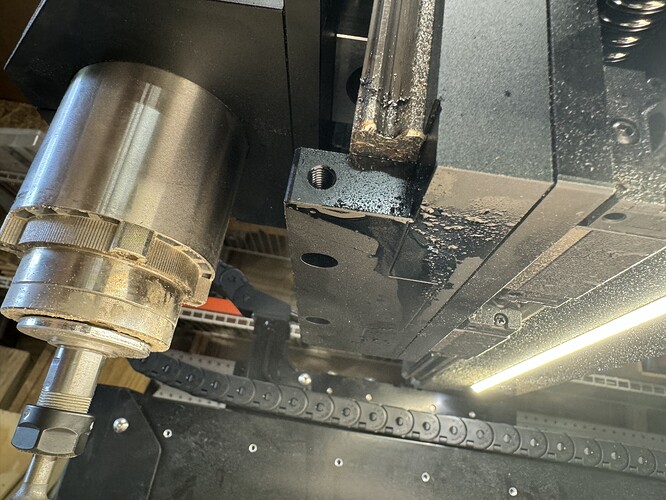

I had oil actually drop down to my work surface. Wasn’t much. The equipment has not gotten hot while using it. It’s fairly new, about a month of light use. Was wondering if it needed further investigation or maybe it’s just the Alabama summer starting to heat up and with the machine being new causing the oil to to do this.

I’ve had oil drips from the Z-axis rails of my new Shapeoko 4. They made some nasty stains on my pretty new spoilboard. I’ve been getting into the habit of wiping off the bottoms of those rails every day, and I’m assuming the drips will stop eventually.

Linear rails will get covered by oil from the linear blocks as they are used — this will accumulate at the lowest point and eventually drip — wiping things off as @KarlBunker suggested will mitigate it, but I just keep a pair of rags on on top of, one underneath the block of foam underneath my Z-axis.

When you perform maintenance on linear rails/bearings you should put a paper towel or cloth under the parked Z. Also wipe off the bottom of the linear rails on the Z-Plus and HDZ for a few days after maintenance. A new machine may drip as well. As @WillAdams said it will quit but in the mean time wipe off the bottom of the rails before use or on long jobs during bit changes to keep the oil off your project.

This topic was automatically closed after 30 days. New replies are no longer allowed.