Hi guys, first post on here but been CNCing since the spring. Currently own a 35x35” Millright Mega V but hoping to get a Shapeoko as a second machine, due to its hackability, this community and documentation of what people have done with their machines.

So I’d been thinking for a while of my perfect enclosure design that could house the two machines stacked on two shelves one above the other, before realising that the entranceway area to my house is the perfect size to convert to a ‘CNC room’ - about 120 x 160-ish space leading to a corridor where a door can be installed, converting the space to a massive floor-to-ceiling ready-made ‘enclosure’.

This is one of two entrances to the house so is strictly speaking unnecessary, and right next to the room where I do all my making. Meaning I can move the machines and shop vacs etc into the room, and have loads more space!

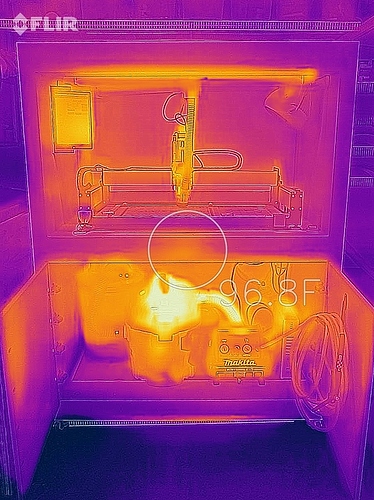

I am currently walling off the exterior door and installing a door to the new ‘CNC room’. I’ll be adding an extra layer of two of plasterboard with probably some green glue between to the walls. Next, my plan is to attach rails to the left and right walls (with supports going to the floor), which will support two shelves - my current Mega V below, and the new Shapeoko above. There’ll be a crawl space at the bottom in case I need to get to the far side of the shelves, which will hopefully be rare, and that space I can also use for shop vacs and storage. The shelves will technically be a little too high and a little too low than is 100% comfortable when working with the machines, but I don’t mind making do with a little step/stool respectively.

The main problem with this is the fact that the shelves will be in direct contact with the walls - directly transferring all the lower frequencies through the house (timber-framed). So I was thinking of decoupling the shelves by putting some thick stiff foam between the wall rails and shelves, and have the shelves ‘floating’ (not fixed down - so the shelf just sits on the rail, with foam between) and foam between the edge of the shelves and the wall to prevent lateral movement. The second part of the decoupling would be foam under the machines.

What do you guys think of this general design, and do you have any pointers for the type of foam to use? I live in Japan so will probably be using generic foam rather than specific brands (would ship from the states, but due to COVID shipments seem to be taking a very, very long time to get here). Was thinking of using those 10mm thick jigsaw style floor tile things, cut into strips and layered a few thick, as they are cheap, easy to get hold of in bulk, and not too flimsy. The Mega V is a little heavier (I think about 60kg total) than the SO and uses a rack and pinion system with fast rapids, acceleration/deceleration, so might need more substantial decoupling than the SO.

This design is also favourable to me due to ease and speed of set up. I want to get my machine transferred over the next couple days and running in its new spot as I have some parts that are time-dependent.

As a second point, but I can address later - to absorb the mid to high frequencies and prevent ‘drum syndrome’ was thinking of lining the walls with 15 mm styrofoam, milled into a zigzag surface pattern. Improvements to this idea also appreciated!

Thanks in advance for any thoughts.