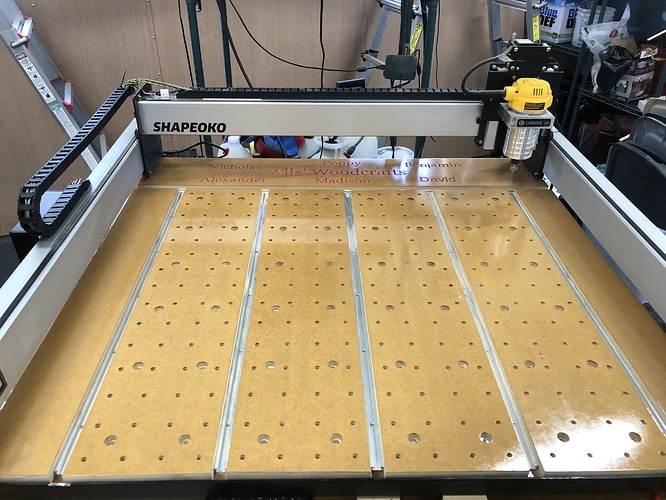

Attached is a picture of my new waste board for my XXL. I wanted to have the options of both T-track and the use of screw downs.

Nice. I did a similar thing with mine (just reworked the T-track mounting system, now using M4 rivet nuts from the underside of my HDPE baseboard). The waste plates on mine are made of that plastic composite deck board (after some flattening and planing), but the same concept of T-track and threaded fixturing.

If you like yours as much as I like mine, you’re in for a treat.

Thank you for the reply. I ended up with the MDF because I’ve been reading about the synthetics/composites warping/cupping to much. Will be interested how your’s works out. I’ve already used it when I did my first V-Carve for the board at the back of the machine and it worked great. It definitely beats having to use tape and super glue all the time. I am waiting on my Suckit shipment before doing to much more. I am already tired of all the dust that gets created. It doesn’t help my breathing even with a dual filter mask because of all the dust still suspended in the air. We want even discuss all over the shop.

MDF is certainly the standard, but for me, personally, I wanted an MDF-free baseboard/wasteboard setup due to the excessive amounts of moisture in the air here in Baton Rouge. Everything seems quite dimensionally stable so far. If I were planning to do heavy cuts in aluminum or something, I’d likely add some features below the wasteboard to help take the load and minimize deflection, but that’s not something that I’ve needed to worry about at this point.

As for the Suckit, it does indeed make a world of difference. I got a Dust Deputy (or there’s also the Dustopper at Home Depot) to collect most of the dust in a bucket before it gets to the vac, and I even ended up installing a dryer exhaust style wall thimble so I can exhaust the vac outside. (That eliminated any super-fine particulates and smells inside my shop area, and it came in really handy once I added a laser to my machine and made a custom SmokeSucker that slides in to the Suckit arms.)

It’s been very wet here for the last 8 months or more and I do have some issue but after today that should be near 0. Had a new mini-split Air Pump installed today and it raised the temp 10 degrees in 10 minutes. It also. Has a Dry setting so it can be used a dehumidifier when heat or cooling is not needed. I am interested in hearing how well your waste boards work over time. Are there any voids/chip outs in the composite boards on milling down. The ones I’ve worked with in the past from the local big box stores seem to have this issue when cross cutting or ripping and concerns me on milling flat and my thought is that with melted residue left on saw blades when cross cutting/ripping, that it would it leave a lot more on the milling bit. Have you had any of these issues yet?