Do you think that putting lacquer, shellac, polyurethane or urethane over the paint would address the residue issue?

For the Oramask it may? I would have to use a spray lacquer, as the brushing lacquer acts like thinner on the paint.

OK I have two pieces of MDF spray painted drying and I will test the clear lacquer on one of them with the shelf liner.

Have you had issues with the lacquer bubbling the spray paint? I tried using clear lacquer to seal a piece of wood, then engrave it and then spray paint it, but the paint bubbled where it made contact with the lacquer.

I had to buy clear spray paint to seal wood when I spray paint it after.

Sorry for the slight derailment, just wondering if it was the specific lacquer or paint combo I used. (Varathane satin lacquer technically, it is [oil based] Polyurethane and Rust-Oleum paint)

Sorry about this, I used Krylon clear acrylic gloss on RustOleum semi-gloss spray paint. I thought it was lacquer from the smell but the small print on the can says otherwise. The finish is excellent for my test, no bubbles. I’m waiting until tomorrow for the paint and clear coat to harden before putting the shelf liner for the test. I wanted to take a picture but I can’t get a good picture with my phone, too much reflection on the paint.

I ended up carving another one and then using some Dutch boy premium paint for the black and when it dried the vinyl peeled up with no issues at all

You carving looks great. I am not familiar with the organization but have ridden in a few C130s in my Air Force life. I even got to ride in a Spooky once during a live fire exercise. Wow what a ride, my ears are still ringing.

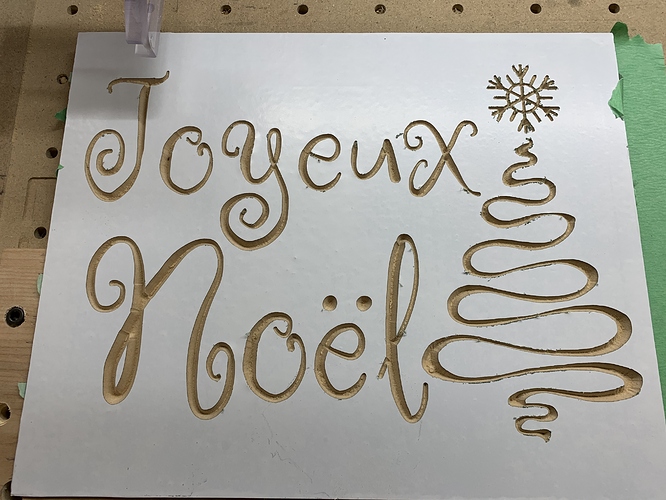

OK, I tested the use of Duck Brand white adhesive shelf liner for carving/painting.

Method:

I made two samples for this, one had 2 coats of semi-gloss spray paint background covered with shelf liner and the next one had the same paint with a gloss acrylic clear coat.

24hrs after they were painted, I put the clear coat on one and let it dry for 12hrs then I applied the shelf liner on both. I used a scraper to ensure good adherence. I waited another 24hrs before I started carving.

I carved the one with clear coat using 60 deg Vbit, a 0.125in flat endmill and a 0.0625in flat endmill, the other I used only the 60 deg Vbit.

The mask stayed on perfectly in both cases, there were a few fuzzies around the cuts but they were easily removed with a utility knife and a scraper. At the end, the endmills were clean with no gum-up residues.

After they were cleaned, I put on acrylic and latex paint in the carved areas and let it dry for a few hours.

I easily removed the mask and there were no residues left behind on either project. The surface was smooth, the mask did not pull the paint. The paint lines were generally crisp but to be picky, there was just a bit of bleed on the project without the clear coat but you have to look at it very closely to notice.

All in all, I’m very happy with the results and I would recommend the shelf liner as it is cheaper and more available than Oramask 813.

Luc, thanks for the fine example. Unfortunately, nowhere do I see a Duck brand item number anywhere, and both Amazon and Walmart have many types and colors available. Could you post a more specific reference to the liner? Thanks!

Tex:

I’m in Canada and I went to the store but looking at WalMart’s website in the USA and I think that this is the same one judging from the image and comparing it to the one I posted above. I think that at $5.50 for a roll, it worth buying it and testing.

I am curious as to this process of art work.

Is the wood first painted with a base coat of paint.

Then a mask is laid down on top of the wood.

Then the wood is engrave or carved.

Then a paint is sprayed on the engraved/ carved areas.

Then the mask is removed exposing crisp straight lines of painted surfaces of the art design.

Thanks, Luc. Looks like this (Walmart # 573118705) is an exclusive Walmart product. There probably is the same one available elsewhere, but not with the Duck Brand Manufacturer Part Number of 286444. For that price, I’ll risk going to Walmart for it!

More or less you have the process described. I have painted by hand but spray paint would work too except if you do 2 colors, you would need to mask the area you don’t want painted. After I remove the mask I would also apply a clear to protect the paint.

I think that letting the paint dry overnight is an important step as is the use of a smoother or credit card to press on the mask to ensure good adhesion.

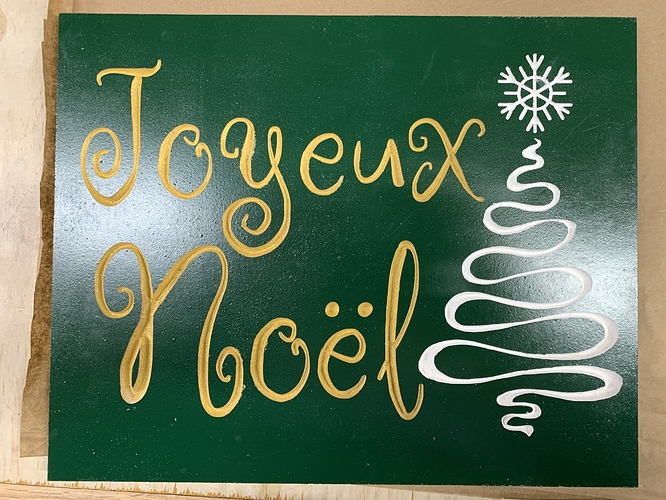

I had really good success with the shelf paper this weekend also. I usually have to leave the mask on for at least a couple of days before I can get back to it to do the painting or peeling, and I think that was my biggest problem before. I had the time to do this one complete in one day, and I did not have near the adhesive residue I have had in the past. Here is my procedure on these:

Lacquer the wood. Sand to 220 after lacquer is dry. Apply mask. Carve. Apply lacquer to the areas that get paint. Paint after the lacquer is dry. Peel after the paint is dry. Sand to remove any adhesive residue. Finish with mineral oil.

There was very little residue on this one, so the finishing sand was really easy. I’ve never had problems with the shelf liner sticking, and getting really good detail. Check out the “Tee” and the “Top”

So it looks like if I don’t leave the paper on too long the shelf liner works just fine.

Were most of the comments with people using MDF or wood.

just wondering.

I used MDF for my tests but I doubt that it makes much difference with the right paint/preparations

@luc.onthego I used the WalMart shelf liner masking technique on my sign project here in the Gallery.

At that price with good results, why pay more for Oramask?

Ive been working with a product lately that I used to use in the signage biz, and found some new uses in the automotive world. Its made by Gemini, and is called Duets. Its an ABS substrate, with different finishes, and some of them have a color core, so all you have to do is go down below the surface (usually .1mm or so) and the results are really good, especially on my laser. It cut great with my dewalt set to 10K, and using the feeds suggested in the wiki. I did a couple with a v bit for a chamfer, until the client decided that the time /cost was too high and he just wanted laser cut shapes.

Similar to the old-school engraved nameplate material, I presume?