I recently fell down this slippery slope, and regret nothing

I looked over all of the enclosures within the Enclosure Zoo, watched lots of youtube videos, read webpages, and followed advice (like @LiamN suggestion on Rockwool).

I ended up with a large structure that sits in my garage. The wall that the machine is up against is shared with a bedroom inside the house. My kid can not hear the CNC machine when it is running, but can barely hear the hum of the shop-vac. And this is with the enclosure doors open.

Having a CNC room is awesome, and it looks like you are on the right path for reducing the sound. I suggest spending at least as much effort thinking about dust and heat.

Dust Collection: I have not found or even seen a “great” solution, just “good” solutions (my opinion). There are scenarios where my dust collection works really well, and scenarios where it works poorly. One advantage of using an enclosure is it reduces the range of the dust-disaster. But how do you clean the dust captured within the enclosure that didn’t get pulled into the dust collector? Despite all my efforts, I still notice a layer of dust on things in my garage. I hope your CNC room is not carpeted, and assuming your CNC room is part of a central AC/heat system for your house, make sure there is no air intake (aka AC return) for that system in this room. If you dodged that bullet, that means this room will be positively pressured when your AC is running, so make sure there are good seals on the CNC room door. And avoid cutting MDF on your CNC, holy crap the dust problem is twice as bad.

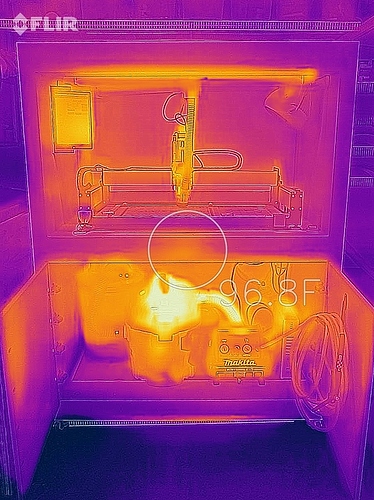

Heat: The hottest thing in my entire setup is the shop-vac. I thought I had a plan for this by building an exhaust vent into the enclosure. I have the exhaust from the shop-vac hooked up to an exhaust port. In the FLIR image below, the exhaust hose can be seen disappearing behind an air compressor. It may help, but it was not a solution.