There have been a total of two spindle replacements while using Nomad 3.

All of them are the phenomenon of the spindle moving in the Y-axis direction, and if you look up the forum here, there are articles with the same symptoms.

Before using the machine, the spindle is preheated and then processed.

The spindle that was replaced shook little by little in the Y-axis direction as before, but it became too severe, so I took it apart to replace the bearing.

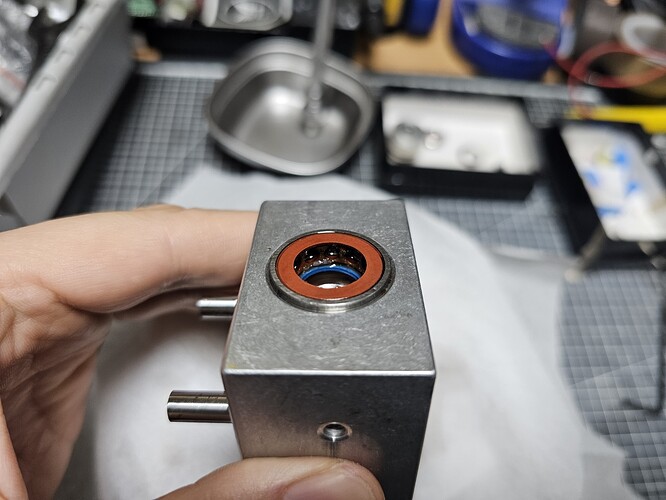

The inner part of the bearing below ER11 was stuck to the rod and separated, and all the iron beads came out outside.

The part that touches the upper bearing of the ER11 rod is tilted to one side as shown in the photo, and the groove is dug.

I had my spindle replaced about a year ago and it started shaking again without using it for a few months, and the shaking got worse and worse.

I think this is a very chronic problem with Nomad 3.

My Nomad 3 is out of warranty and I need to buy and use new spindles every few months to continue using it in the future.

The customer center didn’t tell us how to repair it and just told us to buy a spindle.

The ER11 bar is damaged and I don’t think I can use it, and I think I’ll have to find a different solution.

If you are using Nomad 3, please check by holding the bottom of the ER11 bar and shaking it in the Y-axis direction.

I hope you take action before it’s too late.

Thank you.

I’ve had similar experiences with my nomad 3 over the years. That said, I’m not sure what action there is to take here ![]()

Maybe the takeaway for others is to proactively check the spindle for this kind of wiggle and raise it to support before it gets too out of tolerance to be workable. EG: add this check to a general maintenance task list.

Of course if you are sufficiently out of warranty this kind of proactive replacement is less useful…you probably want to squeeze all the life you can out of it before paying for another. (My nomad 3 is going on 4 years old I think ![]() )

)

Maybe the folks at carbide have other ideas or suggestions.

And just for the sake of brevity, it’s worth mentioning that these are fairly tight tolerance press fit bearings. But if one is sufficiently equipped, it’s almost certainly possible to carefully eject the old bearings and press in new bearings. (If your spindle is going in the bin anyway, what’s the harm in trying? Ruining a couple new bearings I suppose ![]() )

)

Though I’m not sure if there’s anything to be done about the wear on the spindle shaft if it’s to the point where it’s no longer usable…that’s a lot trickier to deal with at home.

This might be a mistake on my part to share this. I have not seen any other posts, but 6 months ago I was told not to post about this for “A couple of weeks”. And I have refrained from posting while waiting on official announcements.

There are beta units going around. Or maybe I have a one-off of a new spindle design.

And from my use and testing it is now a completely different machine.

It is sad that so many have the spindle issue. These are 3 of my 5 replacements.

Maybe they felt bad for me? But I see this new spindle as a much better solution than hoping that the old one will last or that the user won’t notice.

How can I get these spindles?

I was contacted by Carbide3D - They made it. I would hope they made it as a replacement to the current design. Or they are working on a new Nomad.

The marked has changed a lot. I would not buy a Nomad 3 again given the current competition.

I hope you will be able to buy it. But in my opinion they should do a recall of the current spindle.

I’m trying a few things, but it’s hard.

I think so, too.

It’s a defective product, but the warranty that I couldn’t recall has ended, so he asked me for about $114 including shipping costs.

If there is no such problem, I will be willing to pay for it, but I’m sure there will be a problem if I buy a new one. Is it right to buy it?

It also seems to be a serious issue to consider in Carbide 3D.

There is no sign that it is available for purchase unfortunately. I wish it was. And it should have been for a long time.

@wmoy may have some answers. He sent me the beta unit and it mad my experience 100x better with the Nomad.

I can’t stand idly by while so many have the same issues. This should be resolved once and for all.

I agree with what you said.

Thank you.

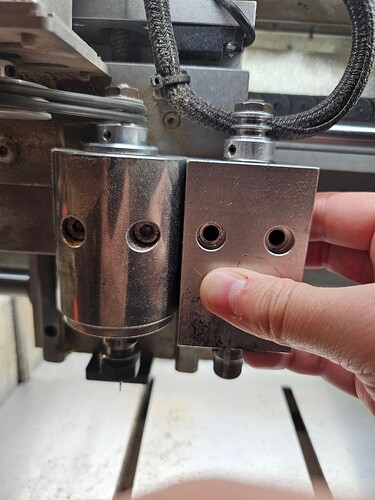

Looking at the picture, the height of the round block where the shaft is put looks shorter than the existing square block.

It looks like the shaft length of the existing 100mm is a little shorter.

I’m sorry, but can you tell me how high the circular block is?

It’s actually longer.

Thank you!

Interesting stuff. I am also on my 3rd spindle and it is starting to get play in the bearings again.

I researched the bearings used in the original design and they are a bit of a unicorn, no other manufacturer makes angular contact bearings at that RPM in that small form factor. I concluded that maybe they can’t actually meet the advertised specs and this has put C3D in a very awkward position.

I had contemplated making a new spindle which took more mainstream bearings and this beta unit appears maybe to do exactly that. I would just love to get my hands on one of these to test and feedback on.

I am clueless. Where/what is the ER11 bar that I should check? Thanks.

Remove the lower collet nut and hold the lower part of the spindle and move it back and forth.

It’s pretty clear something went wrong in design.

edit: Misumi makes angular contact bearings that small. Fairly confident maybe if you had the measurements for the space the originals took up?

Edit: strange… misumi says they only go down to 10mm but we have 5mm id ones at work…

I don’t know how it is because I haven’t used the new round spindle in the picture above, but it seems that the original spindle is a misdesigned product.

But there’s no way I can appeal strongly to the manufacturer about the recall of the existing spindle.

I can be sure that most Nomad 3 users will experience the same problems as me.

I had no solution, so I asked the manufacturer if I could buy a new round spindle and received a reply asking for $75 + shipping charge.

But there is no definite answer about whether you are sending me a new spindle or an existing spindle.

It contains OD-22mm, ID-8mm, and H-7mm bearings.

It usually comes out as a 608 bearing and is a non-contact type bearing with both sides blocked.

By the way, why hasn’t Carbide 3d responded to this post?

Winston is in Japan on vacation it seems. But maybe @WillAdams can chip in with a comment?

I am sorry for probably stirring up some drama. But it has been almost 6 months.

The top bearing on the round spindle is probably the same size. But I think there are two.

But the bottom bearing is different:

The 6000 series bearings we have at the bottom of the spindle are rated for several times more load than the ones in the prior generation

There are also new “labyrinth seals” so no more debris in the bearing hopefully.