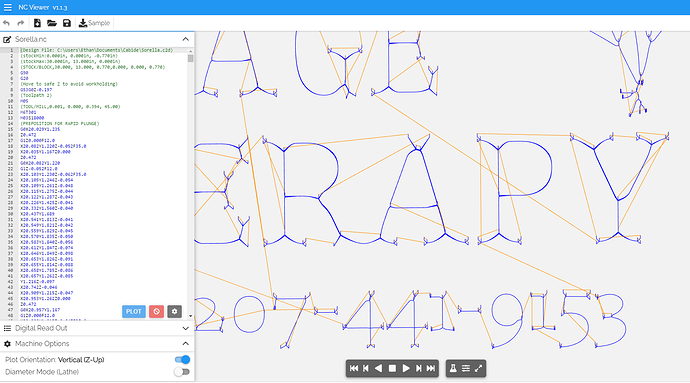

I’m still learning the Shapeoko and have tried twice on this sign. The ending letters on the three lines are offsetting. Later in the project, it comes back and cuts them in the correct spot. Any ideas what is wrong?

Hi Ethan,

Could you post the G-code file for a quick check?

I would have answered that this sounds like a mechanical problem (possibly a setscrew not positioned or fastened properly on the Y axis pulleys) but it is a bit unlikely that the mechanical problem would only occur on some letters on the right, so let’s check the G-code first.

Sorella.nc (379.4 KB)

Thanks, so the G-code is fine:

so mechanical issue it is.

You very first step should be to check all the pulley set screws, as per:

https://docs.carbide3d.com/shapeoko-faq/shapeoko-3-how-to-check-the-pulley-set-screws/

Side note: apart from this offset problem, does the preview look like that cut ? the pointy parts of the letters do not seem quite right, which usually is due to either using a Vbit with a different angle than the one programmed in the CAM, or an error in setting the Z-zero.

My error on the V-bit. I had the 60 degree in, not the 90. I’ve checked the pulley screws and they seem tight and in the correct spot.

So you made your design 14 inches in the Y direction. Assuming you have a 3 or 3XL, this is cutting it tight to the max 16 inches depth. (if you have an XXL you have plenty of space)

What I suggest is first turn off the machine and move the beam with the router all the way to the back f the machine. Then use a ruler or something to go straight down (or you can do all of this with jogging maybe that’s easier)… that is the furthest back you can cut anything

If you try to go further back than that, the machine will miss steps on the Y belts, and after that it’ll be off similar to what you are showing in your picture.

So this is a quite likely explenation if you have a 3 or 3XL

Its a 13 inch design in Y direction. I guess I’m not sure why it would come back and make the correct cuts? 3XL is the machine.

Did you monitor the machine throughout the cut and if so did you hear anything suspicious right before it went and cut the offset letters ? if @fenrus’s hunch is correct, you would likely have heard the machine contacting the front plate (judging by the direction of the offset) and going brrrrrrrr.

Is the piece still on the machine, and if so could you take a wide angle shot, to see how close it is to the front/back ?

I agree that jogging manually to the outer perimeter of that cut to double-check whether there is any mechanical clearance issue would be interesting.

one thing I will do in my next maintenance round is to stick a pencil in the collet and draw a line at the “how far it can go back” line on my spoil board… I’ve been hit on this a few times (I make quite a few 8x12 signs lately since that’s a size I can get on ebay easily, and if I do portrait… 12" can get close to the end if I stay away from the front of the machine too much… and psychology means I want to keep my cutter away from that nice metal ridge that is the front)

so at least I would suggest ruling this out please… it’s the easiest thing to rule in/out compared to all other mechanical things

SO I figured out the issue today. The right Y-belt had some extra belt after I tightened the belt some a few days prior. I believe that when the machine traveled to that spot because of the size of the sign, it was throwing off the cuts. I ended up keeping the size of the sign but moving it down, away from where the head would run into the extra belt length. I tightened an eccentric wheel too but leaning more towards the belt issue. Ran the project today with no issues. Thanks for everyone’s replies.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.