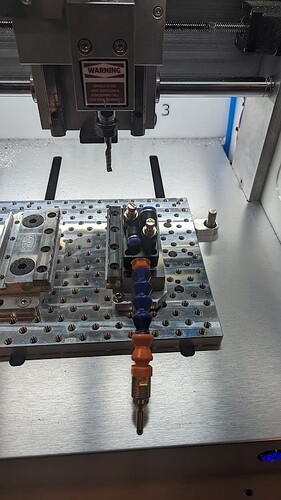

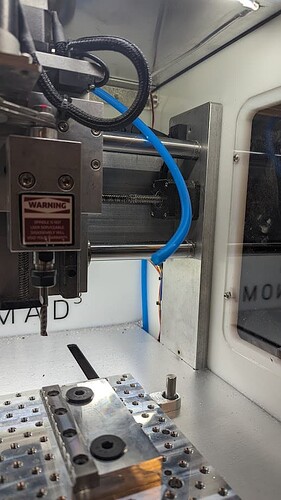

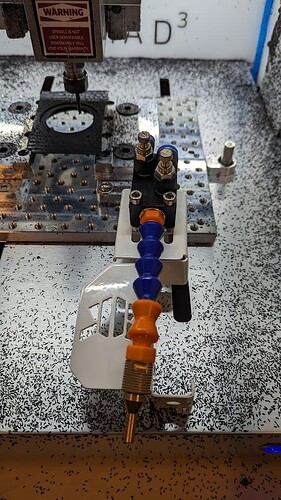

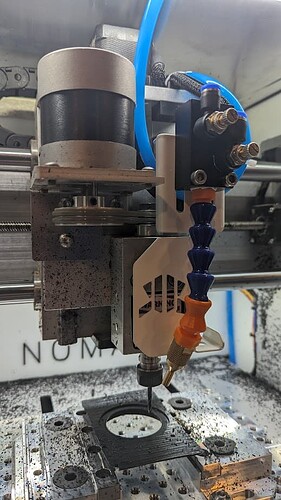

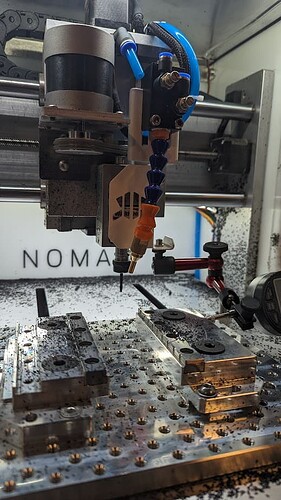

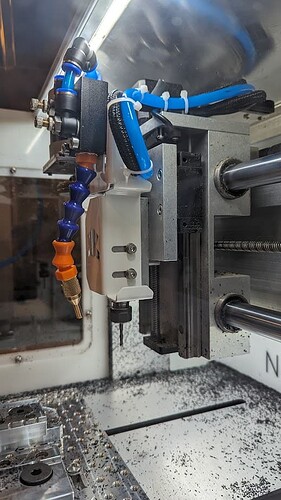

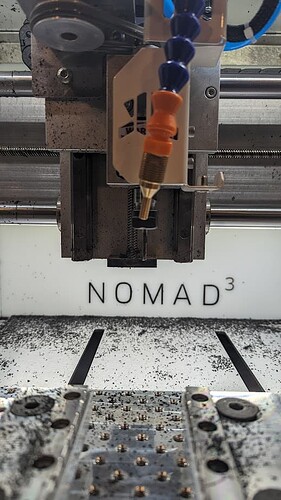

I had to modify the bracket, but it is complete!! (except for the fact that I have no real easy way to turn the air-blast on or off in between jobs, or changing tools etc. I would LOVE to have the machine control a solenoid but that’s a bit too much work simply because I am lazy, but I would love to find an on/off switch (preferably something that doesn’t require power)

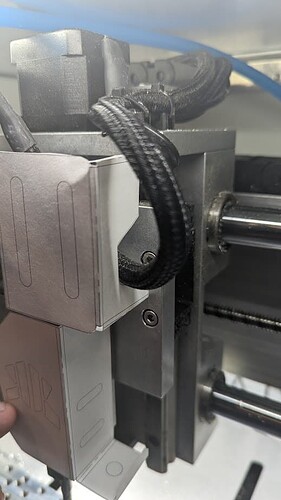

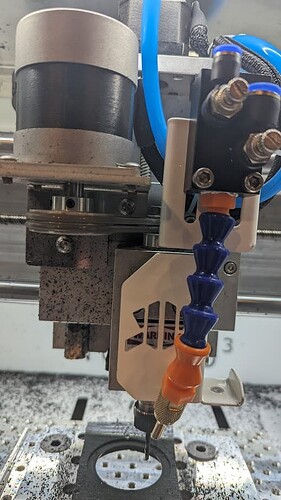

I added the nutsert this evening, and to my pleasant surprise the arm for the indicator was able to thread in, (i was concerned the small amount of thread wouldnt be able to reach inside the nutsert)

I will be honest its a giant pain to put the indicator arm into place, or at least it was when the Z axis was where it was. It would definitely need to pretty much be at the very top of its travel in the home position so you have enough room for your hand. A small little wrench for that will definitely be needed to snug it up. I dont use it all that much since the SMW jaws have the indexing pin that keeps them pretty much dead nuts aligned to the machine.

[while i was typing, i found switch that looks perfect for what I want to do. I will just block off the secondary out port, and leave it for future use.]

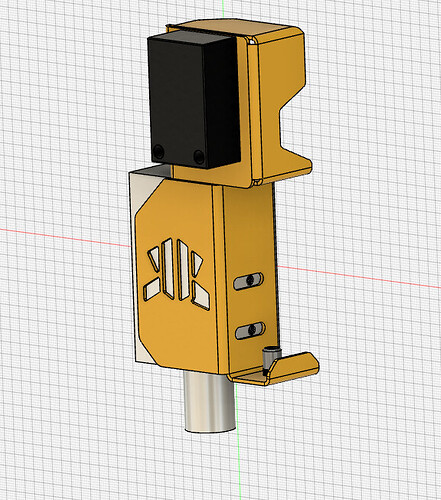

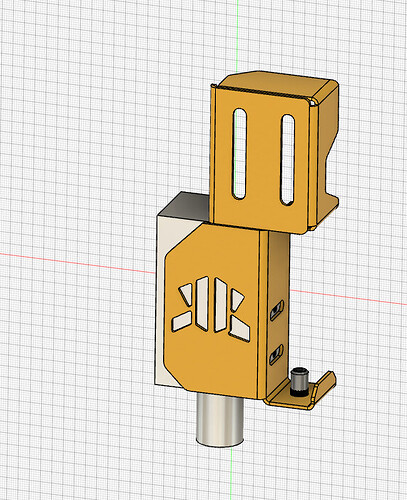

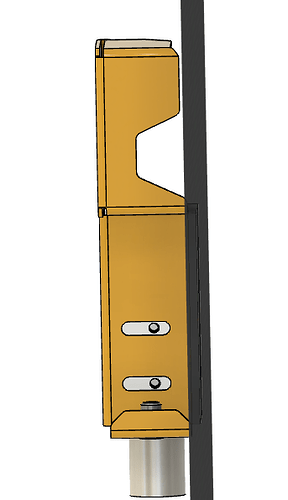

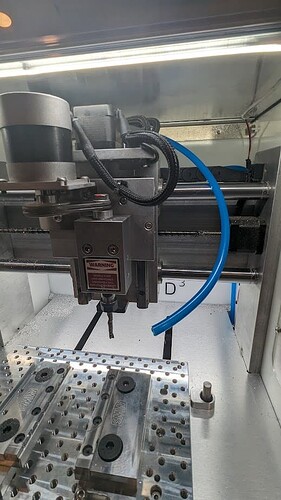

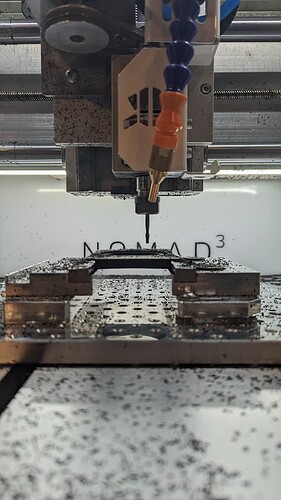

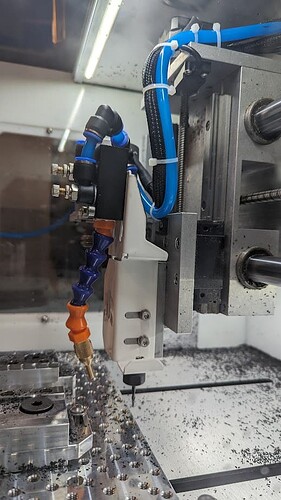

As I mentioned, I did have to modify the bracket, because the tubing and motor wiring needed to move up past my notch when the spindle was at full droop (i tested below the bottom of the SMW plate, and while I will never need that much travel, I want the machine to retain full functionality.)

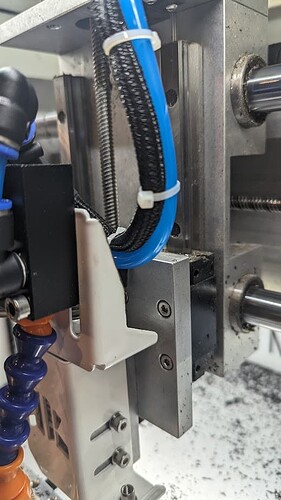

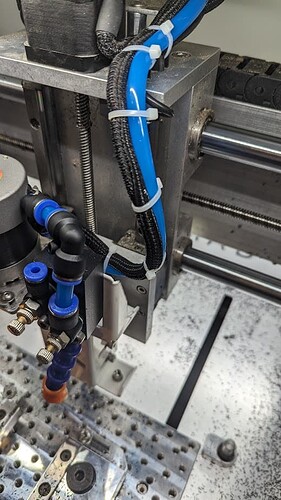

you can see above that I had to cut the notch out, so that the wiring could move up and down.

feel free to gander through the rest of the glorious (indulge me…its been a lot of revisions and patience.) photos of the setup. and dont hate me for using white zipties, its what I had on hand, and theyre the tiniest ones i had, and technically its recycling since they were never used with the product they were provided with.

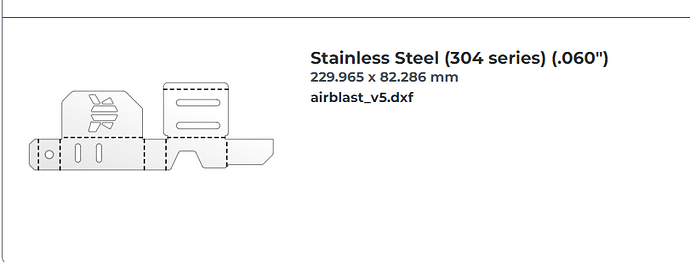

i am going to try and work on getting the fusion file updated with the notch so it can be cut by others via sendcutsend or whatever method you desire.