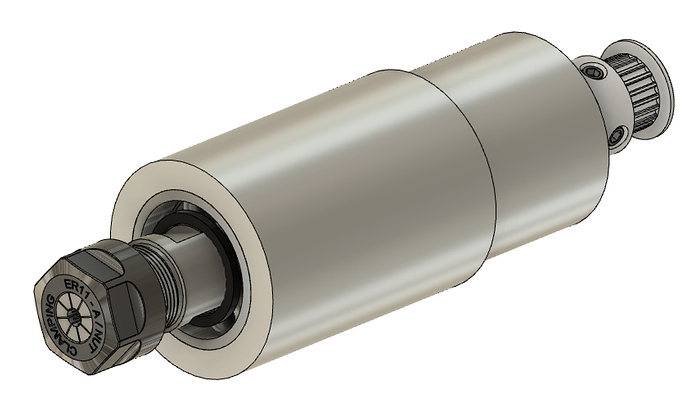

I realize the subject of this thread is somewhat misleading, this started as a spindle motor modification but like any good project I’ve now totally gone off the rails. New spindle arrived and I finally got it assembled late last night after some spur of the moment design changes to add a port to the side for through spindle air blast for chip management and cooling.

I have really been liking the power upgrade to the machine but cutting harder with the Nomad means more noise. Disclaimer: I genuinely think the Nomad is an awesome machine, the fact I can accurately cut aluminum on my desktop is hilarious. I just want to see how far I can push this platform since the machine is built like a tank.

I ran stock configuration, then put Dynamat (automotive grade sound deadener) all over the inside of the machine and then installed my new spindle, running a bunch of tests with identical cutting parameters; 9,600RPM, 12.8 in/min, .040 step over, and a DOC that ramped to .040" at the end. Sound measurements were with iPhone 12" away from the machine.

- Stock measured 91 dB (well, stock with 125W spindle)

- Dynamat was 86 db, biggest bang for the buck was the aluminum top plate, the rest of the areas didn’t seem to make much of a difference. Took me about 3 hours to get everything installed, dynamat is a bit of an arts and crafts session. Wear gloves and buy the roller, you will thank yourself.

- Dynamat + new spindle, 75 dB!!! It sounds so good, only 5 decibels louder than just the spindle. Eventually, I bumped the feeds to 200% or almost 26 inches a minute and the machine was loving it.

More tests to come!