Hello everyone,

I am only a couple of weeks in, so be gentle. I searched and read almost everything here in the community trying to figure out what my issue is before finally breaking down to ask for help outright.

My issue: when attempting to use the Advanced VCarve feature in CC to create a somewhat intricate design in a piece of maple, I am getting disastrous results. The detail and perfection that I see in the Simulation is not translating to the work. Way too deep, the cuts themselves are way too wide and end up giving me a what looks like a chewed up dog toy instead of the intended result. To me it is obvious that I have a depth of cut issue (given the V geometry of the end mill itself, the deeper it penetrates, the wider the cut will be).

Here are my settings and everything that I can think of that would be relevant. Happy to provide any files, pictures, etc. beyond what is here.

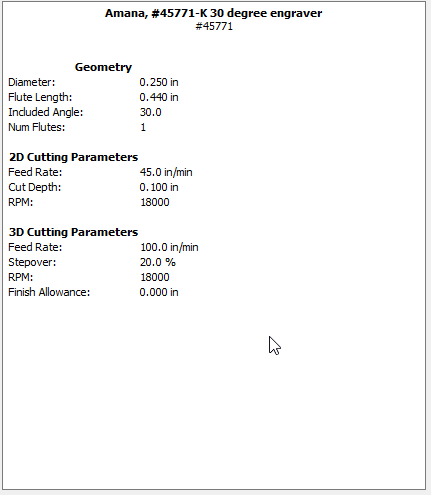

End Mill: Amana #45771-K 30 Degree Engraving 0.005 Tip

Material: .5 inch maple

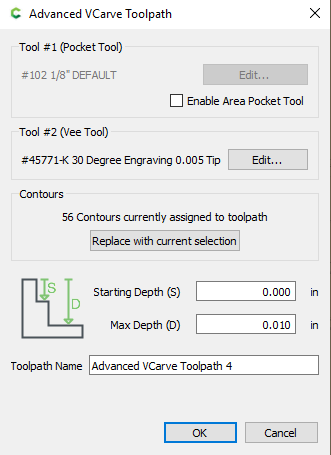

Settings in Advanced VCarve:

Starting Depth: 0.000

Max Depth: 0.010 (I know it is super shallow; this is a small piece)

I am using my Bit Zero to set my Z height, and have done this successfully with other jobs. Regardless of what Max Depth I am choosing in Advanced VCarve, I am consistently getting a depth of cut of greater than .12 inches (as measured with a caliper). At first I thought maybe I had chipped off the tip of the end mill, resulting in a wider cut…but even if the lines were wider because of that, I would expect them to only be as deep as the Max Depth setting.

I ran the job 3 different times, adjusting the Max Depth setting in Advanced VCarve each time, only to have essentially the same result: anywhere from .12-.13 deep engravings.

What else should I start checking? The greatest thing for me would be that someone points out I am doing something totally wrong…those are the easiest fixes.

Edit: Looks like I can only post one image at a time. I will start with what the Simulation looks like, and hopefully follow up on a reply with the rest of the images.

I appreciate your attention to detail.

I appreciate your attention to detail.