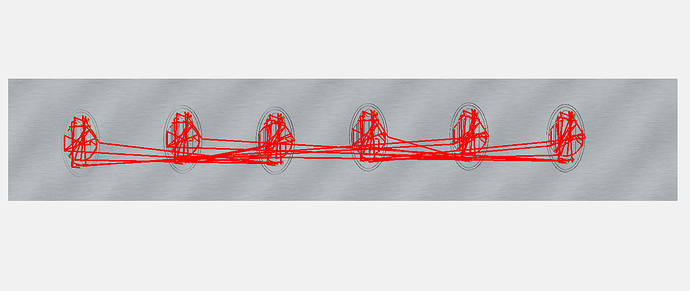

Is there any way to optimize the tool path route as opposed to having the machine bounce around across the workpiece, in turn lengthening the machining process.

Can you:

- Share an image of what you’re seeing

- Let us know what version of CC you’re running

- Post your file?

ac milan coasters.c2d (1.8 MB)

Check out the Vcarve and how the toolpath doesnt just stick to ones completion and then move onto the other.

I am using the 629 version of CC

Not that this is an excuse, but from the software’s point of view there is not discrete item to complete, and no other one to move on to. It’s all one set of points.

When assigning the tool paths, do you have all cuts grouped under one path?

If so, I would assign each section to it’s own tool path so it finishes each section before moving on to the next.

I tried an example with lettering, and I did notice a difference if I selected the vectors one at a time in order rather than selecting the whole group at once. It wasn’t logical, but it was a bit better as far as optimization goes.

That’s interesting.

Perhaps some simple positional sorting (horizontal or vertical) in CC when generating toolpaths for a group of objects would cluster the operations a little better?

Ooooh that’s a really interesting idea

I think this will help the situation but overall is something that can be fixed within the software itself

I’m not sure if any of you have used the vectric software, but that program has the tool path optimization I’m talking about.

I prefer to stay for the growth of carbide, which is why I am stating an issue I see instead of dropping the program all together

The bCNC gcode sender has a “rapid motion optimization” in it’s gcode editor, I looked at it briefly a couple years ago. As I recall it would break gcode files into blocks based on raising Z out of the material, then arrange those blocks using a traveling salesman optimization, but with no vector direction changes. Estlcam has a built in simple optimizer that I’ve used but not really analyzed. There’s cnctoolpathoptimize on github that looks interesting, the readme says it was a class project from 2016. A web search turns up a bunch of interesting stuff along with lots of comments on how it’s a difficult or impossible project. Adding youtube to the search finds a video on CNC ant colony optimization, which should win some points for a cool name. And I pretty regularly use md8n’s GCodeClean (from github, for some reason I keep wanting to call it gcodetools which is a CAM inkscape add-in) to convert retracts to G0 and turn short line segment curves into arcs, he’s a member of the Maslow CNC forum and used feedback from there to help develop the tool.

Jasper the difference between cc and vetric is about $350.00 to $0.0 Not an insignificant amount. For Aspire the difference is about $1200.00. For that amount I would expect more. The good news in the last 3 years c3d has made significant upgrades in cc. Not yet up to vetric but pretty good for me.

This topic was automatically closed after 30 days. New replies are no longer allowed.