the other side, depending on which side starts to warp.