Hello Carbide 3D forum,

I have been using the Nomad3 to mill PCBs and am looking for some advice. I’ve had success using FlatCAM to generate gcode and Candle to generate height maps to create very precise circuit boards. I’ve made both single and double sided boards.

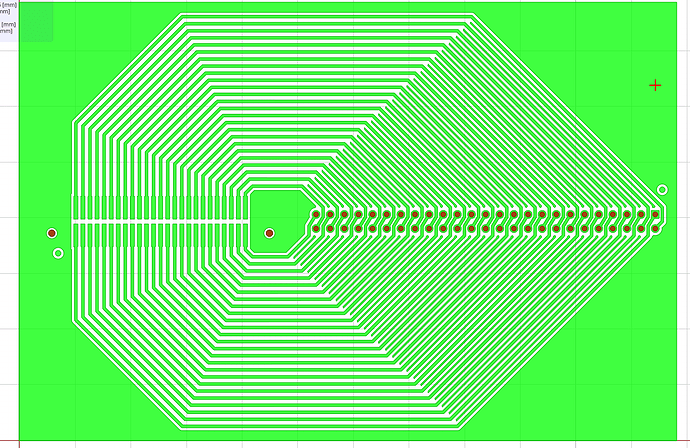

I’ve included a picture of a PCB gerber in FlatCAM below, which takes up most of a 4"x6" board. Using the #501 vbit running at 10 in/min at 12,000 RPM this board takes an hour and 20 minutes to mill. Are there any suggestions on how I might be able to speed this operation up? If not, is it safe to leave the machine unattended during the operation?

Also, how long do the #501 and #502 vbits typically last? Seems like they wear out after a 10ish boards. Is that to be expected? Perhaps my feeds and speeds are causing premature wear?

Thanks for your advice!

-Jeremy