Between visiting family, late-stage prototype troubleshooting on a couple projects and tuning my Shapeoko, I’ve been away from here for awhile. The late-stage prototype issues chewed up a tonne of time; honestly feels like the last few issues are always the hardest to solve. But solve them we did.

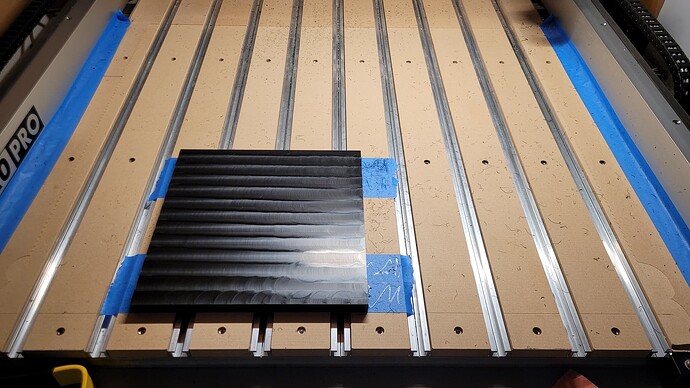

Speaking of solving, I finally have a well-trammed Shapeoko. I thought it was good before, but she’s purring like a kitten now and facing ops are just so smooth and pretty:

Notice I’m back to using painters tape. That’s temporary: this piece of Acetal will become my new vacuum fixture. The OG vacuum fixture was “flat enough” for the pre-tuning Shapeoko but as soon as I fitted it after tuning, it was clear it had adopted all the faults my machine previously had.

Tramming was a day-long affair. First I followed this quide from SamCraft (How To: Shapeoko Pro Calibration, Tramming & Surfacing | CNC Router Woodworking - YouTube), to get a flat reference. I used an aluminium plate at first then switch to a sheet of plate glass after my dial indicator showed just how uneven the aluminium plate was. Here’s the toolkit for this op. The 1-2-3 blocks are from Amazon, the dial indicator and tramming arm are from PwnCNC. Together they were less an CDN$60 but worth it.

Once the machine was dialed in flat, I surfaced the spoilboard 0.25mm in the whole cutting area. I used a 1/4" flat end mill instead of my Amana surfacing bit because any slight tilt in the router would result in some ridges but not as deep as with the larger bit.

Once the surface was flat, I then spent the next half day dialing in the router tilt using a cheap set of feeler guages from Princess Auto (our Harbor Freight here in Canada). For any electrical engineering people, I used a approach called successive approximation: I didn’t know how much tilt existed so I used the dial indicator and arm in the router to measure it (same as in SamCraft video). Once I know the rough magnitude and direction of tilt. I chose a random feeler guage and inserted in between the router collar and the z-axis plate at the bottom of the router collar (my tilt was backwards in the y-direction). After that reinsert the dial indicator and measure again. If the tilt went in the opposite direction, the feeler guage is way to big so pick one half its size. If the tilt was reduced but not enough, pick once 50% bigger and try again.

While adjusting tilt, I had to keep using the 1-2-3 blocks as supports on each side of the router. That way I didn’t lose the “parallel” tram while trying to fix the tilt.

After all this, the moment of truth was surfacing the acetal this evening. The whole tramming experience was long and painful but absolutely worth it, just to feel the surface finish on the part.

Posting this to help others but also in case someone has a faster way to do this.

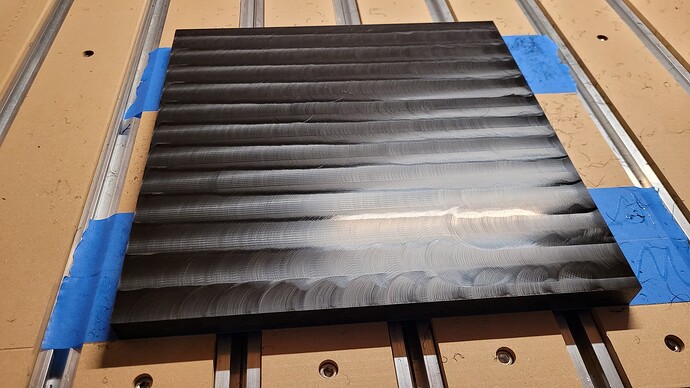

PS: Also figured out how to fix the fuzzies when cutting acetal or HDPE: just up the RPMs and/or feed rate and stick to climb milling. On the pic below, the first few passes were at 11,000 RPM. Notice the consistent sworls. I upped the speed to 18,000 RPM for the remainder of the job and that fixed the problem. My feedrate was 1400 mm/min and I’m using a 1 1/2" Amana spoilboard cutter (RC2249).

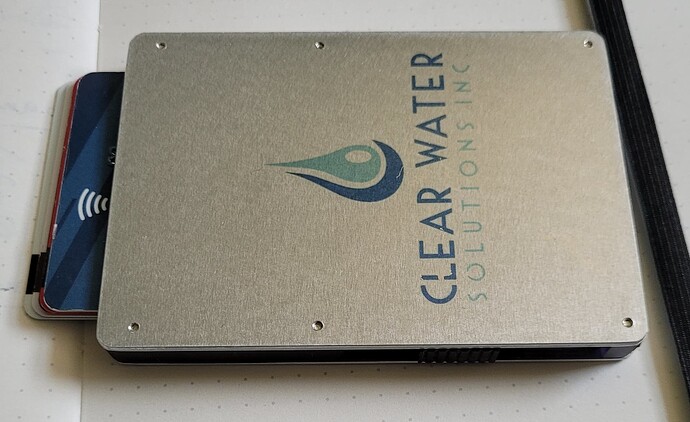

Now I can finally get back to doing more of this:

PPS: This formula might help when figuring out the when to stop tramming for tilt:

h = R_em * (T_d / L)

T_d = height difference as measured on the dial indicator

L = length of tramming arm as measured from the center of the router collet to the indicator pin, parallel to the spoilboard

R_em = end mill radius

h = the size of the surface deviation for the given end mill, resulting from the tilt still on the machine.

I stopped when my h value dropped to 0.03 mm for the 1 1/2" surfacing bit. I can’t feel a deviation that small and for most of my parts, that is well below tolerance needed; especially given that it drops to 0.005mm for a 1/4" end mill.

Hope this helps.