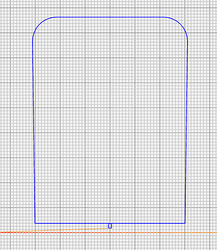

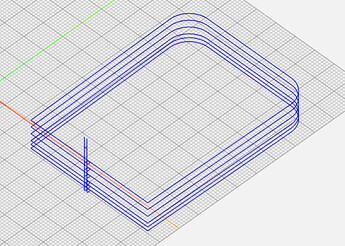

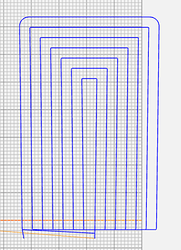

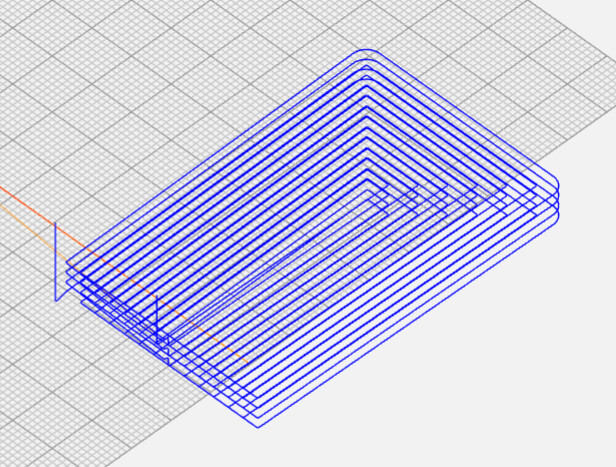

@AmateurHour Matt, check out ncviewer.com. You can load your files there and check your gcode. Both files look good as far as I can see, nothing in the gcode telling it to do something weird. Cut depths look reasonable.

That wobbly cut you showed pretty much guarantees a mechanical issue, as @Ensalaco called out.

- Stretched or loose belts are a good starting place

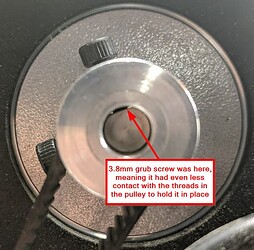

- Check your pulley set screws, I had a very similar problem that was caused by the pulley slipping (right pic credit @Zman

)

)

- Loose v-wheels will cause this too

- Dull bits or overly aggressive feeds can create extra drag and missed steps (mentioning because your cuts don’t look very clean, but that might be the wood more than the bit)

As @WillAdams mentions, all of these issues will be exacerbated when you have a deep narrow slot. Play in your system will cause it to grab into the material.

An easy check is to power on the machine which locks all your motors. Now push on each axis. ANY movement at all is bad, it should feel solid. Grab the z axis, rock back and forth, front to back. Any movement there is bad. Check each v-wheel, it should be tight against the frame.

I went through this last fall, after a long period of deferred maintenance. My belts were stretched, some missing teeth. My v-wheels were loose. Router bearings were shot. Handful of other problems. Spent some time repairing those issues and everything is tight and working probably better than new.