I have an issue I’ve been dealing with for weeks and cannot get figured out. I’ve emailed support and they have responded, but I’m lucky if I get one email response a day and now we are headed into the weekend, so I’m hoping to get some additional help here.

My problem is missed steps, which I assume is being caused by a wierd power pulse im getting…heavy on the assumption here.

I have triple checked the following:

Belts are equally tight

Set screws are tight

Machine squared and trammed

All machine bolts are tight

Table, router and vac house are all grounded

Router and machine both run on their own separate circuits and are plugged into EMI power surge protectors.

I discovered the power pulse when I left the machine on while I worked on a file. It randomely started sounding like it was rapidly powering on and off. The light on the power switch would flicker as well. The blue light on the control board would stay lit and would not flicker.

I checked all the wiring for a loose connection and everything is tight. I went through each wire individually thinking if I moved it around, I would be able to duplicate the sound from a possible short but no dice.

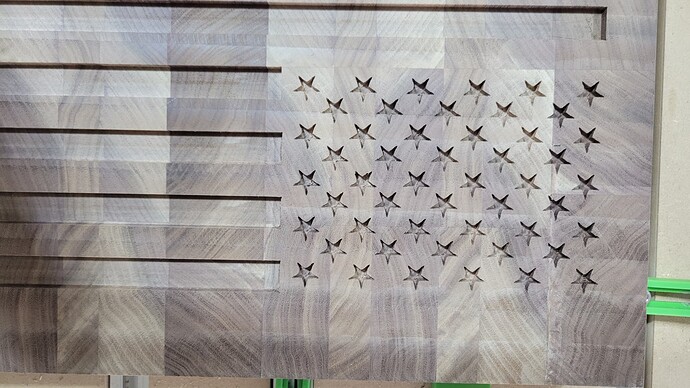

I feel like the randomness of the pulse is what is contributing to the missed steps on a job. I ran a 3.5 hour job on a flag inlay and it ran flawlessly the entire time. Set up a new job for the pocket and it carved random pieces all wonky. See the stars in the pic. Some stars were perfect. One was all jacked. The others missed steps enough to cause a rounded i side point.

Has anyone ever had this issue? Im considering a power conditioner or UPS, but if this is a machine or motor issue, id rather have cardibe3d replace it before i spend a bunch more money.

Everyone raves about their customer service, but I have not had much luck so far. I get one response a day via email and have to wait another 24 hours to hear from them. The first person I was working with disappeared and now another one has taken his place. There’s only one day a week I can do a video chat, due to my work schedule, and I have that scheduled for next week.

Their last request was to “Send a video of the problem”

The problem with that is the power pulse is so random and so short, it’s impossible to get a video.

Any thoughts??