Just wondering if we can get a small repository of sorts going for people to share their recipes, with a focus on maximum MRR.

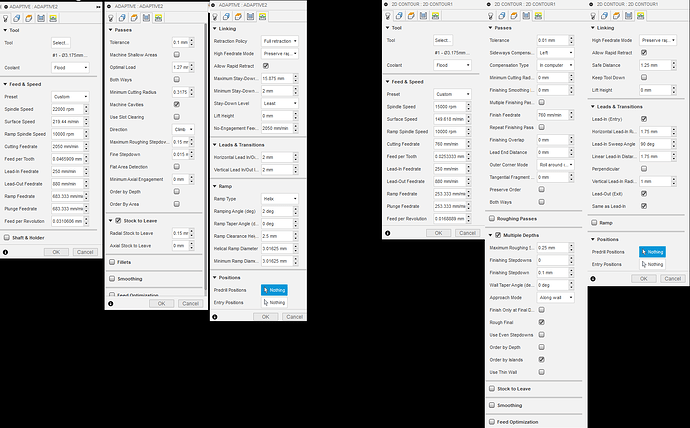

With some help from provencut, I’ve been using a high WOC/(very) low DOC recipe with Datron 6mm single flute endmills: 0.25mm DOC, 5.3mm WOC, 2200 mm/min for a MRR of about 3.5 cm^3 per minute in 7075-T6. I run it a little harder when milling 6082, going about 2500 mm/min. Even at 170% override, these settings don’t stall the spindle though you can clearly hear that the machine isn’t happy and the steppers can start skipping steps. So I know 2200mm/min is reliable. Using these settings, the Nomad roughs out the little roughly 85mm diameter/17mm thickness stock that I use for the airgun mags I make in about 1.5 hours of spindle time, with good chips forming and no chatter (using Fusion 360).

However, I’m wondering if I can get better MRR by going low WOC/high DOC on, say, the standard 1/8 inch #102 endmill. I’ve tried that in the past but couldn’t find a recipe that didn’t create a massive amount of chatter and noise, so I figured the Nomad 3 just didn’t have the rigidity to get it done and settled on the above recipe.

What have your experiences been using deeper cutting adaptive strategies on the Nomad?