I love my S03 router because it has so much power compared to the Nomad. For that reason I tend to use it 95% of the time. I have only been using the Nomad occasionally when I need something very precise or when I don’t feel like walking to the garage to fire up the SO3 (my Nomad is in a spare room in my house which is handy sometimes).

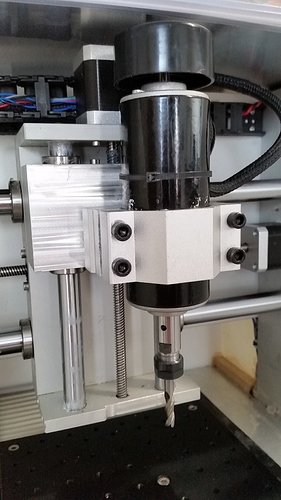

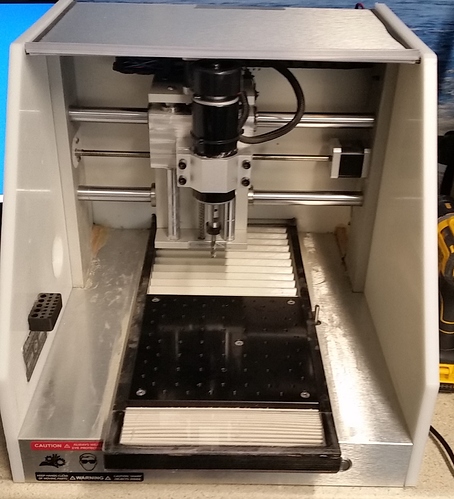

So, I modified my Nomad to accept a 500 Watt brushed DC spindle ($140 on Amazon) https://www.amazon.com/gp/product/B0154MW4E8/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

Caution: performing these mods will void your warranty if you still have one. The mod requires you to disassemble the Z carriage, cable track and housing panels but that only takes about 20 minutes. You just unplug the stock spindle motor and unplug it from the control board. This is a cheap Chinese spindle so I don’t know how long it will last or if it is really capable of 500 Watts but just playing with it I’m sure its much more powerful than the stock Nomad spindle. The item description claims 12 krpm but I measured 10,200 rpm so I suspect the power numbers are probably inaccurate also.

The stock Nomad spindle is somewhere around 50-70 Watts which is pretty anemic even when using a 1/8" cutter. For comparison the SO3 router is closer to 1000 W (well over 10x more powerful after accounting for efficiencies). I routinely run the SO3 at 120 IPM using a 1/4" cutter and 1/4" DOC in soft woods and plywood. For comparison the stock Nomad isn’t powerful enough to practically run a 1/4" cutter but if it could I would have to run at around 5 IPM compared to 120 IPM on the SO3. Its kind of a big deal because the Nomad mechanicals are capable of a lot more and its really a shame that its so limited by the spindle power. The spindle is the weak link by a long shot.

With this mod I loose closed loop speed control but since the spindle is around 10x more powerful as the stock Nomad spindle that’s not really an issue until I start cutting closer to its max power. The spindle power supply has a potentiometer input which controls the spindle speed via PWM power signal. You can see that I mounted the speed control on the side of the housing and the power supply to the rear of the housing. The speed range is zero to 10,200 rpm but since its PWM you loose a lot of torque at slower speeds so that’s not optimum. However, I run my SO3 at 16,000 rpm (its slowest setting) 90% of the time so I don’t think running at 10krpm to get max power is going to be an issue. The power supply does have an input that allows a speed control input via Mach3 but it wasn’t worth the trouble to me to mess with that.

This mod required one significant modification to the Nomad which is milling the face of spindle block flat and adding 4 threaded mounting holes for the new spindle mount. I also relocated the tool touch probe but it would be easier to add a simple offset plate and leave it in the stock location.

I have it all back together and working but it appears that the PWM signal from the spindle power supply creates too much noise for the Nomad control board to handle. So, next step is to run shielded cable to the spindle and ground everything properly. If that doesn’t work I’ll add some ferrite beads and capacitors to the spindle cable to isolate the noise even more.

If any of you have questions, comments or suggestions feel free to fire away. I’ll be glad to help wherever I can. I’ll continue to update this thread as I make progress.