It’s been a while since I was here sharing. I am always amazed at what you guys come up with. I was machining some parts on my old Shapeoko 3 and it was a long cycle. So I started cutting other parts for the project with my plasma cutter. As close as I can get to multitasking. Anyway I cut the parts and went back to the machine and I guess the interference from the plasma cutter confused the Shapeoko. It just said busy. So How can I make this better? The answer came from a YouTube. https://www.youtube.com/watch?v=idKb246qnAk&lc=UgwTCAxVanQNuyUx0-R4AaABAg

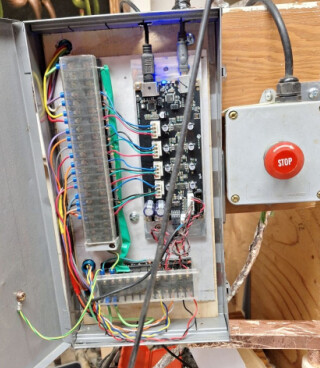

So I went crazy and soldered a bunch of 4700pf ceramic capacitors to every wire connection in my control box. One end to ground out the EMI. And it worked. No more EMI.

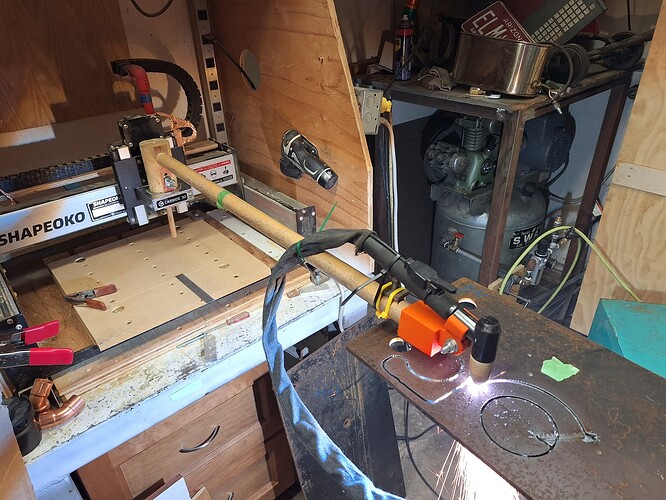

Then I started looking at all the parts I had to cut out of steel plate and said I need a cnc plasma cutter. I made wooden cylinder to fit the Shapeoko mount in place of my Makita. Then I mounted an old plasma cutter gun to a 48" long handle to that. The crazy thing works. Not great because its not a pilot ark. Using carbide create and carbide motion with a little edit in WordPad and it strikes the arc and cuts very fast. I will post a few pictures and a video if I can figure out how to do it.