Hello! I am a professional master pattern maker…the way all 3D things became reality before CAD/CAM…40+ years of physically sculpting objects for commercial reproduction. In my semi-retirement, I am creating sculptural pieces in hardwoods…my main material of interest is laminated bamboo…eco friendly, and beautifully machinable. The Shapeoko 3XXL has the capacity to produce the pieces I require, as I can machine the layers of my sculpture in 3 inch increments and glue them up to create the finished piece. Through a community college, I have experience with Autocad, Revit and Fusion 360. I need advice in choosing a system to create/machine my projects, including a new computer, as my laptop is 10 years old with no graphics card, etc. My experience with Fusion 360 was successful but not ideal for my goals…organic shapes are tedious to define in F360. I would appreciate any input regarding: 1. CAD/CAM software 2. A specific PC computer…ie a manufacturer/model #…thank you in advance for any information to move me forward!

I think the best options for you would be either Shapr3D or Moment of Inspiration or Blender.

Shapr3D is an app for the iPad Pro which requires an Apple Pencil and apparently a monthly payment.

Moment of Inspiration is a desktop app available for Windows or Mac OS X which was designed to be used with a graphics tablet — it is supposed to be just magical to use on a machine with an active stylus such as a Samsung Galaxy Book 2 or HP Zbook X2 (for folks who prefer Wacom EMR) or a Microsoft Surface (if you can tolerate your stylus having a battery). For bonus points, also get a Connexion 3D Mouse.

Blender is an opensource app which is supposed to have gotten much better in the most recent iteration.

Another possibility might be Alibre Atom3D — if it has nice free-form drawing tools — still working through tutorials.

I’ve had an iPad Pro for about a year now and I played it Shapr3D free for several months. Does require a Apple Pencil. (Older 6th gen iPad will use 1st gen pencil, last gen ipads use new 2nd gen pencil).

You can try out the program for free as long as you want, exports are limited and you can only have 3 drawings active. I purchased about 4 months ago the annual subscription and it works much easier paid.

There are other apps that are similar, some free some paid. Btw if you get an iPad and pencil spring for a textured screen protector. Makes the pencil act almost like a real pencil rather than slide on smooth screen.

Holler and I’ll look up the maker, (Japanese company)

Thanks Will and John…appreciate the info! I will look into those options…someone had recommended to me that Blender would be a good option for my type of work, then exporting to F360 for the CAM. Speaking of CAM, what program would be compatible for the 3XXL? Also, the computers you mentioned…do they also handle the software for the machine itself and all the rest? Old Dog needs to keep it simple…“here, Old Dog…buy this, this and this” I was interested in Vectric Aspire for that reason…pricey but has everything…though not sure I can tolerate all the tutorials with the thick British accent…LOL

If you want to get good instruction on Vectric Products, check out Mark Linsay’s excellent tutorials on YouTube, you will get the strong American accent.

Blender 2.81 should be out in days. It has a HUGE feature involving the sculpting tools I’ve been waiting for. It’ll help me tremendously.

Just curious what you’re planning on designing as it’ll help determine what tools I’d recommend?

Thanks Luc… I’ll check that out!

Hi Gary…thanks for the heads up on Blender! My main focus is on organic shapes machined out of bamboo plywood glued up into blocks…it allows me to machine the pieces by breaking them into layers and then gluing the layers together and finishing off the joints by hand…like tiling a long piece through the XY workspace only doing it vertically. One of my community college classes was using Fusion 360 to model a life size soaring gull…it was t e d i o u s drawing all the cross sections from top/front/side elevations and then lofting them together…the calculations for this process were a chore for the work station I was using…a gazillion points in space to define the shape. Do you think the 3XXL would be robust enough to handle this type of machining? The 3" Z is minimal but, since I work in layers, I can see that it would serve my purposes…

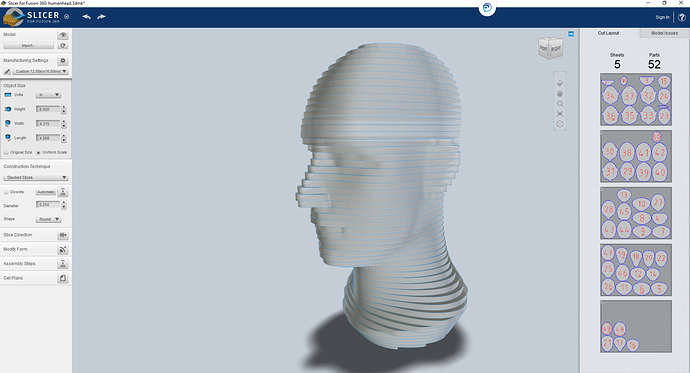

Here’s something you might want to play around with to streamline your workflow: Slicer for Fusion 360

https://apps.autodesk.com/FUSION/en/Detail/Index?id=8699194120463301363

You can start with a 3D model and slice it in different ways. The app will generate the slice shapes for you.

Paul, another thing to be aware of, milling a piece 3” in Z is a challenge unless the part tapers from wide on the bottom to narrow at the top. A few reasons for this, you’ll need end mills at least 4 inches long with 3 inches of flute, long endmills will deflect causing finish issues and also rub if the flute length is less then the cut depth.

Please also see the thread:

For CAM from most 3D apps one exports an STL and imports that into a 3D CAM app such as MeshCAM.

Very cool…thanks Roger!

Griff…thanks for the input! I hear you…all my pieces will take that into account in the design phase and, with the ability to layer my machining and choosing appropriate feed rates, I think I should be OK…I expect to do some hand finishing after machining…after 7 decades on the planet working with my hands, I’m just looking to get the pieces close and save some wear and tear on the old joints!

Thx Will…I’ve heard good things about ZBrush and I appreciate the CAM info…communicating with the group comes at a really good time as I try to wrap my head around this next challenge…thx everyone!

Question about scanning and/or digitizing probes…I have some master models in MDF that I have been using to produce sample pieces using a Duplicarver. I have seen digitizing probes available for creating the G code off of physical models…would this be possible with the 3XXL? Have also seen some Lidar scanners available…???

Paul:

One thing you have to realize and it certainly was not clear to me at the beginning is that the Shapeoko with the standard mount will only have some 3in of Z travel under the gantry. The HDZ bring this up to 6in but if you have a model that is say 8in (Z), you would not be able to digitize on the Shapeoko and creating it would mean making two sides and gluing it together. There is a bit more room in front of the frame but it is restricted to a couple of in Y and would require special a holding jig. A 4th axis would further reduce the height available.

Thx Luc…yes, the 3" Z is a definite constraint that I have decided is not necessarily a deal breaker, as I will be using glued up bamboo and baltic birch plywood, so I can “slice” my sculpts into units and then glue up the finished piece and finish the joints by hand. What is your experience with the machine’s robustness ie how does it handle a material like hardwood?

I have an XL, I have done some 3D in hardwood with good success but I mostly do 2.5D work so far. If you stay within the limits of the machine, it provides very good results and if you are @Vince.Fab or @RichCournoyer, you get great results. I’m still wearing little boys pants compared to those guys

Luc…you mentioned the HDZ…first I’ve heard of that. Looks like a great potential addition but working with laminates, not something I would think I need to start with…

Hey Will…looking thru the topics, I noticed mention of “metal belts” on newer machines…could you explain what that means? I was assuming the drive mechanism uses fiber reinforced rubber belts…