Linky:

Very nice! I tried to send you a tip over there, but noticed you weren’t set up for that.

I never remember to. ![]()

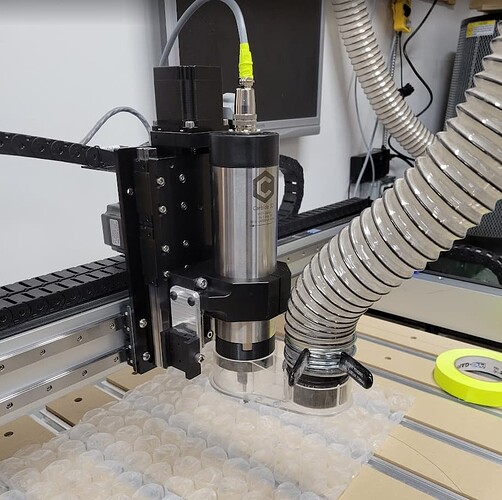

Alright I got my spindle in this weekend.

The Sweepy is definitely an issue. Anything longer then the shortest of bits won’t get coverage by the sweepy. I hope C3D releases an updated Sweepy down the road, possibly with a discount to spindle users.

That said, I’m printing this adapter now to help out. Hopefully it stays put, or maybe I can tape it in place.

Otherwise the spindle is great, C3D sorted out some QC issues and sent me a new one. I removed the 0.2mm shim I had in place on my mount before with the Makita trim router and I’m now within 1 thou front to back and side to side. (No shims, just spindle straight into the 65mm mount)

If you’re talking about mine, it doesn’t inherently stay in place… at least off my resin printer. The clamping force of the Sweepy keeps it in place.

Ah ok, that’s going to make adjusting it a bit less straightforward than hoped. Hopefully an interim measure.

FDM printer and it will stay in place on it’s own! Big bonus. Perhaps it will get loose over time. I might reprint in ABS, I’ll see if the spindle stays cool to the touch during long machining jobs. If it warms up I’d worry about PLA becoming a bit soft.

Nice! My spindle doesn’t get much over ambient.

C3d has a new sweepy for the hdm.

It says only for hdm but design might be adapted to other models. The $150.00 price would encourage home grown versions.

What type of clamp do you have on the flex vac hose. (black handle, squeeze type). Where did you get it ?

thanks

Got em at BusyBee tools which is Canadian, but I imagine they are everywhere?

Various options available at Woodcraft and other woodworking shops:

I purchased this same style clamps at my local Woodcraft and on Amazon.

Well done all making the adaptors. I do have an 80mm Sweepy in the shop as I was originally planning on going the route of an 80mm spindle so I think I’ll do something similar but instead I’ll expand on the 65mm of the Carbide spindle and go up to the 80mm size instead.

Another adapter inspired by those above and plenty of air passing through it

(Edit: Adding the .stl file if anyone is interested. The one I got printed by a friend fit really tight so I had to sand down the edges of the thread/rib pattern on the inner diameter against the spindle body. Therefore in the model attached here I opened it up a bit to 49mm so it should still be quiet snug so adjust as you like/need to or leave as is and sand down as needed to get perfect fit)

C3D 65mm Spindle Sweepy Adapter.stl (498.6 KB)

Good tight friction fit, used a C clamp and worked my way around lifting just a bit at a time until all the way up.

Now I’ll see how it holds up over time.

That looks really good Patrick. I did end up printing Josh Tenny’s out of PETG. I imagine yours is just as rock solid as his. I did buy a 4" hose plate from Kent CNC because my ultimate goal is to have my 4" dust hose connection directly at the spindle.

But these are solid designs that work great. The friction fit of his design is perfect; and I’m sure yours is too!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.