Ok

So couldn’t wait to get the thing when i got it , it just sat there nagging at me. ( too many things to do)

for about a week or 2 intstalled the software and proceded to make the first cut. all i tried was “engraving” with the ballnose a few letters should have been pretty strait forward. looks like my MC settings where off a bit : no spindle spin it crashed in the wood part ( peice i had laying around) so cracked up my friend google and whent and look for some gcode practice ( raw Gcode )

so 2nd test was going square ( moving all axis ) and starting motor and then ending the program.

that all whent swell but did not have time to play with the beast for a while where april and a few days ago hooked the thing up to the PC again whent into windows and proceded to launch a Gcode i was working on for the 3rd try . the code consisted of just miling slots for a fan in the PC . (will try to attach images later. ) wasn’t that strait forward . had a few things wrong the endmill was crashing in the table and stoping the spindle. i had a Z-0.25 at the beggining ( the part was only 0.0600 thick ) fixed that all went swell till windows hibernated ( grrr. ) did not have time to retry till the next day. turned that off and did a 3nd try ( finishing the necessary slots for the fan) and all went good . so 3rd time was the charm literally.

so just got some more matts to play with ( still haven’t used the stuff in the kit tough) still wondering what to do next.

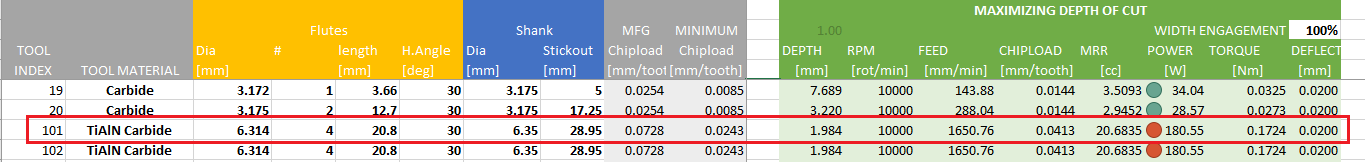

btw speed 10k rpm , F4 and about 0.0050 per pass did not have any problem with the aluminium. (probably could go much ticker on the passes)

i would recommend ordering the vise ( that i do not have) would make fixturing much easy. Also getting a/some 1/4 end mill as well as a collet for it .