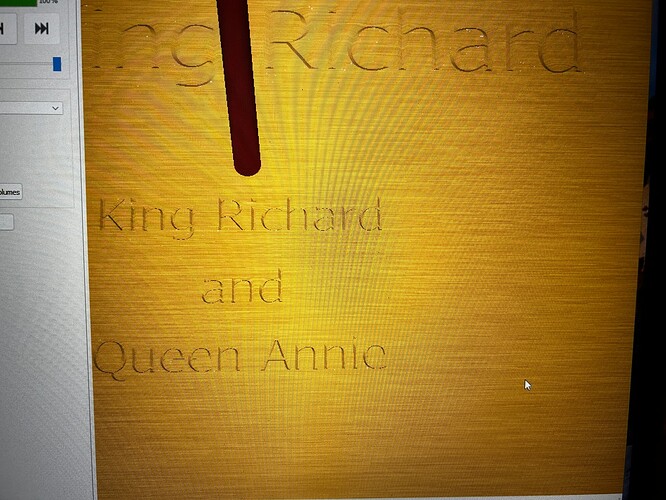

Testing fonts using 90 Vee-bit. Top font works but not deep enough and the bottom doesn’t even scratch the wood. Both are set at 1 inch depth on a material thickness of 3/4 inch. After reading a few posts, thinking this could be the font BUT the preview looks good. Should we be using an engraving bit. Cutting on a Shapoeko 5 Pro.

Suggestions welcome!

Is this a V carving?

Draw up the tool in profile and the width of the widest section of lettering to see how deeply the tool needs to cut to cut that width.

If you want a deeper cut, use a more acute V tool.

The ‘Depth’ for a VCarve is NOT how deep it will cut, it’s an upper limit to how deep it will cut. The depth is calculated along the cut so that the V bit touches both sides of the vector you are cutting. If the vector is very wide, the ‘Depth’ setting prevents the bit from plunging ridiculously deep.

Simple vcarving should always use bottom of material. A simple vcarving only goes as deep as the bit will touch both sides of the lines. On thin material and thick lines you can cut through the material but on thicker material that is not a problem but depending on the width of your letters the bit will only go down as far as it need to touch both lines. The 90 and 60 degree bits will barely scratch the surface on very thin lines. If you have very thin lines you need a 30 or 15 degree vee bit. Limiting depth on a simple vcarve can cause unusual output. Should you ever need to limit depth use advanced vcarve. An advanced vcarve will use a flat end mill to carve out any larger flat areas and the vee bit just goes around the perimeter of things.

So on a simple vcarve use bottom of material in the tool path. The vee bit will only go down far enough to touch both sides of the lines. Thin material you can go right through and in the simulation the bottom of your carving will be white showing you went through the material. On thicker material but with thin lines use a smaller angle vee bit. You may need to pick a different font if you want to use a 90/60 degree vee bit to get deep enough cuts to show up well. If space is limited and you have fine line fonts or small size fonts then go to a 30/15 degree vee bit.

Since the letters are quite thin and the bit will not be cutting very deep, consider that the stock may not be perfectly flat. If you set Z zero on one end of a board that is 0.02" thicker than the other end, then as you move along to the thinner end the cutter isn’t going as deep. Even the S4S (surfaced all 4 sides) you get from the store can have a thickness difference of +/-0.010", or more.

This topic was automatically closed after 30 days. New replies are no longer allowed.