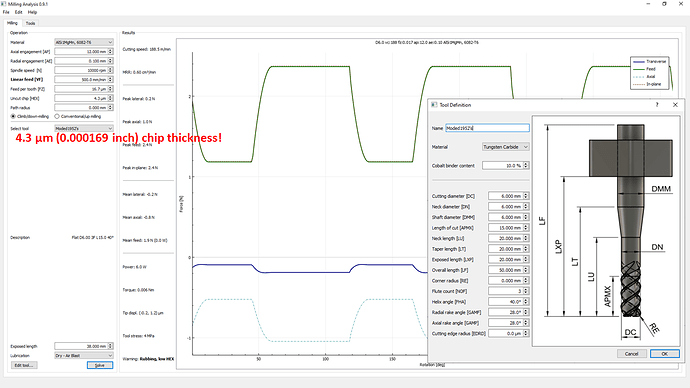

I adjusted the endmill rake angles in Milling Analysis 0.9.1 to get it to match your HSMAdvisor results as shown here:

That would be really nice if that small chip thickness was achievable (it’s 1/6 what @Julien, @Vince.Fab, and others would likely use).

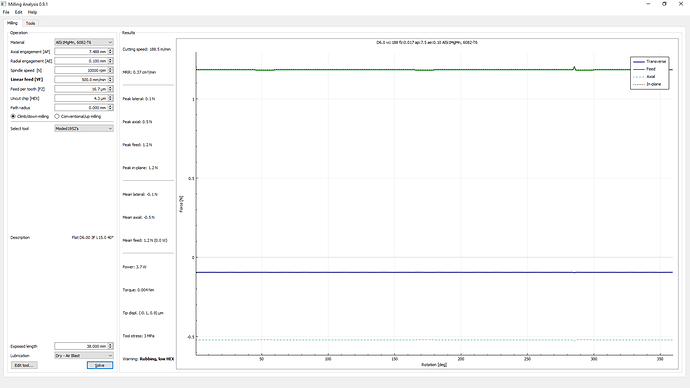

You might want to try reducing the axial DOC to smooth out the cutting forces as shown here:

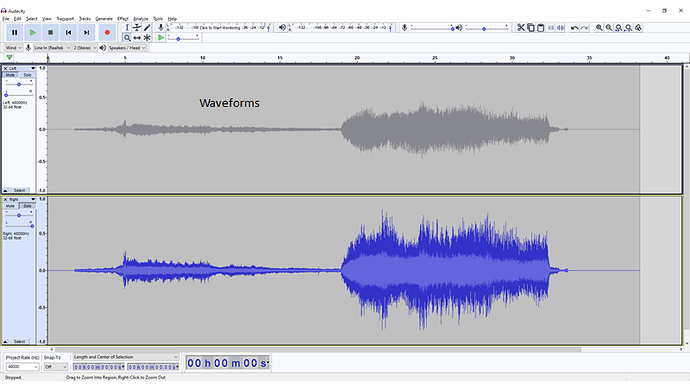

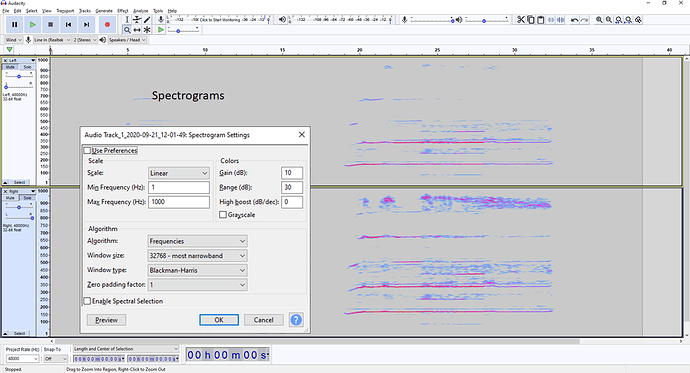

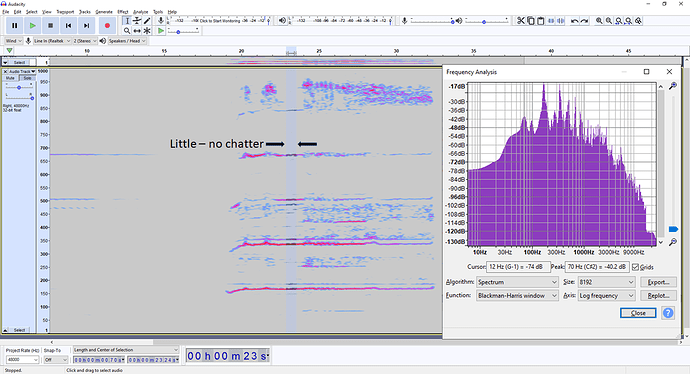

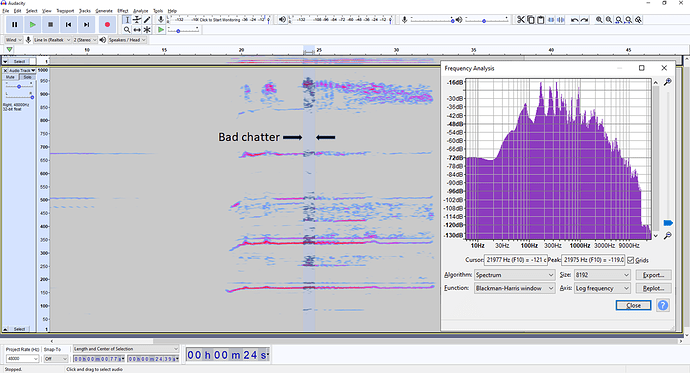

Using Audacity, as shown below with you video, might also be helpful in analyzing forces and chatter.

I don’t know German, but isn’t nass (water spray) kuhlung (cooling) recommended for that endmill?

OOPs I forgot to mention that less cutter stick-out from the spindle’s connection to the gantry might help too (elevate workpiece too?)