Does anyone have a starting point for the Amana 45783 18 degree v-bit? I am trying to get a little more detail on a project that I am doing. Tried using a 1/32" 6.2 degree tapered ball end mill for the detail and it was a little to much at a DOC 0.03". Thanks in advance.

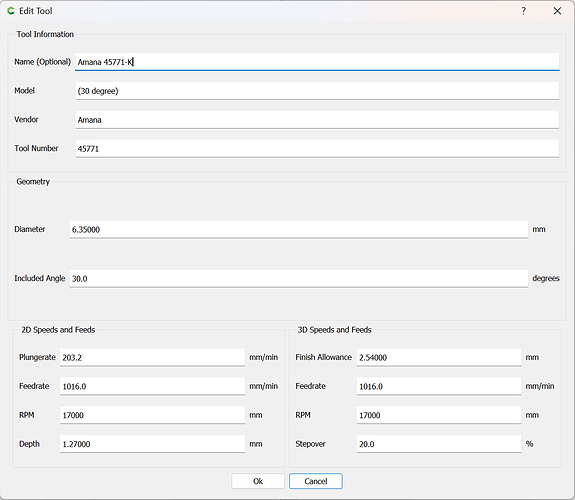

I entered a similar 30 degree tool as:

but while I bought a similarly very acute V endmill from Amana, I haven’t used it for anything other than pricking holes in leather (in conjunction w/ a drag knife).

Thank you for the help. I will try this out and see what happens. The other bit did really well on everything but the inside detail of the badge. Also, do you think that trying this in oak would give a better finish that in pine?

Depends on the grain, toolpaths, and feeds and speeds.

Thanks for the info.

Pine is not the best choice for fine detail.

I prefer hardwood. My favorite for fine detail is Walnut.

If you want white wood, try Poplar. I have had success with Poplar vs Pine.

Another quick tip is to check the Tips of all Fine V-bits. I had one fall out of the Collet, and the fine point broke off. I effectively made it into a very small EM.

If you go with hardwood, like Poplar, getting a 1.5" thick piece will be pretty expensive.

I suggest using two parts of stock that are .75" thick.

Carve the bottom piece details and then do a contour cut.

Reload a new piece of stock, carve out the “Wall” piece, and glue them together.

.

Top of Badge.c2d (608 KB)

Bottom of Badge with Details for _75 stock.c2d (1.7 MB)

I bought a 15 degree vee bit from Amazon. Here are the custom tool database for that bit.

| number | vendor | model | URL | name | type | diameter | cornerradius | flutelength | shaftdiameter | angle | numflutes | stickout | coating | metric | notes | machine | material | plungerate | feedrate | rpm | depth | cutpower | finishallowance | 3dstepover | 3dfeedrate | 3drpm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 703 | Foos | 703 | 703 15 degree vee | vee | 0.25 | 0 | 0.5 | 0 | 15 | 2 | 1.5 | 0 | 8 | 14 | 18000 | 0.05 | 0 | 10 | 14 | 18000 | ||||||

| 704 | Foos | 704 20 Degree Vee | vee | 0.25 | 0 | 0.5 | 0 | 20 | 2 | 1.5 | 0 | 8 | 10 | 18000 | 0.05 | 0 | 10 | 10 | 18000 |

I only use those for thin lines in vcarving. A 60 or 90 degree vee bit barely scratches the surface for really fine lines.

I have thought about doing this in two pieces. I don’t have a problem with getting the stock in 1.5" or in .75" for the cuts, the problem that I have is that the bit was removing to much of the fine detail in the center of the badge with the small size of the text. I am going to try it with a piece of poplar that I have here and see what it does. I also have some oak and cherry that I am gonna try and see what happens. Thank you for the help

Thank you for the info, I will see what happens with the feeds and speeds you sent to me

This topic was automatically closed after 30 days. New replies are no longer allowed.