So I am no expert in this domain…but I think I have an interesting perspective so I thought I should share.

I bought a Pro 2 months ago and it was my first foray into CNCing. It has been amazing, but every task that you need to do takes 10x the amount of effort than you actually think it does.

Some of this is learning curve, some is just it looks easier than it is, and some is babysitting the machine while it’s making it’s 6 passes and lots of retracts.

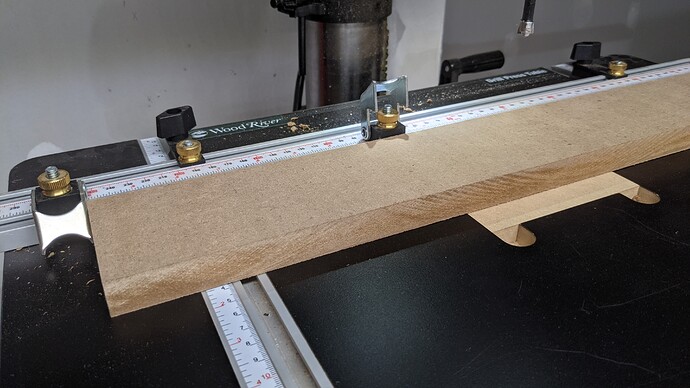

Which leads me to the comment about the table base. The Pro comes with MDF slats with four perfectly spaced holes that fit into the t track. Due to errors, I have just about killed my MDF slats. The effort to remake these, along with all the other things I’m doing during this learning experience is enough to make me cry. The comment about effort and expense that @SLCJedi makes is completely true.

So based on the fact it would take me too much effort to make the MDF slats I reached out to carbide and just ordered new ones. Why do I tell you this? It is to highlight the amount of work associated with table base. While it seems easy, looks are very deceiving.

The other thing that looks easy, but is not, is enclosures. I’m probably a week away from sharing mine in this forum, but every detail takes time to design, if you can order premade, that would be a great selling point.

The one thing I have also learnt, as I troll the various boards, is that the forum/community is the most important thing. There are going to be a million bumps along the way. You need to be able to look at historical questions and answers and have a place for new answers. (Complete side note, but @neilferreri how do you have time for so many forums and on different machines).

There is one thing that would make me choose a BRAND X over a Shapeoko. That is if BRAND X would accept 4ft wide plywood. The amount of MDF/Plywood waste around my garage is amazing PLUS every time I want to start a job, I have to cut of the plywood first. It is painful and I know I’m not alone in my frustration.

(Related but Completely different tangent…Home Depot will cut plywood for you (albeit incorrectly) using their panel saw, but Menards won’t. Yet at menards their selection is so much better and cheaper. My solution…When I wheel my cart out to the parking lot, I pull out my battery powered circular saw and rip it right there in the parking lot. The stares and claps I get are awesome…Makes it easy to load in the truck and unload it into my workshop

FYI - I’m sure I’ll think of something else later and want to edit this post…also, if my grammar is off, that is the dangers of using iPhone posting, autocorrect and one finger typing leads to the worst Grammar and autocorrections ever