I don’t mean to make a fuss or anything, but as a user of Nomad 3, I just want to get feedback.

I hope that users can communicate with each other about this issue and that the manufacturer, who is not unaware of the situation, can come up with some solution.

Sure there are small AC bearings available, but it isn’t just the size (in this case 708 type), it is the 24k rpm rating too. As I said, I have looked and none of the blue chip bearing manufacturers offer this combination so I suspect they know their limits. I have found the degradation to be much better running at 10k but sometimes I need the high rpm to get the surface speed with a small diameter cutter.

As for the OP’s worn shaft, they are available elsewhere but you’d need to put a thread on it, not easy if it is hardened.

https://www.aliexpress.com/item/1000007397444.html

I have purchased the ER11 shaft and am waiting for delivery.

But the bearings are the problem.

It’s not my place to comment here since this is outside my bailiwick.

Folks with problems with their machines should write in to support@carbide3d.com and we will do our best to assist.

I made an inquiry about support@carbide3d.

However, they told me to buy a spindle.

I asked about bearings or other reasons, but they didn’t tell me.

Replacing bearings requires an arbor press (or similar special-purpose tool) — we’ve had a couple of customers who had one in their shop use it to source bearings and replace them.

I wish I could live close to the manufacturer…

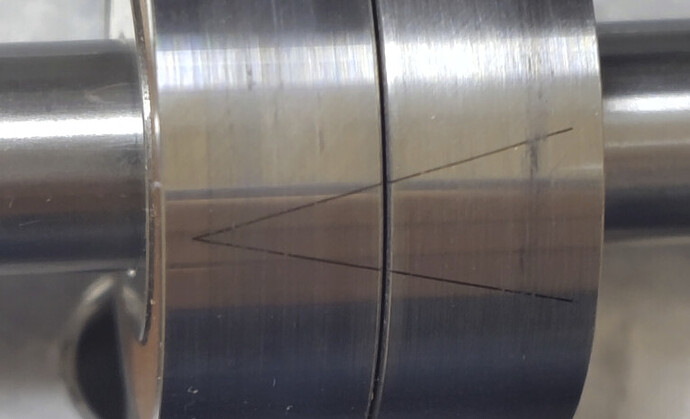

I took apart one of the previous spindles to remind myself of the bearing type.

The type is DB (Back to back)

The orientation marking on the side is for a duplex set :

The usual way to use a duplex set is with matched spacers on both the inner and outer races and the preload gap ground into the race sorts out the preload.

In the Nomad 3 spindle, they are not set up this way, there is no spacer on the spindle shaft so the preload is totally up to precision assembly and will vary due to thermal expansion differences between the ali spindle block and the steel spindle.

It’s probably one of the quick ways to just convert it into a different spindle.

This is what I did. I went with a 1.5kw air cooled spindle.

I have already ordered the new upgraded version spindle.

I was thinking about modifying it with a completely different spindle, but I want to keep it as original as possible.

I’m trying to figure out what I am gonna do with this 3rd one. I wouldn’t mind trying out the new spindle design. Have you thought of what to do with the spindle board? I’ve read about burnt up boards when the spindle stalls. I’ve for 4 boards now I guess I can risk lol.

I thought about changing it to spindles, boards, ball screw, nema23 if I do a renovation.

I thought of all that too. Figured I run it with the new spindle and see. Year and a half later with the machines running 5 hour days 5 days a week with little downtime, I think I’ll leave it alone lol. I pulled apart the stock spindle I had with little to no use and see some issues. It already has the discoloration where yours was eating into the shaft. I mean this had maybe 10 min of run on it. I think I have some ideas to try and address a few of the issues I see. Keep us updated if/when you get the new design spindle and how it holds up. I may try and keep this spindle design on this one.

So I was thinking of this last night. We don’t have a center bushing to apply force to keep our shaft from spinning on the inner bearing race. It seams like most of the damage is being caused because the shaft is slipping on the inner race and the inner race isn’t spinning in the bearing due to resistance. I know it would be very difficult to make the inner bushing. Then it occurred to me. I have some Loctite 628. This is a wicking version used to retain slip fit surfaces. I took apart two of the spindles and cleaned the surfaces. Applied the 628 and let it set up overnight. Let’s see if this gives enough hold so the shaft stops spinning in the race and actually spins the bearing as intended.

As I checked yesterday, the hardness of the shaft is weaker than the bearing.

Yep I suspected this. Explains why all the ware you see is on the shaft. Once it starts it just keeps getting worst. From my basic measuring tools, the shaft is .0015” smaller than the id of the bearing. Perfect slip fit but without any kind of inner sleeve to secure the shaft to the inner race, no amount of preload is gonna keep the shaft from not spinning in the inner race. Not without destroying the bearing first.

The upgraded new spindle has been shipped.

The lower part of the housing seems to have two double-sided contact bearings and the upper part seems to have one 708c.

They say it has 7000 series bearings, and I guess the shaft diameter has also changed from 8mm to 10mm.

When I replaced the existing spindle 3 times, the problem always occurred at the top of the spindle.

I just hope there won’t be any more problems.

Keep us updated. I did notice on the spindles I had the ware was on the top also. I think the constant side load from the motor is the cause. I ran my spindles on warmup last night and it was the quietest it has ever been. Very little heat build up as well. Let’s see how these hold up. I’m still worried about the underpowered motor. With 1.5kw I can cut .25” depth and .020” step over at 35 in/min in 7075 running 15,000 rpm. I have a feeling this won’t be doing that lol

If I try the upgraded spindle and this also has the same problem, I’m thinking of removing all the existing drive system parts of the Nomad 3 and changing everything from the board.

However, the basic structure of the existing Nomad 3 seems to have a lot of constraints.

I’m looking at DMC 2 MINI, but the user is so small that there’s not much information.

I can build it myself, but I think it’s going to be difficult for a while due to the surrounding conditions.

For now, I just hope the new spindle doesn’t cause any problems.