Hi there

I am new to CNC machine and I am trying to get my hands on one. I been doing some research and narrow down to Nomad and Shapeoko. I know that there is price difference between them but there are both within the budget. I noticed the Nomad has a smaller cut area but it is the more expensive one within the two. I also noticed that Nomad is ‘read to run’ compare to Shapeoko require assembly. I am worrying that if I can’t get the assembly right and get to the point that I am so frustrated that it would be $1000 sitting on my desk. But I also feel like Shapeoko 3 is more customizable and more room to upgrade to bigger cut area such as XXL. Also, if I run into problems which of the two may i more likely to get help with on the forum.

I saw that there are comparison between shapeoko and Xcarved but I didn’t find anything between these two.

I would appreciate any input that you have.

Thank you

That’s pretty much it:

-

Nomad 883 — ready to go out of the box, for cutting 8" x 8" x 3" or smaller pieces. Self-contained, well-suited to small, detailed projects, incl. metals (note esp. its use for a small titanium pocket tool)

-

Shapeoko 3 — a kit (which is designed for assembly and is quite easy to assemble, though the larger versions may entail some physical effort — the boxes alone are quite a bit heavier than the ~60 pounds of a 16" x 16" x 3" cutting SO3. I’m not aware of anyone who has been unable to get a machine together and operational when working at it in good faith. There have been a couple of people who expected more than was promised and out of resentment gave up on the machines, but if you can turn a screw, you can assemble a Shapeoko.

If you want to do small, intricate work, get a Nomad.

If you want to do larger scale work, then get an SO3 — you can still do small detailed work though — it just has a larger work area and uses belts: http://www.shapeoko.com/projects/project.php?id=154

Thank you Will!

I have no problem with belt driven, as matter of fact, I think belt works better with newbie.

What I mean with assembly is I worked with milling machine before, and I know the margin is small and if the the frame/kit is not up right then it might transfer to the work. Right?

While belts are more forgiving, the Nomad is built w/ home / limit switches, so even a naïve user should not need to worry during ordinary usage, or even when first beginning and learning.

The Shapeoko 3 is designed to be self-aligning during assembly, but yes, any misalignment in initial assembly will telegraph into the work. That said, the tolerances for manufacture are quite tight, so even a quickly-assembled machine will usually work quite well.

We have some information on calibrating and squaring the machine: http://www.shapeoko.com/wiki/index.php/Calibration_and_Squaring_the_Machine as well as fine tuning: http://www.shapeoko.com/wiki/index.php/Tuning

I believe the primary driver of choice between the twain should be the scale of work which you wish to do — tiny/small: Nomad, medium–large: Shapeoko (but if budget is a consideration, then get a Shapeoko — it does okay for small work as I hope I demonstrated).

EDIT: However, if there are other concerns, such as noise, then they should over-ride.

I have both machines. My Shapeoko is a XXL version.

Think of the Nomad as a +/- 0.001 to 0.003" accuracy machine for small parts.

The Shapeoko is more like a +/- 0.005 to 0.010" accuracy machine that can make larger parts than the Nomad. With the Dewalt router it can remove material about 10-20x as fast as the Nomad which makes it my go-to machine for most parts.

The Nomad’s spindle is way underpowered so you have to take very small cuts compared to the Shapeoko.

I still use my Nomad for small intricate parts but I like using the SO3 much more. Others may like using the Nomad better. It really depends on what you need the most.

With that said, I ran a 17"x17" test square on my SO3 and it came out 17.000x16.997 which blew me away. However, I’ve had some features off by as much as 0.010". I’m still trying to figure out what variables affect tolerances. I love being able to cut out large wood parts with a 1/4" bit running 0.25" deep and 120"/sec though. With the Nomad you are practically limited to a 1/8" cutter or smaller and about 5% to 10% the of the material removal rate of the SO3.

Feel free to ask more questions if this spurs any new thoughts.

If you haven’t yet, please look into http://www.shapeoko.com/wiki/index.php/Climb_vs._Conventional_Milling

Thanks William! I am hoping to do some large scale work, so I am more interesting in Shapeoko 3 now.

Thanks for you input Tony! I am now more interesting in Shapeoko, because I am hoping to do some medium to large scale work. So it is the matter of spindle now. I am curious how loud is the Dewalt router? because I live in an apartment and it is not really sound proof. I am now ready to put my order in? Is there anything else (material/ bits/ others) I should order along with? Thank you!

The DWP611 is moderately quiet for a power tool — the problem is, you’ll also need dust collection, and the sound of cutting itself adds noise.

If you life in an apartment, and sound is a concern, then you should probably get the Nomad, and a Festool vacuum.

See http://www.shapeoko.com/wiki/index.php/Soundproofing_Enclosures if you’re dead set on the larger machine — there are some threads here as well.

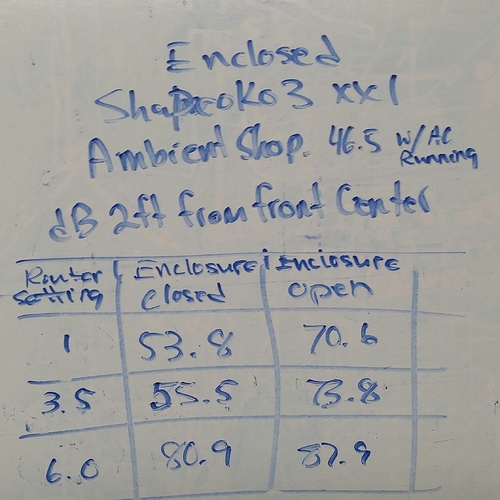

My SO3 XXL inside an enclosure I made for itis quieter than the Nomad when cutting the same material at the same speed. However, if I’m hogging out a lot of material then its louder. Here are some sound measurements I ran on the SO3 with the enclosure open and closed. Unfortunately I don’t have measurements for the Nomad. as you can see, the noise goes up considerably when the router is turned up to full speed. However, so far I haven’t used it above its lowest setting and everything has worked great.

With some refinements these numbers can be brought down quite a bit.

I run the Dewalt router at the lowest speed most of the time (probably not ideal from a feeds and speeds perspective) and it does great and its very quiet when the enclosure lid is shut. I have a thread somewhere on this forum that has more info about the enclosure.

The Dewalt router has closed loop feedback to control speed so it maintains the rpm setting +/- even when the load is changing. I bought it from C3D with my S03 and I really like it a lot. I also bought a precision collet set for 1/4" and 1/8" bits from precisebits.com.

Will is absolutely right, you will need dust collection with the SO3. Remember, its cranking out 10-20x as many chips per minute as the Nomad. I just built my own dust shoe (I’m still tweaking that design) and I run it through my shop vac. My shop vac has a bag and a low micron filter and the shop air particle counts (per a Dylos DC1100 pro laser particle counter) never get over 30,000 particles >0.5 microns which is good. Outside particle counts can get over 120,000 particles/ft3 to get a comparison. When I was milling my MDF spoilboard I placed the meter inside the enclosure and counts were over 1,200,000 but ambient shop particle counts were under 30,000. You just need to make sure you buy one of the best vac filters and use a bag to keep the filter relatively clean. I recently made a cyclone collector and put it upstream of the vacuum and it catches 99+% of the larger particles so the shop vac bag doesn’t fill up.

I think the Nomad would be okay without dust collection if you seal up some of the holes in the enclosure. Some of the small particles will escape but it will be a fraction of the level inside the enclosure. Just adding a port in the wall of the Nomad enclosure to draw a vacuum would ensure nothing escapes. Again, you need to make sure you are using a filter that captures particles down to 0.5 microns or so.

What to get with your machine…

Nomad:

–1/8" and 1/16" carbide endmill and ball mills. I’d get at least two each. Don’t worry about anything larger, its really not worth it for the Nomad. You may want to get smaller ones at some point if you want to so very intricate work.

–The aluminum “sea of holes” base is nice for holding parts down. I also got the vice but I don’t use is much. Some use the vice a lot.

–I bought a flip jig but I haven’t needed it yet.

SO3:

–You need to supply your own spoil board if you buy the XXL. I think the smaller versions come with one.

–Same bits as mentioned above plus add 1/4" bits

–I like the Dewalt router so I recommend getting that when you buy unless you know that you will need to go below 17,000 rpms. If so there are $300 to $400 spindle options which include speed control or you can add the SuperPID to the Dewalt. IMO, you are better off just going to a brushless spindle if you are going to spend more money. I’m happy with the Dewalt router though.

–Precisebits.com collet for 1/8 and 1/4" bits. Not necessecary but the Dewalt only comes with a 1/4" collet and its not as precise as this one. Its probably fine for most jobs though.

–An enclosure, a shop vac with a good bag and filter and a dust shoe to catch dust as you cut.

Here are some pictures of my SO3 setup…

Why isn’t the Shapeoko XXL as accurate as the Nomad?

Can anything be done to the Shapeoko XXL to increase its accuracy?

- Belts vs lead screws

- V roller guides vs Recirculating ball bearing guides

- The Nomad frame is much more rigid

- Router vs precision spindle

- Long travel vs short

After proper setup and calibration. … the main changes that could make the SO3XXL more accurate are…

-

Stiffer z axis gantry setup. It’s improved over previous versions but it flexes an order of magnitude more than the support beam.

-

Add supports under the base cross plates (XXL version). The floor deflects a lot with just a little force. This is as easy as placing blocks cut to the proper thickness under the beams.

-

Leadscrew, ball screw or rack and pinion drives.

The repeatability on the SO3 is good so just taking very light and slow finish passes may help a lot. It would take some time and a lot of measurements to figure out how to optimize the SO3 accuracy.

Will may have a better answer than I do since he’s been using the Shapeoko for much longer than I have.

That’s pretty much it. Physics are inexorable.

That said, the accuracy deviations of a ShapeOko are still quite small, and the precision is quite good.

I’m still faintly surprised no one has done an Acme / trapezoidal screw upgrade. It was one of the first things done for the Shapeoko 1, and should be fairly simple to do — I did some sketches, and made some notes, and put a parts list on my wiki page: http://www.shapeoko.com/wiki/index.php/User:Willadams#Acme_screw

Still wider belts and pulleys might help, but they don’t seem to be available in GT2. Sourcing 9mm belts Made in the U.S. may be an improvement — I bought belts and pulleys from SDP/SI — might not make a real difference, but made me feel good.

The only other low-hanging fruit for this sort of thing I can think of would be a positional encoder, which would require a new controller, as well as sensors and strips/wheels or some other measurement system. See the LoboCNC for an opensource implementation of this.

I don’t know how much it would add to the cost or if it can be implemented reliably but if these machines could use linear encoder strips like are used in standard inkjet printers combined with a stiffer Z axis assembly, the accuracy could be very good. It would allow the machine to slow itself down if needed to maintain accuracy too. There must be a compelling reason they aren’t used because I haven’t seen them in consumer 3D printers either and they’ve had more money thrown at development and a longer time to evolve. I would be interested to know why they haven’t been used. I’m sure there’s a good reason that I’m just not aware of.

As I noted, positional encoding was used to good effect in the LoboCNC — it seems to add quite a bit to the cost, unless one can score the perfect bargain on parts, which that running out seems to be part of why it’s no longer produced.

3D printers have such low forces, there shouldn’t be a need for them.

I missed the Lobo comment. Thanks Will!

3D printers still have issues with belt stretch and thermal expansion affecting accuracy. I think everyone has come to expect that they aren’t going to be good for better than +/-0.005" at best so it hasn’t been pursued further. There are major price wars too so that’s probably another reason. I’m sure CNC mills and routers will be in the same place a few years from now.

Thank you for all the details you provided! I really appreciate it! You have a very nice setting for your CNC milling machine! I really like it! Thank you for sharing it!

My $.02 as owner of Nomad and Shapeoko XXL, and very much a CNC newbie (with a wee bit of 3D printing experience but not a lot) myself:

Nomad is much more turnkey than XXL. Making parts within an hour or so.

I’ve done Hello World on my XXL, but I’ll be puttering for a while to get to my first project that isn’t about bootstrapping the machine.

XXL is huge awesomeness though.