Started my pocket cut and machine messes up! Start position of the cut moved 4" in the middle of the cut. No explanation. Working fine and wood did not move. See pic…

What could have gone wrong?

Most likely lost steps — what are you using for feeds and speeds?

Did the machine run out of travel?

Are your belts and pulley set screws adjusted/tensioned?

60 feed with 23000 rpm

Did not run out of travel. Almost acts like the material moved but it couldn’t have move by 4". Also when I went into check my zero, it went right back to the corner in the correct spot.

Belts and screws are all checked and secured.

I ran a couple more smaller projects and everything is working fine.

My bet: possibly a semi-loose setscrew on the X axis motor pulley

I was back at this…checked everything, made sure everything was clean and did notice x belt was feeling lose. Tightened it up and started job. Flag stripes shifted with 1/8" bit @ 10000 rpm, 550 feed rate…checked everything again and belt felt loose again. Is this because it is new machine and belt stretches in use or something else I should be checking?

It’s not supposed to get loose that fast, it at all (I only tighten my belts every 3-4 months)

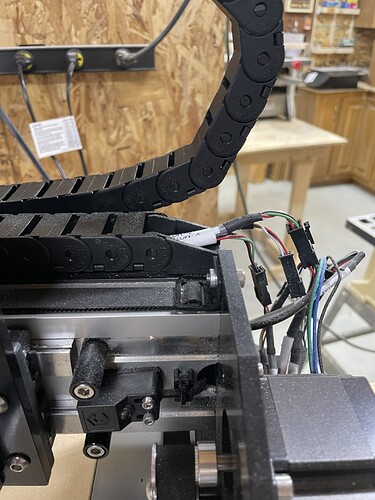

Can you take a picture of the belt clip and how the belt sits in it ?

Can you precise what you mean by “felt loose” ? approximately how high can you lift it with your fingers if you lift it in the middle, when the gantry is at one end of the axis?

Another note…when I went back XY home position, it is right on and not shifted.

Belt was lifted about 1" to 1.5". No after tightening it can be lifted to 1/4".

Allright, that sounds more than enough (the 1/4" mark). Anyway loose belts will tend to produce irregular shapes, but will never produce sudden shitfs in the cut. Can you share a picture of that last shift you had?

Is it shifted along X again ?

Did you have a chance to double-check the X axis pulley ? (I now, it’s not fun to access it on a Pro…)

Can’t load images for this reason…

Sorry, new users can only put one embedded media item in a post.

What am I checking on the x pulley?

Yes just the x axis was shifted and to the right just like last time.

Also this is longer jobs when this is happening. Smaller simpler cuts are turning out fine.

Could this be a Motion software issue and not a hardware issue?

Seems very unlikely, since there are a lot of folks using Motion (more than Create)…and are not experiencing the same issues.

I was thinking maybe a local thing and needing a reinstall as opposed to the overall software. Just trying to troubleshoot.

I upgraded your account, you should be able to now.

The X stepper motor pulley has two setscrews, and for the machine to work properly without any shift, they must be tight, and one of them must be properly aligned against the flat on the stepper motor’s shaft. There is an illustration on how to check it but it applies to earlier Shapeoko models:

https://docs.carbide3d.com/shapeoko-faq/shapeoko-3-how-to-check-the-pulley-set-screws/

On a Pro, I am unclear on the exact steps required to access the X pulley, at the back of the Z-plus. @WillAdams or supprt@carbide3d.com should be able to help

I got to the pulley and there were 2 set screws. Each one turned about a quarter of a turn for further tightening.

I am going to run another job to just wipe the surface of my project to start over but this will be a good test and see if tightening helped. Also will see if belt gets loose again without ruining another project.

did you have a chance to check visually whether one of the two setscrews was aligned against the motor flat ? Not quite easy to see, but vital to the correct operation of the X axis.

Yes one is on flat edge