Never one to turn down an offer for advice

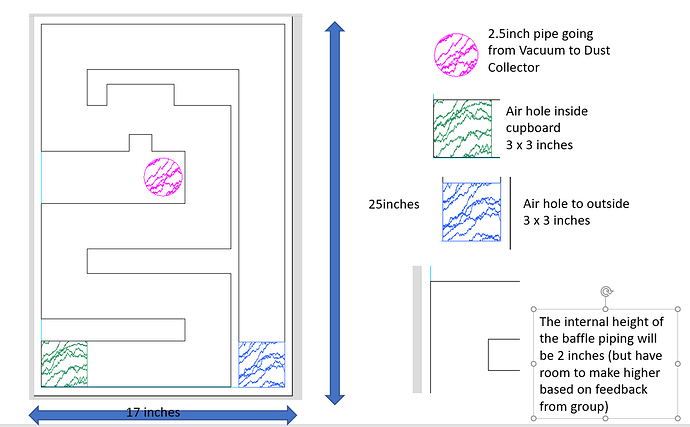

I’ve uploaded the baffle for the vacuum cleaner cupboard. It is going to go against the back wall of the cupboard as I have depth, but not height.

I altered the airflow intake to be a 3inch x 3 inch entry point, and made sure to keep the width of the tunnel 3 inches throughout the maze. In terms of height, I was hoping to get away with just 2 inches, but can make it higher if need be.

I realize it is not the sexist baffle design, but was hoping that with enough turns and length, a lot of the sound would be lost