Disclaimer: I won’t have test results for this modification for at least a few days, so cannot call it an upgrade at this time but I was happy to take this modification risk. Time will tell and I’ve been proven to be an idiot before.

Nerd disclaimer: I cannot say with certainty analytically the lead screw is starting a buckling mode; column buckling results are highly sensitive to end constraint conditions, you could definitely debate which one applies which would make a big difference to the result. However, there were factors that empirically pointed to buckling mode, I had some free time and things happened…

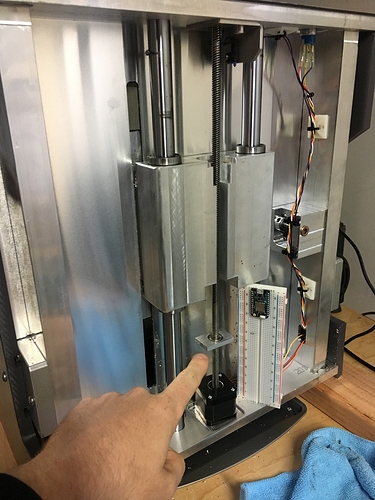

I’ve been moving my Nomad around a lot building up a workbench and was looking at the bottom side of the machine; specifically the y-axis lead screw and carriage design. The lead nut is on the opposite side of the carriage as the stepper, which can assist with making the machine more robust to slight misalignment of the lead screw, lead nut and rails but also results in long unsupported length to lead screw diameter ratio, especially when the carriage is toward the front of the machine. Length to diameter ratios don’t matter in tension; you can pull something with an infinitely long string but you definitely can’t push anything with it.

Other users have noticed the machine tends to be louder cutting traveling in one y-axis direction than the other; noisier moving in the direction the lead screw is pushing (compression/buckling mode) and quieter pulling (tension/buckling impossible). I’d bet at least $3 that this is due to the lead screw starting a buckling based vibration mode.

In fact, with the pitch of a quieter machine, I got the wife’s permission and then did bet $3.

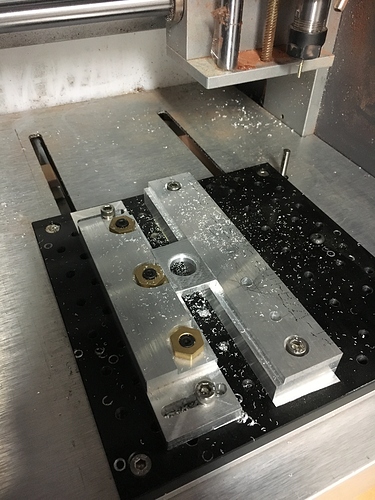

Starting with 1"x1.5"x.25" 6061, slapped it on the Nomad and rough cut out a bore and counterbore for the retention flange. Using a spiraling wall finishing tool path, tried real hard to hold bore diameter to +/-.0008" which was a challenge interpolating with a desktop machine and inspection equipment from Harbor Freight.

Obviously, after totally nailing the bearing fit, I decided to add magical bearing fit compound, just for added niceness.  This 8mm ID flanged bearing is the nicest one I could find on Amazon for under $1. (To be honest, a bearing is overkill for what I am describing, a bushing would be just fine and maybe better.)

This 8mm ID flanged bearing is the nicest one I could find on Amazon for under $1. (To be honest, a bearing is overkill for what I am describing, a bushing would be just fine and maybe better.)

From there, I removed the lead screw assembly, slid the bearing block onto the lead screw and reinstalled everything. You are probably wondering what I am going to do with a bearing block with no fastener holes. The faint of heart should just stop reading now.

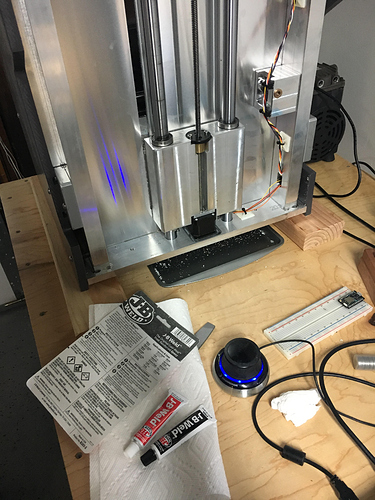

JB freakin’ WELD! Based on expected interface area, this joint would be good for a few hundred pounds of shear load and this interface can only take shear with no tension or compression component since the bearing slides on the lead screw. For this application, it is actually perfect, for reasons explained below…

After cleaning and prepping the bearing block and the existing Nomad y-axis carriage, I applied JB Weld to the mating surface being careful not to get any near the bearing. For good measure, added more to the exterior as well. It is incredibly important that this is all done with all the Nomad components securely tightened and carriage fully retracted such that the lead screw position serves to master for alignment, which is why using something like JB Weld is used since it will allow the bearing to slide to where ever it want to go to align to the lead screw before it sets in place. (This could also be solved with threaded holes in the carriage and oversized holes in the bearing block to allow it to float into alignment before tightened but this is much more involved retrofit…but it would also be reversible if this idea ends up being a disaster.)

The results, on paper, could be pretty massive. At the limit of travel, the unsupported lead screw distance goes from 14" to 8.5", which turns into a 2.7x increase in buckling load carrying capability. This should increase apparent stiffness and reduce noise! JB weld is cured, I’ve moved the y-axis around with the machine unpowered by hand and it feels happy with no binding. Lead screw feels way stiffer radially with the new alignment bearing. I may need to update the grbl $131 parameter to slightly reduce y-axis travel soft limit, we will see.

We will see, some side by side tests are planned against a stock Nomad belonging to another CNC enthusiast soon to see how my hunch compares to reality.

Hopefully this is a slam dunk, based on the size of the ground rails on the Nomad, this thing should be a freaking tank and capable of much more aggressive cutting.

Increasing machine stiffness would also be the first step before adding more spindle power…

to be continued