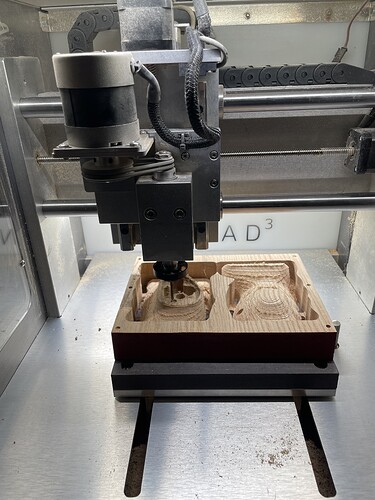

Hi there! I have had my Nomad 3 for 3 years now, with no issues other than the door hinge breaking a couple of times. I’m a hobbyist and I don’t really put it to that much use. Making mostly small objects in wood and plastic, inlays in wood and some small components in metal. Everything always has worked out pretty well. And I always vacuum after each operation and apply Super Lube every now and then.

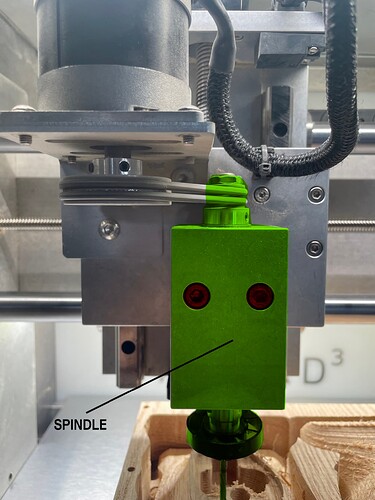

Unfortunately, after machining some Delrin not so long ago for a prototype of a camera cage (that ultimately will be done in aluminum), a chunk of Delrin most likely flew and fell behind the spindle, where the Z axis is. There were lots of Delrin pieces flying everywhere so it must have been that. The machine started doing a loud clacking noise and got stuck. I stopped it before it got worse and immediately put some Super Lube. After re initiating the machine, the noise was almost gone and everything went back to normal. But I could still feel that there was something in there when the spindle would travel between a certain range in the Z axis. But it was minor enough that I did not do anything else.

Unfortunately the noise has been getting worse over the last few weeks and adding Super Lube is not working anymore. Up to a point that today it got completely jammed and I received this error:

HM009: The machine could not find the homing switches.

This could be caused by:

- Mechanical problems jamming a machine axis

- A malfunctioning homing switch

This is equivalent to GRBL Alarm 9.

https://qr.carbide3d.com/error/hm009

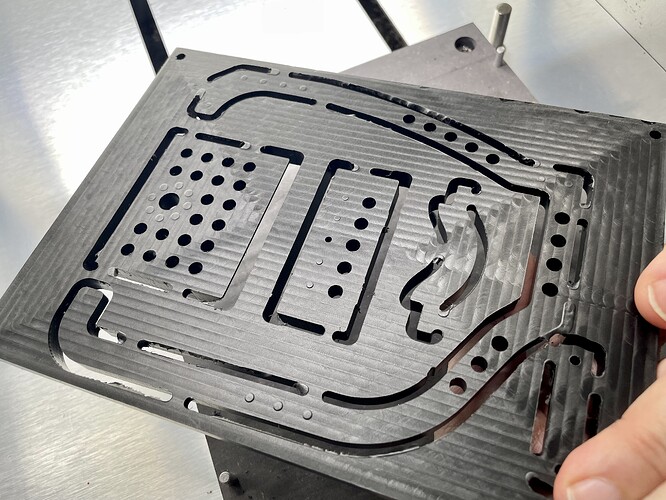

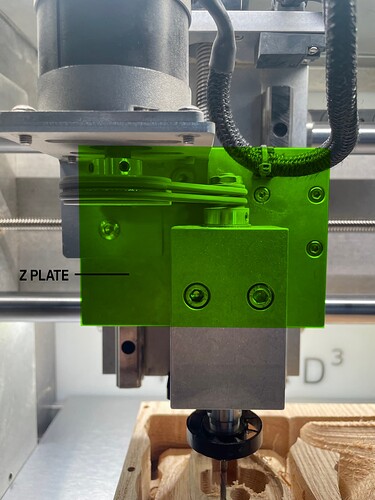

I tried taking a picture of the affected area but it’s really hard to get the phone in there. Regardless, you can still see that there’s some wood and Delrin particles in there:

Before this happened, the machine had been running for a couple of hours doing a 3d adaptive operation for a wood handle. So maybe it built up a lot of stuff in there.

I’m really bummed, I love this CNC and the fact that something got really messed up terrifies me. I’m hopeful in thinking that the construction is so robust that once I clear out whatever is jamming it’ll be as if nothing happened.

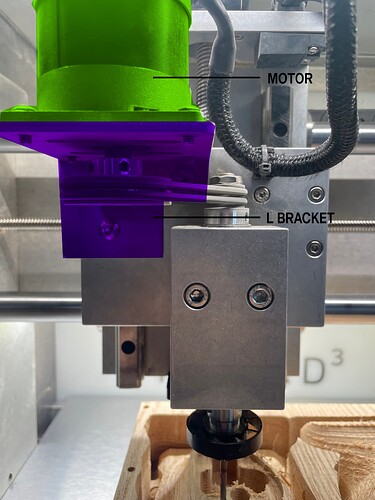

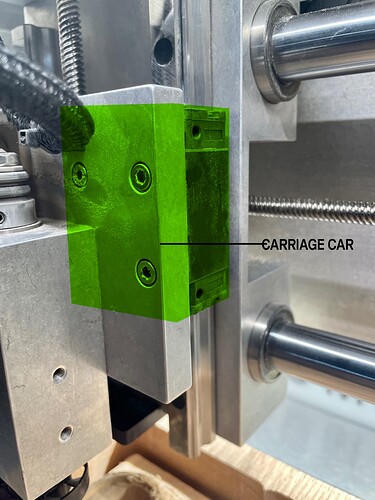

Is there a way to safely disassemble some parts of the machine so I can access the Z rail and troubleshoot the area?

Or is there a specific procedure I can try to get it unstuck?

I reached out Carbide3d, but of course this happened on a Friday evening, so I’m not going to get a response until next week.

Any help will be kindly appreciated! Thank you so much!